Professional cnc engraving machine for woods

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Syntec control system

2.9.0kw ai cooling spindle

3.Janpan Servo motor

4.Taiwan Hinwin rail

5.Vacuum table

Professional muti-function cnc engraving machine 1325

Main technical parameter

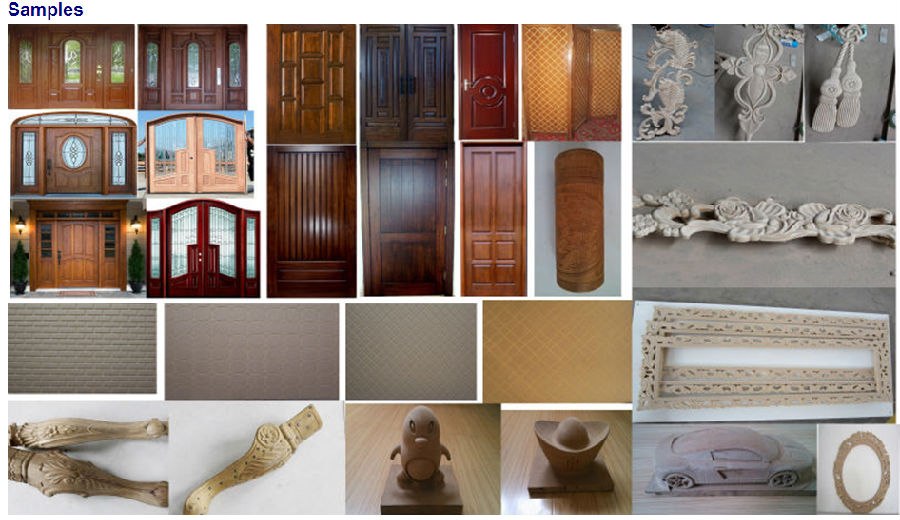

It can be used in carving on waved board, furniture door, arts door, paint free door, screen door and kinds of furniture.

Machine Size Work Envelope Repositioning Resolution Resolution Power Of Spindle Spindle Speed Max.Speed Max.Cutting Speed Bridge Clearance Control System Working Voltage Command Code | 2100×3500mm 1300×2500mm +0.02mm +0.001mm 9kw 0-18000(24000)rpm/Min 60000mm/Min 25000mm/Min 400mm SYNTEC control system AC380V/50Hz HPGL\G |

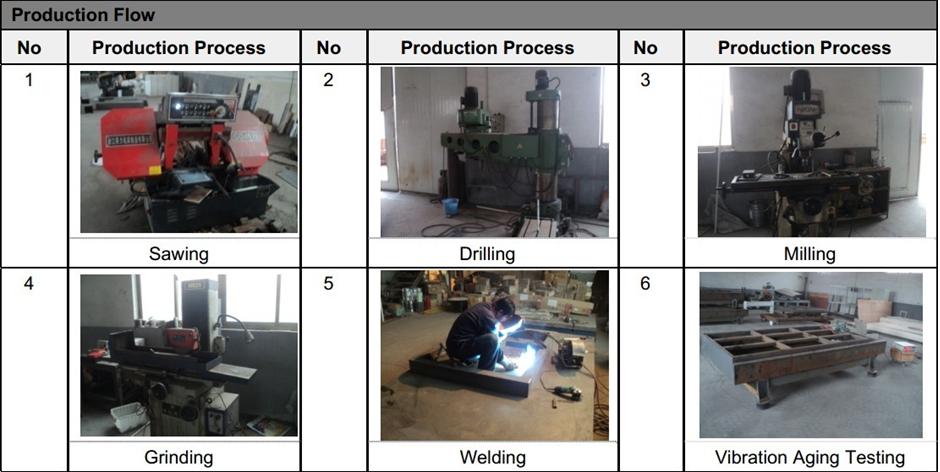

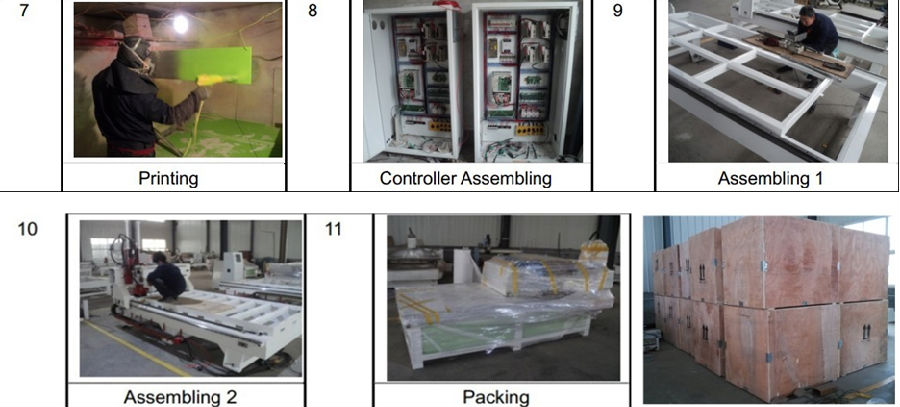

Machinery Characteristics:

Stable Structure: Square steel formed frame, stable and can not be deformed.

Perfect Parts: Imported Taiwan control system;AMT Line guide rail maid in Taiwan, due-row, four line ball slider, heavy loading and steady proceeding, German made ball lead screw with accurate cutting, Japan Servo Control system

Italy spindle motors.

l Good parts: The drive is more powerful: the use of well-known brands stepper motor,

become more powerful

l Armless automatic tool change system;magazine capacity 8(optional)

l High adhesion vacuum suction device;Displacement up to 230 cubic meters / hour

l Open software interface,.Excellent compatibility compatible of TYP3/ARTCAM/CASTMATE/WEITAI and other CAD/CAM design software Ensure that the design no problem.

- Q:Woodworking engraving machine can be milling dovetail groove?

- It is not easy to fix the workpiece, I suggest you do not use the engraving machine to mill, buy a bench was more than 1000.

- Q:What qualifications do you need to learn woodworking engraving machines?.

- First, wood carving, in general, the sculpture on the wood is usually overcast carving, and engraving machine depth requirements generally deep. In this way, the power is generally higher, and if the harder wood is encountered, it may make the engraving darker. If you want to make it lighter, increase the engraving speed and try to carve it several times. Some wood in the carving will produce some smoke, attached to the surface of the wood, if the wood has been painted brush, you can wipe it with a damp cloth, and if not painted may be wiped clean, resulting in surface fouling. Wood cutting. Woodworking engraving machine for cutting wood depth is not deep, the maximum power cutting depth depends on the wood materials and laser, such as cutting thick wood, cutting speed can be slowed, but may be caused by the burning of wood. Specific operation, you can try to use large lenses, and repeated cutting method. Two, logs (unprocessed wood) wood is by far the most commonly used laser processing materials, it is easy to engrave and cut. Light colored wood, such as birch, cherry, or maple, is easily vaporized by lasers and is therefore more suitable for carving. Each kind of wood label has its own characteristics, some are dense, such as hardwood, in engraving or cutting, you need to use more laser power. We recommend carving less familiar wood prior to studying engraving characteristics. Three, plywood in plywood engraving, in fact, in engraving, milling machine, wood carving is not very different, but there is a little attention, the engraving depth can not be too deep. The edges of the plywood after cutting will also be blackened like wood, the key is to see if plywood is made of that wood. Four, coloring more engraving machine engraving milling machine knowledge, please pay attention to Nanjing speed creation design

- Q:Which brand is good for woodworking engraving machine?

- The perfect service system is the carving machine manufacturer's development, the strong foundation. The establishment of a perfect service system is the urgent problem that many engraving machine manufacturers need to solve.

- Q:Woodworking engraving machine, the diagonal is not the same as how to adjust?

- The correct way is to loosen the screws on the Longmen according to the size of the error before and after walking machine and then tightly fixed screw die in Longmen so as to ensure that after the Longmen is not in the tilt (this method is only applicable to steel structure of Longmen aluminum plate Longmen) to loosen the slider and the gear box according to the size of the error before and after the transfer, if the screw is drive machine this problem you need to replace the nut, Longmen plate, screw machine is new if this problem was simply to return, this machine can not be used.

- Q:Woodworking engraving machine how much money?

- Engraving machines are not omnipotent. Carving machines are not capable of doing all kinds of work. Engraving machine manufacturers engraving machine is divided into various specifications, models, in order to deal with a variety of processing tasks. For example, you buy a mold level engraving machine to carve the swatches, or buy a large engraving machine to engrave the seals, which makes great waste, and won't get good results. Also, you buy an advertising engraving machine to make a mold, and you may not be able to do it at all. So before you purchase, you must show the sales staff clearly what you want to do, including the size of the workpiece, the material, the thickness of the material, the weight, the final engraving effect and requirements and so on.

- Q:General engraving function can not relief?

- You can use general relief carved software, Artcam software. As long as you learn how to make embossed software, you don't have to buy a cameo engraving machine. You can contact your purchase of the manufacturers, they certainly have matching software.

- Q:What's the cutter setting method of woodworking engraving machine?

- Try cutting knife:The table itself has a mechanical origin, you generally want to try cutting knife ah, like a knife after the car outside Z to exit, what is the measurement of the outer diameter of the car, and then find you with a knife, move the cursor to the X input X information... According to the measurement of the stage that the cutter tip position the diameter, as in the G screen, Z to be simple, put each knife in Z to touch a place and then measuring the Z0 on it.In this way, all the knives are recorded, and the machining zeros are determined in the workpiece movement (offshift), and any knife can determine the origin of the workpiece. This way, remember to read the knife before setting the knife.There is a more convenient way is to use the tool we know chuck, chuck diameter, tool diameter can touch input, the diameter can take a block with hand pressure on the same input in the chuck, chuck diameter can be.

- Q:Do woodworking carvings feature glass?

- The difference in the configuration of the different carved glass must be added a sink.

- Q:Is the single axle woodworking engraving machine powered by household power? The power is 2.5 to 3.2

- If a room is equipped with a 3-5P cabinet air conditioner, then this loop will be sufficient for your machine to use. And one of the most important questions: your machine, if you use three-phase electricity, is not available at home. Three phase alternating voltage 380 volts, household power is single-phase 220 volts.

- Q:Woodworking engraving machine and small CNC woodworking engraving machine prices?

- Pay attention to the manufacturers, I plant with 5 machines from 2013 to now, buy a few time ago because we do not understand, not too much attention to the machine that customer service, to use the time machine problems, customer service department timely how annoying manufacturers, therefore, suggest that you buy buy in engraving machine do not buy, or after the sudden death of your machine problems.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Professional cnc engraving machine for woods

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords