Professional cnc engraving machine High quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1

- Supply Capability:

- 30 /month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNC Router For Woodworking

1.1300 x 2500 x 200 mm

2.Air Cooled Spindle

3.CE Certificate & OEM supported

1.SPECIFICATION

WORKING AREA | 1300 X 2500 X 200mm |

SPINDLE POWER | 6KW,AIR COOLED,6000-24000RPM/MIN |

DRIVE SYSTEM | STEPPER MOTOR AND DRIVERS ON X,Y,Z AXIS |

WORKING SPEED | Y AXIS 25M/MIN, X AXIS 25M,Z AXIS 20M/MIN |

CONTROL SYSTEM | NC STUDIO NUMERICAL CNC SYSTEM (ENGLISH LANGUAGE);DSP PROGRAM |

WORKING VOLTAGE | 220V /380V |

TABLE | PVC MATERIAL WITH VACUUM SYSTEM |

OVERALL DIMENSION | 3900 X 2100 X 2100MM |

NET WEIGHT | 1200KGS |

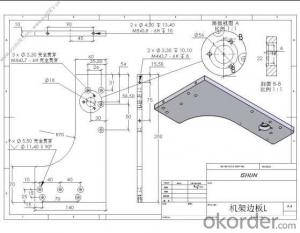

2. DETAIL PARTS INTRODUCTION

a). CONTROL CABINET BOARD

b). PRECISION RAIL GUIDE AND RACKS FOR TRANSMISSION (X&Y AXIS TRANSMISSION)

c). CONTROL CABINET d).OIL PUMPS FOR LUBRICATION

e). LEAD BALL SCRE (Z AXIS TRANSMISSION)

3. OTHER TERMS FOR MACHINERY

SINGLE PACKAGE: WOOD PALLET OR WOODEN CASE (OPTIONAL)

DELIVERY TIME: AFTER CONFIRMATION THE ORDER 35 DAYS

LOADING PORT: QINGDAO PORT, SHANDONG PROVINCE

- Q:What are the features of the spindle motor of the woodworking engraving machine?

- Spindle motor is an important component of computer engraving machine, and its performance has a crucial impact on the performance of computer engraving machine. Machining spindles are usually divided into two types: precision machined spindles and high power cut spindles.

- Q:Woodworking engraving machine, cutting tool, method of use

- Density board cut processing, recommended the use of double long chip spiral milling cutter, it has a chip, two high capacity planning has double-edged cutting function, very good, and very good balance to the tool, in the processing of high density board, not black, do not smoke cap, with long service life.

- Q:What should the frequency converter show when the woodworking engraving machine works?

- Three pause accelerationIn general, the parameters that run these settings are displayed.Wish you a happy life ~!

- Q:What are the main uses of woodworking engraving machines?

- Woodworking engraving machine is mainly used for wood processing, make it more beautiful value. Woodworking engraving machine of various types, many brands, which led to uneven prices.

- Q:What are the main points for copy classification in woodworking engraving machines?

- The radius compensation values at different depths are not the same at oblique machining or cone cutters, so small steps are easy to remain on the side. To avoid unsmooth sides, copy layering is available

- Q:Woodworking computer engraving machine, how to do the Dragon scales?

- The dragon carved software in the first Linyao in painting, coloring, stacking, sit path output, have a few processes

- Q:What's the voltage regulator for woodworking engraving machines?

- The actual power of your machine, engraving machine is the inductive load, in the actual work to overcome the power surge and inductive load (such as start impact, refrigerator, air conditioning, motor, motor etc.) instant starting current is 3 to 5 times the usual, enough to resist the impact of residual voltage, power will increase 3 5 times. 3, the brand's appeal, choose brand enterprises.

- Q:What are the engraving document formats of woodworking engraving machines?

- CNC CNC woodworking engraving machine users are mostly used for carving relief or flat drawing manufacturing. Regardless of what the customer is before use, CNC woodworking engraving machine, engraving machine must be painted the operation requirements of the document, and the document is operating way of CNC woodworking engraving machine, engraving picture is demand management files, and the pattern is nothing more than the bitmap and vector.

- Q:How to judge the temperature of the stepper motor of woodworking engraving machine overheating?

- The stepper motor is composed of an iron core and winding coils. The winding has a resistance, and when it is energized it produces a certain amount of heat. In fact, it is like a woodworking engraving machine spindle, the same motor, the temperature will continue to rise, but the spindle motor cooling water circulation to reduce the heat. But the stepper motor is no water cooling, then how to judge its temperature overheating question?.

- Q:What kind of wood do woodworking machines usually use?

- Camphor wood, texture staggered, delicate structure, smooth noodles, shiny, dry deformation after a small, durable, adhesive performance is good, easy to dye, rings are obvious, there are aromatic ignorant.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Professional cnc engraving machine High quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1

- Supply Capability:

- 30 /month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords