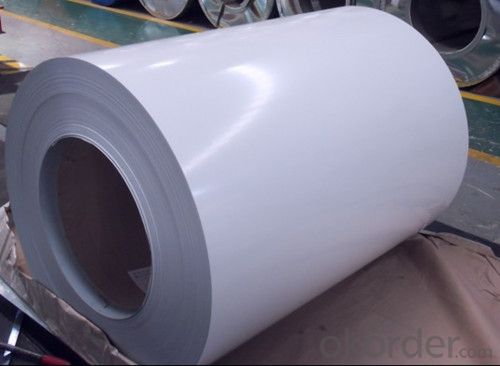

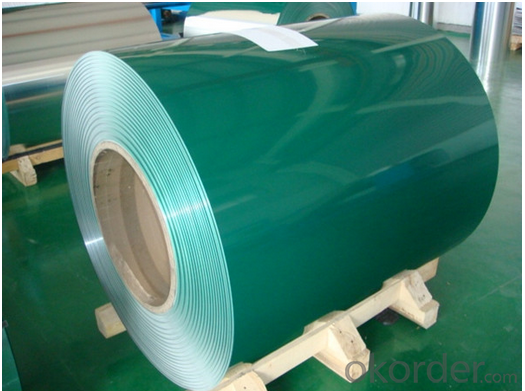

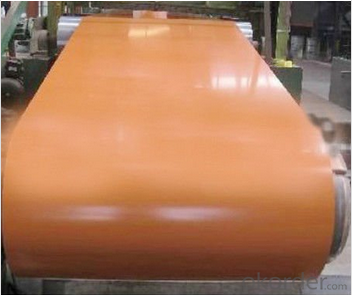

PPGI Metal Building Materials /Pre-painted Hot Dipped Galvanized Steel Coil/Aluminized

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.PPGI Metal Building Materials Features:

. A strong anti-corrosion properties, good corrosion resistance. The use of hot dipped galvanized steel substrates for the Color Painted steel coil, with the exception of zinc have anti-corrosion layer, a layer of coatings have seized coverage and protection, allowing effective anti-rust products, galvanized coil about life than double.

. A good cold-formed molding processing, users can directly processed into finished products. Substituting wood to steel, easy to transport, and efficient construction, energy conservation.

2.Applications of PPGI Metal Building Materials

* Used as roof panel, wall panel in steel structure in warehouse,

factories exhibition hall container houses, cold storage

*It is also mainly used in light industry, automobile, construction,

animal husbandry, fishery and commerce, etc,

3.Product information:

| PRODUCT | PPGI Metal Building Materials |

| STANDARD | GB/T-12754: 2006, JIS330, ASTM A653, JIS G330, GB/T2518, ASTM A792, JIS G3321, JIS G3317 |

| BASE METAL | Hot dipped Galvanized steel sheet/coil, Hot dipped Galvalume steel sheet/coil |

| EQUIPMENT | Double coating double baking; three coating three painting |

| SUPPLY CAPACITY | 500,000 Tons per Year |

| SIZE | Thickness: 0.3mm-1.0 mm,thickness tolerance: +/- 0.02mm Width : 700mm—1250mm |

| ZINC COATING | 30g/m2-150g/m2 |

| PAINT THICKNESS | Top Side: 10-25 microns; Back Side: 4-8 microns |

| COIL WGT | Normally 5 Tons per Coil, aslo as required by customer |

| COIL ID | 508mm/610mm |

| SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

4.PPGI Metal Building Materials image:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:Cast steel welding

- I Use these for cast iron, www.yms .uk/welding-rod-small-pack/2.5mm-cast-iron-welding-rod-small-pack/1951/11612/detail.asp they are expensive when compared to welding rods for steel but i find that normal steel ones dont work on cast iron

- Q:Hey guys do you know anything about Steel Arch Building and how this structure really looks like?

- Just google steel arch building, you will get plenty of selection , pictures, prices and designs

- Q:How do steel coil manufacturers ensure employee safety?

- Steel coil manufacturers ensure employee safety through a combination of safety training programs, implementation of safety procedures and protocols, regular equipment maintenance, and providing personal protective equipment. They also conduct regular safety audits and inspections to identify and address any potential hazards in the workplace.

- Q:How long can steel coils be stored before they need to be used?

- Steel coils can typically be stored for an extended period of time, ranging from a few months to several years, depending on various factors such as the coating, storage conditions, and the type of steel. However, it is generally recommended to use or sell steel coils within a year or two to ensure their optimal quality and performance.

- Q:Several reading methods of steel tape measure

- Direct reading method when measuring the steel tape zero scale alignment measurement starting point, proper tension (stretching force with steel tape tension or tension on the calibration ruler identification shall prevail, with the spring balance measure), direct reading measurement end point corresponding to the scale scale.

- Q:How are steel coils used in the manufacturing of automotive body panels?

- Steel coils are used in the manufacturing of automotive body panels because they provide a strong and durable material that can be easily shaped and formed into the desired panel shapes. The coils are unwound and fed into a stamping press where they are cut, shaped, and molded into the specific body panel design. This process ensures that the panels have the necessary strength and structural integrity required for automotive applications.

- Q:What is the maximum diameter of a steel coil?

- The maximum diameter of a steel coil varies depending on the specific type and thickness of the steel, as well as the capabilities of the manufacturer's equipment. However, in general, steel coils can have diameters ranging from a few inches to several feet.

- Q:What are the different types of steel coil finishing processes?

- There are several types of steel coil finishing processes, including hot rolling, cold rolling, galvanizing, and coating. Hot rolling involves passing the steel through high temperatures to shape and form it. Cold rolling is a similar process but is done at lower temperatures to improve the steel's surface finish and dimensional accuracy. Galvanizing is a process where a layer of zinc is applied to the steel to protect it from corrosion. Coating processes involve applying a layer of paint or other protective substances to enhance the steel's durability and aesthetics.

- Q:How are steel coils used in the production of appliances?

- Steel coils are used in the production of appliances as a primary material for constructing the various components, such as the outer shells, frames, and internal structures. The coils are processed and shaped into specific sizes and forms to meet the requirements of different appliances. Additionally, steel coils provide strength, durability, and a sleek appearance to the finished appliances.

- Q:How are steel coils processed for galvanizing or coating?

- Steel coils are processed for galvanizing or coating through a series of steps. Firstly, the coils undergo surface preparation, which involves cleaning, degreasing, and removing any rust or mill scale. This is done using chemicals, mechanical methods, or both. Next, the coils are immersed in a zinc bath for galvanizing or passed through a coating application process for other types of coatings. This ensures a uniform and protective layer on the steel surface. Finally, the coated coils are cured or dried using heat or air, after which they are ready for further processing or shipment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PPGI Metal Building Materials /Pre-painted Hot Dipped Galvanized Steel Coil/Aluminized

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords