Professional vsi crusher,sand making machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

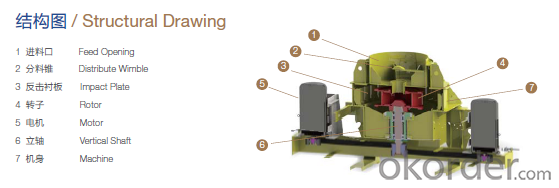

vsi crusher/sand making machine widely used in mining industry Our vsi crusher/sand making machine is especially efficient to crush harder and causticity materials, such as carborundum, emery, and magnesium sand. LY vsi crusher/sand making machine is one of the most advanced impact crushers nowadays. It introduces high quality roller bearings, which ensure the smooth running of main unit. Personalized design is used in upper cap, vsi crusher/sand making machine is easy and convenient to maintain and replace spare parts. vsi crusher/sand making machine is our sole patent using central feeding & central cascade feeding, which can be changed based on customers' needs.

vsi crusher/sand making machine working principle The entire center feeding: Material falls the feed hopper, then enters the high-speed rotary sling wheel from center feeding hole, which is speeded immediately in the sling wheel. The speed can reach several dozens times of the gravity acceleration. Then vsi crusher/sand making machine is thrown from the sling wheel. First, it is crushed with other rebounded material fell freely from the sling wheel. Then both of them are impacted to the material lining (rock-rock) or strike back block (rock-iron), rebounded and stroke to the top of eddy cavity of vsi crusher/sand making machine in the inclined-up direction. Then it moves along deflection-down, and forms a continuous material curtain with the material from the impellers passage. Just like this, the material is stroke, rubbed, crushed twice or more, then is discharged from the down discharging hole.

Main Product Features:

1. The structure is simple, and the operating cost is low.

2. High efficiency, and low consumption.

3. vsi crusher/sand making machine is slightly influenced by the humidity of material, and the max humidity is 8%.

4. vsi crusher/sand making machine is more suitable for crushing mid-hardness materials and high-hardness materials.

5. Its product is cubic, and the density of piling up is high and the iron pollution is low.

6. The working noise is less than 75 decibels and dust pollution is little

Product Specifications:

| Model | Max. Feed Edge (mm) | Rotor Diameter (mm) | Processing Capacity (t/h) | Motor Power (kw) | Rotor Speed (r/min) | Weight (t) | Overall Dimensions (L×W×H) (mm) |

| PL-700 | 30 | 700 | 20-60 | 2×90 | 1400-1850 | 7.9 | 4170×1982×2191 |

| PL-850 | 40 | 850 | 80-130 | 2×132 | 1200-1450 | 14.2 | 5040×2250×2800 |

| PL-1000 | 50 | 1000 | 120-180 | 2×160 | 1250-1350 | 16 | 5236×2362×2740 |

| PL-1300 | 60 | 1300 | 180-300 | 2×200 | 900-1000 | 20.6 | 5760×2580×2980 |

FAQ:

Q1: How to confirm that your crushers could be used in our site?

A1: We have been providing crushers for more than ten years, and cooperating with the agent of the world famous brand, possess near every kind of bend in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 15-30 workdays.

Q4: If we can produce some crushers according to customers request?

A4: Yes, we can produce crushers according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q:invested 32000 cash and equipment valued at $14000 in business

- The following journal entry will be passed for the transaction: Dr Cash ...................... ........... $32,000 Dr Equipment ........................ $14,000 Cr Capital ................... ........................ .............. $46,000 . .

- Q:katherometer is used as detector in Gas chromatography.Why.?

- This is the hardest part. Sadly, you'll never really know if he did it or not, he has lied to you a lotso it's almost impossible to believe. What you can do is go to a counselor, so you can get through this stuff, and then decide if this is worth it or not. I think your hunch is right, he had to have cheated with the things he has said to you, even my fiance agrees. No man who is in love with his wife will cheat, regardless if he has the chance or not. You seem very loyal and smart, you deserve so much better. Stay away from people's opinions during this time until you can figure out what you want/need to do. If your hubby has a reality check, like a serious one to see what life will be like for months without you or even talking with you, it may be of help. I do recommend you taking the time to figure out what to do. Good luck and I wish you the best.

- Q:Out of these 4 mascaras, which of them is your favorite and why? I'm trying to look for mascaras that will help lashes look longer, thicker, and NATURAL without clumps Please rate them best to worst :) 1. Covergirl Lash Blast 2. Covergirl Clump Crusher 3. Maybelline Falsies 4. Maybelline Rocket Thank you so much!

- I've tried lots of mascaras from $5-$50. My 2 personal favorite are from loreal tarte. #1 Loreal- Telescopic Mascara (gold) #2 Tarte- lights, camera, flashes? statement mascara

- Q:if it would help you could say the fight is life or death. thanks

- how about #3 a gun

- Q:How does a lightning resistor work?

- There's nothing illegal about them cutting your pay, so no lawsuit there. And sorry, but if you were making $6 an hour more than average for your position, why wouldn't they cut your pay? The only chance you'd have for a case for a lawsuit is if you could prove you were let go because of your age. From your description, doesn't sound like you have a case there. If you resign, the only way you'd get unemployment is if you lie to the unemployment people and say you were fired, and the employer goes along with your story.

- Q:Is there company who makes, sells or has information about one. Or has plans on how to make one?

- My electrical teacher had a cool flourescent bulb crusher it was a 55 gallon drum w a motor mounter in lid shaft down with what looked like a lawnmower blade mounted under it off to the side of the lid was a small hole. turn on motor put bulb in hole instant crushed bulbs it was cool and safe. As the bulb went in the blade would spin so fast it busted whatever went in he built it himself. Just an idea.

- Q:what level of strength do i need to weild the dragon bone crusher on demons souls?

- 30. okorder /

- Q:an old grape crusher used in the early 1900's. winemaking.?

- OK

- Q:I want to purchase a carbon monoxide battery alarm with combination of fire or smoke or both. Do I need both a fire and smoke alarm or just one of them with the carbon monoxide?

- variety Rovers are no longer solid era. My pal owns a 2010 one and my neighbor owns the 2003 one. while making a sharp suitable turn, my neighbor's flipped over. As for my pal, 3 days while they offered their variety rover game, we went tocontinual up I-ninety on the cascade mountain variety. It broke down on the line interior the middle of the interstate.

- Q:ahahaha... that actually made me laugh. ... then again im high.

- 4/10 But you get a star because I've never heard it before.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Professional vsi crusher,sand making machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords