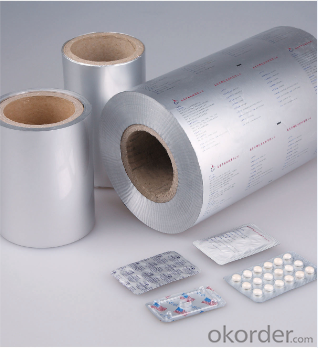

PE/PET Aluminum Foil Induction Seal Liner for Pesticides Bottle Sealing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product name: Induction seal liner for plastic and glass bottles

1. Introduction

Induction lining materials are one of the most important parts in packing industry for sealing the bottles and containers of the products for many reasons. And induction sealing is a simple and reliable method of bottle sealing. It welds an aluminum foil seal across the bottle neck.

2. Main specifications:

- Aluminum foil = 20-40 microns (0.02 - 0.03 mm)

- PE/PET/PP layer = 40-50 microns (0.04 - 0.05 mm)

- Seal backing material: pulp, foam, cardboard;

- Easy peel and non-easy peel seal available;

- Seal diameters are available from 10 mmto 180 mm;

- With different composition, liner thickness is various from 0.2mm to 1.2mm;

- It can be printed with custom logo, or embossed with any desired design;

3. Main benefits:

- Seals in freshness

- Prevent costly leaks

- Reduce the risk of tampering, pilferage, and contamination

- Extend shelf life

- Create hermetic seals

- Environment friendly

4. They can be used for sealing & packing in the different industries, including:

1- Motor, Engine, and Lubricant Oil products

2- Edible Oil products

3- Medicine products (Pharmaceutical factories for Tablet, Gel, Cream, Powders, Liquids, etc)

4- Food Products

5- Beverages, Fruit Juice, Butter, Honey, Mineral Water

6- Pesticides, Fertilizers, and Chemicals

7- Cosmetics

5. How to use:

Induction lining materials are constructed from aluminum foil membranes, coated with polymer and attached to a backing material by means of wax or polymer bond. This foil laminate is then placed inside a cap or closure, and the closure applied to the container, bringing the foil laminate into contact with mouth of the container.

The container then passes underneath the induction sealing head, where an electromagnetic field creates a low level of localized heat on the foil membrane, which is sufficient to melt both wax bond and polymer coating.

Soon after the container leaves area of the electromagnetic field, the polymer hardens, forming a flexible, yet hermetic seal between foil and neck of the container, while the backing material goes inside the cap as interior liner for more protection

6. Other information: heat induction foil liners

Name | bottle cap liner | MOQ | 100000 pieces |

Usage | This bottle cap liner is widely used in Pesticides, oil, chemical, food, medicine and other fields | Printing | 1-6 colorsprinting |

Specification | Thickness:0.1-0.3mm | ||

Shape | Round | ||

Features |

| ||

Application | bottle cap liner Is suitable for PVC,PET,PE,PP,PS ,PA,ABS ETC plastic bottles and glass bottles | ||

Min order: | 100000 pieces | ||

7. Why Choose Induction Sealing?

When properly applied, induction lined caps provide a hermetic, leak proof, and tamper evident seal. Using an induction sealing system is ideal for extending product shelf life, preserving freshness, preventing costly leaks and enhancing your product's value.

8. In order to quote you an accurate price, please kindly inform us the following information:

1.The diameter?

2.The thickness?

3.Whether printing? How many colors to be printed?

4.The material of the bottle, PE/PP/PVC/PS/GLASS or others?

5.The quantity you need?

- Q:Characteristics of anodized aluminium plate

- (5) strong pollution resistance: no fingerprints, but also traces of dirt, easy to clean, no corrosion spots.(6) applicability: it is widely used in metal aluminum ceiling, curtain wall, aluminum plate, aluminum plastic panel, fireproof board, honeycomb aluminum plate, aluminum veneer, electrical panel, cabinet panel, furniture panel, etc..

- Q:i want to build a smelter to recycle aluminum auto parts

- Tita, while providing an elegant answer, forgot to mention that it is mostly cut and paste from Wikipedia. I'll provide the link for her below. She also forgot to copy and paste the part about aluminum oxidizing easily when it is heated and melted. If you are trying to smelter aluminum, you will need to have a compressed or dense mass of aluminum and a smelter that is airtight. Otherwise, it will just oxidize right back into aluminum oxide, which is a white powder. You've probably seen this when you throw a beer can in the campfire? good luck and have fun in your endeavors. And always remember to cite your source!

- Q:A construction worker uses a steel tape to measure the length of an aluminum support column. If the measured length is 17.7 m when the temperature is 21.2°C, what is the measured length when the temperature rises to 35.4°C? (Note: Do not neglect the expansion of the steel tape. Give your answer to three decimal places.)I am really confused... Could someone solve it for me with a step-by-step explanation? Thank you so much.

- Assume linear thermal expansion with constant expansion coefficient. The change of length is given by: ΔL = L?·α·ΔT (L? initial length, α linear thermal expansion coefficient) The overall length of an object as function of temperature is: L= L? + ΔL = (1 + α·ΔT) · L? Consider the measurement at 21.2°C as reference: The aluminum column changes its length to L= (1 + α_aluminum · ΔT) · L? = (1 + 23×10-6 ^C°-1 · (35.4°C - 21.2°C) ) · 17.7m = 17.705m That would be the length measured with a steel tape at reference temperature of 21.2°C. Unfortunately the steel tape expands too. Because the scale increases with the expansion it measures too short. On the expanded tape you read the length L? while the actual length is L. Hence the measured length is: L? = L / (1 + α_steel · ΔT) = 17.705m / (1 + 11×10-6 ^C°-1 · (35.4°C - 21.2°C) ) = 17.003m

- Q:I am trying to find away of turning aluminum oxide or alumina into just aluminum. Please post all ideas i dont care how crazy.

- The problem is that in an oxygen rich environment, like the air, then aluminum will instantly form a protective coating of aluminum oxide on any freshly prepared surface. So, mechanical sanding or abrasion will be of little help. You could abrade the surface inside of a container where there is no oxygen. That would require the construction of an airtight glovebox, then fill it with N2 or an inert gas. The aluminum oxide coating will dissolve in very basic solutions. Aluminum metal is also very reactive with water. 2Al + 6H2O -- 2Al(OH)3(s) + 3H2(g) In Drano, the basic solution dissolves the Al2O3 coating, which allows the Al metal to react with water producing H2 gas and the agitation needed to help dissolve the clog.

- Q:What are the common applications of aluminum sheets?

- Aluminum sheets are commonly used in various applications such as construction, automotive, aerospace, packaging, and electrical industries. They are used for making lightweight structures, including building facades, roofing, and cladding. In the automotive sector, aluminum sheets are used for manufacturing vehicle bodies and parts due to their high strength-to-weight ratio. They are also utilized in aircraft manufacturing for their low density and corrosion resistance. Additionally, aluminum sheets are popular in packaging as they are lightweight and can be easily formed into different shapes. In the electrical industry, they are used for wiring and conductors due to their excellent conductivity properties.

- Q:Why must the aluminum oxide be electrolyzed in a molten cryolite solution?

- To electrolyse aluminium oxide, it has to be molten. However, the melting point of Al2O3 is extremely high ( 1000°C), and that would make the electrolysis very inefficient. However, Al2O3 dissolves in cryolite at much lower temperatures (lower than 900°C), which makes it a much more viable process.

- Q:Can the aluminum sheets be used for manufacturing food storage containers?

- Indeed, food storage containers can be manufactured using aluminum sheets. The utilization of aluminum in food storage containers is widespread due to its qualities such as being lightweight, long-lasting, and possessing exceptional thermal conductivity. Its malleability allows for effortless shaping into diverse dimensions, making it adaptable for various storage requirements. Moreover, aluminum exhibits resistance to corrosion and can be conveniently cleansed, guaranteeing the protection and cleanliness of the stored food.

- Q:What are the different surface treatments available for aluminum sheet?

- There are several surface treatments available for aluminum sheet, including anodizing, powder coating, painting, and polishing. Anodizing provides a durable and corrosion-resistant finish, while powder coating offers a wide range of colors and enhanced durability. Painting allows for customization with various finishes and colors, while polishing provides a shiny and reflective surface. Each treatment option offers different aesthetic and functional benefits, depending on the specific requirements and desired outcome.

- Q:Can aluminum sheets be used for decorative or architectural purposes?

- Yes, aluminum sheets can be used for decorative or architectural purposes. Aluminum is a versatile material that can be easily manipulated into different shapes and forms, making it ideal for various architectural applications. It is commonly used for exterior cladding, roofing, window frames, and facades, providing a sleek and modern aesthetic to buildings. Aluminum sheets can also be used for decorative purposes, such as wall panels, art installations, signage, and furniture. The lightweight and durable nature of aluminum make it a popular choice for architects and designers looking to create visually appealing and functional structures. Additionally, aluminum is resistant to corrosion, making it suitable for both indoor and outdoor applications.

- Q:Can aluminum sheets be used for architectural cladding?

- Yes, aluminum sheets can be used for architectural cladding. Aluminum is a popular choice for cladding due to its durability, lightweight nature, and resistance to corrosion. It is commonly used in both residential and commercial buildings for its aesthetic appeal and versatility in various architectural designs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PE/PET Aluminum Foil Induction Seal Liner for Pesticides Bottle Sealing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords