Professional Nail Clipper Custom Design Nail

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Professional Nail Clipper Custom Design Nail

Specification:

Item name | Professional Nail Clipper Custom Design Nail |

Item No. | CNBM003 |

Color | as your requested |

Size | |

Meas./Ctn. | |

| Weight/Ctn. | |

MOQ | 5000pcs |

Price Terms | FOB Tianjin |

Sample Time | 5days |

Port of Loading | Tianjin |

Payment Terms | T/T or L/C,Western Union |

Packing | 24pcs in a white box |

Shipment | By sea,by TNT,by air,UPS,DHL,Fedex etc. |

Company Name | CNBM |

Mission | Our profession ,your best choice,the best quality |

Products Brand | OEM |

Main Business | Glass nail file,nail buffer block,emery board,nail file & buffer, |

Customer's Feedback | High quality,Excellent service,The design always keep |

Why choose us:

We have/pass more Certification,

2. We have 16 Years of Silicone Production Experience.

3. we are direct manufacturer, high quality and competitive prices.

4. We also accept mixed order.

5. we accept OEM or ODM design.

Certification:

Quality control:

1) Forging test by DIGITAL MICROSCOPIC IMAGING TECHNOLOGY

2) Hardness test by TEMPER CHECKING MACHINE

3) Individual surface finish checking

4) Final inspection by DIGITAL MICROSCOPIC IMAGING TECHNOLOGY

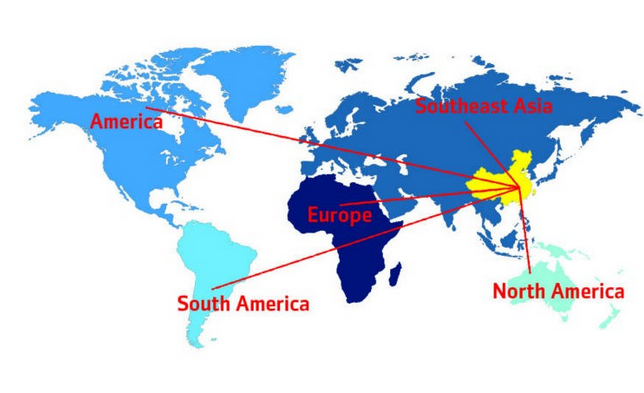

Market in the world:

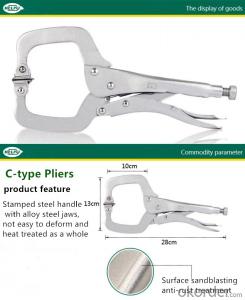

Key Features:

Brand new

Premium Grade Stainless Steel

Polished to High Standard Mirror finish

Fully guaranteed against defect in material and workmanship

- Q:440 steel knives do?

- 440 martensitic stainless steel, 440 is not a single imagine something, 440 tail number A, B, C, D, E, F, each tail number of the ingredients are not the same, only suitable for the production of 440C, commonly used tool, 440C was originally developed for the production of stainless steel knife, knife after America carpenter for handmade knives, steel Village carbon is about 1%, the chromium content of about 13%~18%, heat hardness of about 58. Now the domestic production of 440C steel, but there is a clear gap between China and foreign countries, such as the United States, Japan foreign plate plate plate is best, followed by South Korea, once again is Taiwan plate, and finally the domestic foreign plate, sheet of chromium was significantly higher than the domestic, the smoothness of the plate than the domestic high, domestic plate with gray point.

- Q:The difference between an ultrasonic knife, Germagi, and radio frequency

- Ultrasonic knife: 4.5mm probe directly acts on the deep layer of the muscle layer of the skin, precisely positioning, energy focused on one point, so that the muscle layer of the largest extent of the contraction. The 3.0mm probe focuses energy directly into the dermis 3.0mm, and there is no energy decay during the process.Germagi: when acting on the skin, the energy is transmitted through the epidermis to the deeper dermis, which is from the outside to the inside because it is heated in large areas rather than focused, so the energy is constantly attenuated during conduction.Radio frequency wrinkle is a probe to touch the skin, the radio wave energy transmitted to the skin deep. This deep balanced heating can promote the skin structure and subcutaneous tissue to stretch immediately, and there is no energy decay during the process.

- Q:What is the concrete structure of a shaver?

- The structure of an electric razor includes a cutter head, a motor, a battery, a plug, and the like. Electric shaver head structure comprises a knife net support ring, knife, knife blade assembly and network support, network and the knife blade assembly positioning with the buckle in each cutting knife net support ring and a knife net supporting frame is fixed between the bottom knife net support frame is connected with a universal joint are respectively arranged on the ring, ring a group of connecting shaft and a sliding groove group, connecting shaft and the knife net hinged on a supporting frame of a reversing hole with hinged sliding groove and is matched with the knife, under the knife head supporting bracket shrapnel.

- Q:What is the difference between a CNC lathe and a conventional knife?

- The machine tool is the blade, and the ordinary knife is grinding, relatively slow, and every time after sharpening, you must re - tool, the efficiency is very low

- Q:I used the pickup machine 630 of the machine, I would like to ask the knife head 30 degrees, 45 degrees and 60 degrees angle, what are the different differences and intentions?

- 30 degrees generally engraved relatively small words, sharp knife sharp, and the only defect life is relatively short compared to the other two;

- Q:What does the machining center do with the Kong Shi's empty cutter slot?

- The empty cutter groove is the cutter slot, which is mainly at the tail end of the blind hole and thread hole, in order to ensure the effective length and the processing time of the machined hole (screw hole)

- Q:Manual razors and razor compared to what kind of good?

- Manual razor and electric shaver have advantages and disadvantages, the It differs from man to man. manual, not easy to grasp, good angle and intensity, it is difficult to fit the facial contour, electric, the quality is not good to pull face pain, because it did not twist in the beard was cut

- Q:How about a ceramic knife?

- Easy to use: the proportion of ceramic material is about 2/3 of metal material, so it won't feel heavy like metal knife. It is very popular with modern women.

- Q:What is the scalpel made of?

- Now widely used 6CR13 cold-rolled martensitic stainless steel band, through the proper heat treatment, hardness of HRC 58, generally recommended cryogenic treatment, the effect is better.Of course, cheap also useful, 4CR13, 3CR13 stainless steel belt products, affordable.

- Q:On the hand sword thorn do

- This situation is caused by local friction and other reasons. Attention should be paid to the protection and care of the hands. Don't tear it so as not to cause infection. The barb long hands, hands often can be placed in warm olive oil (microwave) immersion, if not better, should supplement vitamin B6 or vitamin C. In addition, zinc can be used for half a month to see if it is effectiveThe barb finger skin is too dry, there are cracks in the cuticle, too long is not healing is a lack of vitamin C or vitamin B performance.The method is to deal with barb barb cut, soaked with olive oil and painted with hand cream. Or with fruit juice (such as apple, lemon, grapefruit) soaked in warm water for 10 to 15 minutes, nourishing the skin effect.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Professional Nail Clipper Custom Design Nail

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords