1600*900 laser engraver machine for sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Syntec control system

2.9.0kw ai cooling spindle

3.Janpan Servo motor

4.Taiwan Hinwin rail

5.Vacuum table

Professional muti-function cnc engraving machine 1325

Main technical parameter

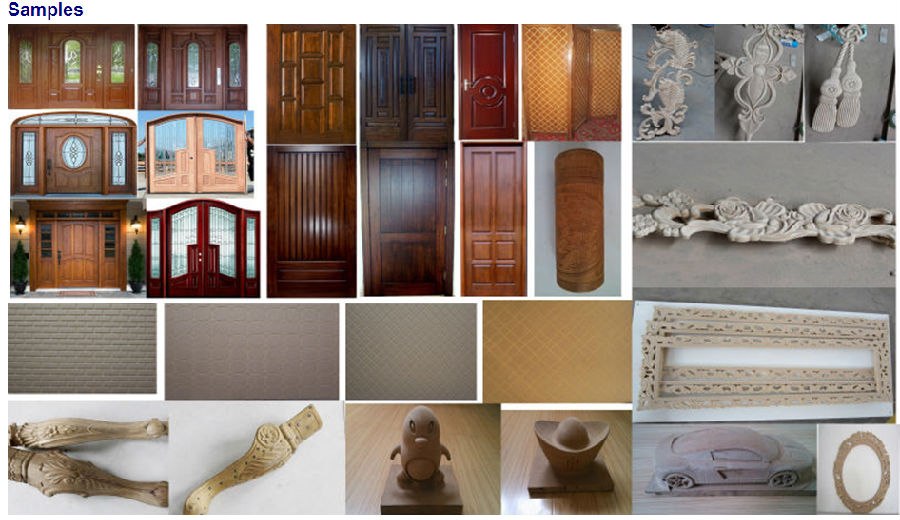

It can be used in carving on waved board, furniture door, arts door, paint free door, screen door and kinds of furniture.

Machine Size Work Envelope Repositioning Resolution Resolution Power Of Spindle Spindle Speed Max.Speed Max.Cutting Speed Bridge Clearance Control System Working Voltage Command Code | 2100×3500mm 1300×2500mm +0.02mm +0.001mm 9kw 0-18000(24000)rpm/Min 60000mm/Min 25000mm/Min 400mm SYNTEC control system AC380V/50Hz HPGL\G |

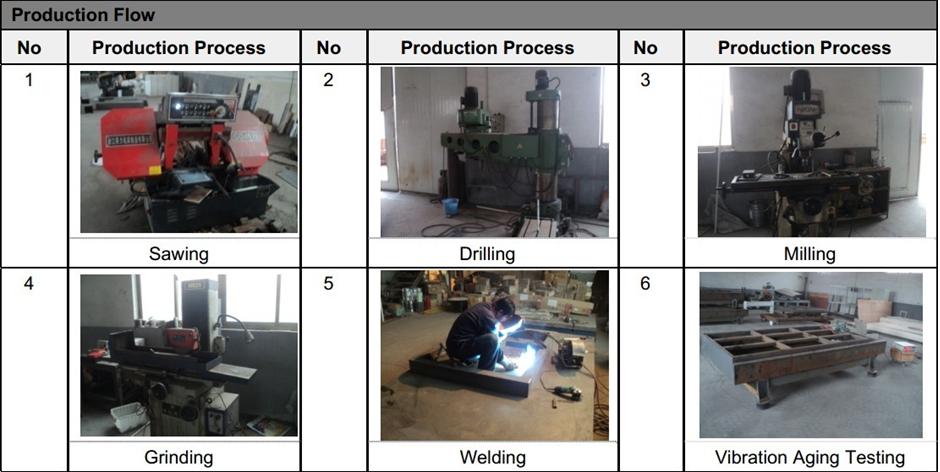

Machinery Characteristics:

Stable Structure: Square steel formed frame, stable and can not be deformed.

Perfect Parts: Imported Taiwan control system;AMT Line guide rail maid in Taiwan, due-row, four line ball slider, heavy loading and steady proceeding, German made ball lead screw with accurate cutting, Japan Servo Control system

Italy spindle motors.

l Good parts: The drive is more powerful: the use of well-known brands stepper motor,

become more powerful

l Armless automatic tool change system;magazine capacity 8(optional)

l High adhesion vacuum suction device;Displacement up to 230 cubic meters / hour

l Open software interface,.Excellent compatibility compatible of TYP3/ARTCAM/CASTMATE/WEITAI and other CAD/CAM design software Ensure that the design no problem.

- Q:What specifications of linear guide rail are used in woodworking engraving machines?

- Engraving machine on the guide rail, according to its cross section on the width of the division, of course, the wider the greater the weight of support, the general use of 20mm and 25mm.

- Q:Woodworking engraving machine work, the main axis of the continuous downward, what is the reason?

- If you can not see the obvious dislocation of the knife mark, you can control the Z's drive to try with other changes, if there are obvious scratch marks, there may be a lot of reasons

- Q:Woodworking engraving machine to determine the depth?

- The tool strength limit: if cutting tools in the feed rate is too large, increasing the tool stress will accelerate tool wear, reduce the processing efficiency.

- Q:Woodworking engraving machine how to use the tool can not be hurt to the table?

- Then, according to the cutting depth set in the Thai region, the corresponding height is raised. Here, let the Z axis be zero again. This is the origin of the Z axis. According to the setting depth in the Thai Thai, engraving machine down to the lowest point is my family once a zero place, just on the top of the table, so that the material is fully engraved, and will not hurt the engraving machine table.

- Q:Woodworking engraving machine processing plane appear jagged

- Another possibility is that the slider of your machine is broken

- Q:Woodworking engraving function can not be framed?

- 2.2KW high-power water-cooled inverter constant power motor, the overall casting body, "strong physique, steel special.""

- Q:What kind of woodworking engraving machine is suitable for small and medium-sized panel furniture processing plants?

- Recently, the opening software on the market is also very convenient to use. NC cutting software, very easy to learn, the input size, number of automatic layout optimization, and can directly generate the path of engraving engraving machine can be used, greatly saves the labor cost, reduce waste generation. 1325 woodworking engraving machine with automatic opening software, is a small and medium-sized panel furniture processing plant a good choice.

- Q:How to operate the woodworking engraving machine can make the engraving process more simple and convenient?

- First, the first mode of operation for computer control, this control method is most welcomed by customers, which is popular with young people, the computer knowledge level is not high, and easy to learn, computer operation more intuitive, and computer operation can show some problems of the carving and engraving, and this time. The system can be compatible in the operation of the system, but also can do some other things with a computer.

- Q:Woodworking engraving machine, how to engrave the double curved arc?

- There's no other way to break it!

- Q:How to distinguish woodworking engraving machine, river advertising engraving machine?

- The traditional screw drive as the transmission mode, this is also the processing of advertising materials mostly relatively soft features. In the mechanical design aspect, the engraving machine drives the way to make the difference adjustment, this is because of both work content difference causes. Rack drive mode, large, fast, consistent with the requirements of woodworking engraving accuracy, this requirement is not high, nor strict, but the speed requirements are fast enough, the knife depth is enough. However, because there is a gap between the gears, the engraving machine has a lower precision, but it also meets the requirements of woodworking and processing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1600*900 laser engraver machine for sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches