60x60 Ductile Iron Manhole Cover and Drain Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 3900 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

Material: Cast(Grey) Iron (GG 20, GG 25) and Ductile(SG) Iron(GGG 50).

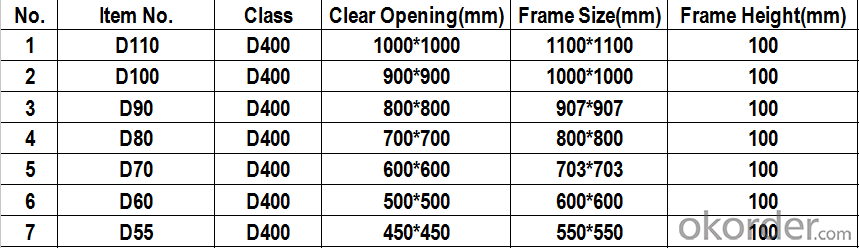

Sizes: 300 mm X 300 mm (11.81" X 11.81") clear opening to 1200 mm X 1200 mm (47.2" X 47.2") clear opening.

Load Rating: A15, B125, C250, D400, E600 and F900

Painting: Black Bitumen, Epoxy and other paint as per provided by customers.

Other Features: Hinging, Locking provision available, Leak proof and customized designed available.

Pictures

Specifications

Our Company

CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers. Our customer come from America, Morocco , saudi arabia, Iran , Algeria and so on

CNBM Ductile Iron manhole cover A15-F900 complying with EN 124 Standard

FAQ

Why imported Composite Manhole cover/Grating from China?

1. Very competitive price, it will save you third or even half cost.

2. Good quality, don't worry much about the quality, actually, most of the building materials you buy from Miami, Dubai, Italy, South Africa or your local market are imported from China. So why not buy direct from?China. The key point is to find a reliable supplier who is honest and professional to take care of the quality and delivery time.

3. Chinahas full range of Manhole covers which Follow En124 for your market, like A15, B125, C250, D400.

- Q:How to improve the surface roughness of casting parts?

- One is to improve the accuracy of the model; the two is to improve the molding sand mesh. How much is the other relationship?.

- Q:Why do cheap cars like stamping parts instead of casting parts?

- Separation process is also called blanking, the purpose is to make the stamping parts along a certain contour line from the sheet metal separation, at the same time guarantee the quality requirements of the separation section. Stamping is a highly efficient production methods, the use of compound die, especially the multi station progressive die stamping process can be completed in a multi machine, realized by belt uncoiling, leveling, punching, forming and finishing automatic production. High production efficiency, good working conditions, low production costs, can produce hundreds of parts per minute. The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning, and straightening are the main types of stamping machines.

- Q:How to solve casting defect casting?

- Different defects, different solutions, some shortcomings, the current domestic level can not be resolved

- Q:What are the factors affecting the machining process of the casting material and structure?

- The impact on the machining is obvious, it should be the material and heat treatment of the castingCarbon steel parts should be treated by heat treatment (annealing) without special conditions. It can effectively prevent the uneven hardness and hard points. It is easy to turn.

- Q:What kind of flaw detector is better for casting parts?

- If you want to detect internal defects, you can use ultrasonic flaw detector, ray flaw detector can also, but the ray of the safety protection level is too high, not recommended priorityMacro Xu flaw detector answered, such as the magnetic particle inspection machine has the demand can contact us, Baidu "macro Xu flaw detection""

- Q:Can the casting part be phosphating with the phosphating solution of the pickling board?

- If it is Phosphating for painting, it is not necessary, because the surface of the casting is rough and can be firmly bonded with the paint film.

- Q:The casting sand is going on

- 3, prevention measures(1) to improve the strength of sand mold (core), especially surface strength, high temperature strength, refractoriness, compact, better coating, good core coating and parting surface coating.(2) mould and box can prevent damage;(3) the core should have clearance.

- Q:Casting parts have poor surface finish. What sand is used to make them?

- Manual coal dust, clay sand is a little worse. Mechanical styling is not bad either.

- Q:I often see Waixiejiagong drawings, casting, how to distinguish the latheman.

- Casting rough drawings generally no processing symbols, processing drawings indispensable is processing symbols!

- Q:How do you mark it on the drawing? Do you need to discuss it with the manufacturer?Because the casting allowance is the standard, then, after all, is the theoretical value, the actual level depends on the manufacturer, so is it necessary to ask the manufacturer?

- The general foundry casting technology division will mark put shrinkage and the allowance of the map in your chart (usually with the red pen) for the production of wood or other material wood workers die drawings.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

60x60 Ductile Iron Manhole Cover and Drain Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 3900 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords