Petroleum Chemical Pump with API 610 Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

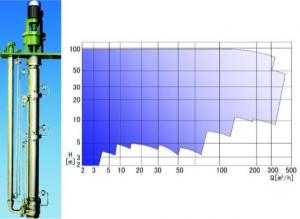

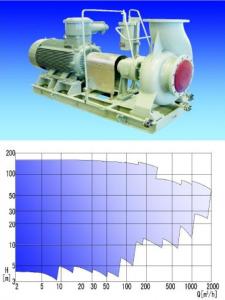

performance range of api 610 pump/ chemical pump/ petro oil pump

Flow Range: 25~8000m3/h

Head Range:60 ~ 1600m

Fluid Temp.:Up to 260℃

Viscosity:Up to 800 mm2/s

1. Quality guaranteed. It has API610 (8th Edition) standard design and certified by ISO9001.

2. Easy operating. With both suction inlet and discharge outlet located in pump casing, it has no need to disturb the piping and motor when maintaining and serving the internal parts, even no need to open the pump cover when replacing mechanical seals and bearings.

3. Safe. Twin volute design and opposed symmetric impeller arrangement combined to obtain perfect radial and axial balances under all operation conditions. Double suction impellers plus inducers may also be utilized for reduction of cavitations.

4. Flexible. Pump shaft, with computer optimized design, keyed with the impellers symmetrically arranged on the shaft, rotor assembly strictly checked with computer program to ensure controlled radial flexibility and dynamic balance,.

5. Advanced leak-proof technology. Advanced hydraulic model engenders compact construction with spacious internal passageway efficient for crude oil of high viscosity. The high-strength bolts, computer optimized designed, connect upper and lower casings together and ensure a leak-less operation at super pressure conditions.

6. Heat resisting. Shaft sealed with high pressure mechanical seals that are forcibly cooled and rinsed with solution treated through vortex separations, which makes it applicable for pumping of high temperature liquids and crude oil, besides the mechanical seals are located at the low pressure area far away from the center where the high pressure zone lies.

7. Bearing and coupling systems are designed for heavy duty and high speed operation. The SKF centripetal thrust bearing plus self-lubricating or forcibly lubricated slide bearing shall balance the remnant axial force. Air and water cooling are available for slide bearings, elastic bolts coupling and membranes plus intermediate coupling selectable.

8. Pump temperature, vibration and leakage are monitored and alarmed both locally and remotely. Automatically control of the pump could be realized through connection with customer’s auto systems.

- Q:How to change the oil pump 1.8 MAGOTAN

- Hello! The best to replace the 4S shop, if the warranty period, can request a free replacement

- Q:How does the c4l determine whether the oil pump works? The oil lamp is on

- The oil pump is basically mechanical, so you can try changing the oil sensor.

- Q:110 engine oil pump gear is always broken, what should I do?

- Like to change a good, do not like

- Q:Why does the engine oil pump need good timing?

- No need for oil pump

- Q:4Y engine oil pump, okay? Still lifting the engine?

- Hello, you don't have to carry it down. You can change it on it, but it's very troublesome!

- Q:Is it not the oil pump with the wrong oil hole Doutong.

- The oil tank should be emptied into the air at the rear of the oil pump.

- Q:474 new engine replacement and pump axle

- That's the rough line. You need to grind the shaft

- Q:Will it clog up the oil pump by cleaning the engine oil which is strong enough to clog up the oil circuit?

- If the engine is too much carbon deposits, the use of such properties of oil, it is true that such a situation can occur. The first is blocked by the oil pump filter. The oil passages are not blocked, because carbon deposits are filtered first by the filter. Sludge is capable of entering the oil passages.

- Q:Santana pump engine sound big bad

- The oil pump is broken, and it is easy to damage the engine because of bad lubrication!

- Q:What is the function of the oil pump?

- The oil pump is used to press the oil in the oil pan to the filter, and the engine oil can still be reliably conveyed to the friction surfaces of each lubricating oil passage and the moving parts after the filter is passed. When the engine is working, the oil pump keeps working to keep the oil circulating in the oil circuit. If damaged, there may be noise, noise, power attenuation, if not in time, even the cylinder can not start, the engine completely scrapped!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Petroleum Chemical Pump with API 610 Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords