New Products for Olive - Falling Fruit Harvesting Nets 50GSM

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

New Products for Olive - Falling Fruit Harvesting Nets 50GSM

Production Description:

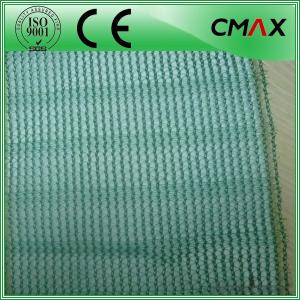

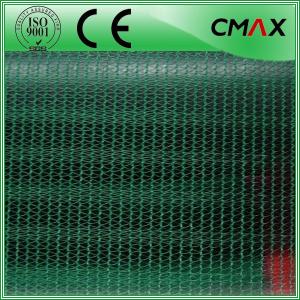

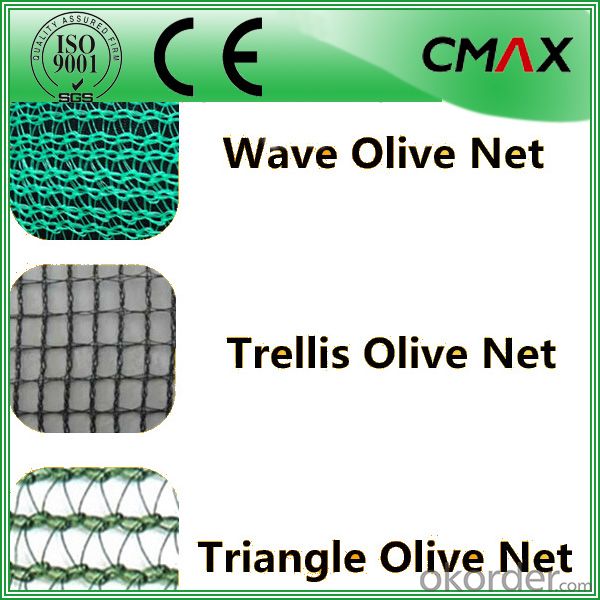

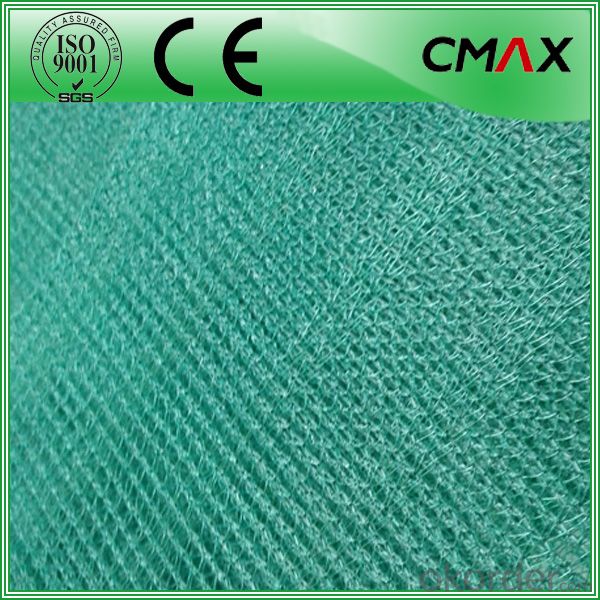

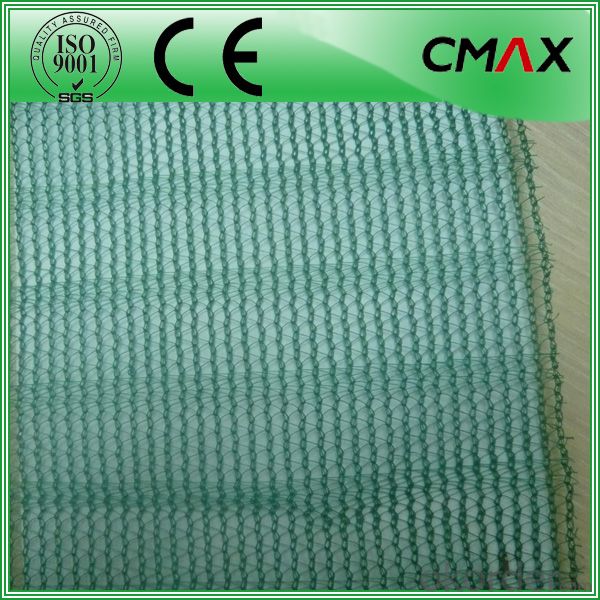

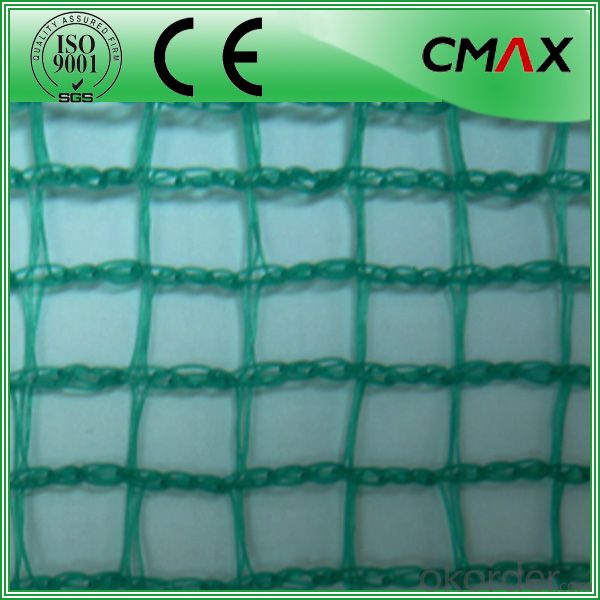

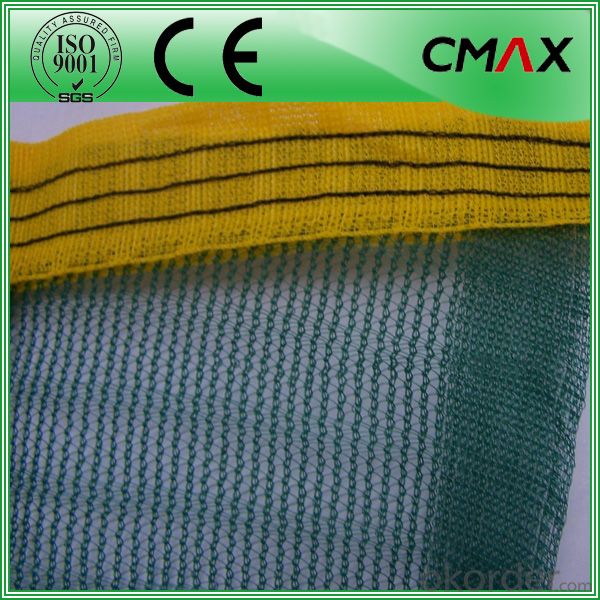

These nets are entirely made of UV stabilised polyethylene monofilament. The nets available have various kind of meshes in order to optimise the different harvesting methods of olives and fruits. Every net is suitable for a different application such as natural falling harvesting, hand harvesting or mechanised harvesting. The nets are available in different weights and colours and can be supplied in rolls or in sheets already stitched together with or without central vent.Olive collection net are used not only for the olive harvest, but also to gather chestnuts, nuts and deciduous fruits in general.

Produced with HDPE virgin material

UV stabilized - Long life

For Food : non-toxic, responsive to current European legislation on packaging for food.

Guarantee 5 years

Green&Black 50g/m2

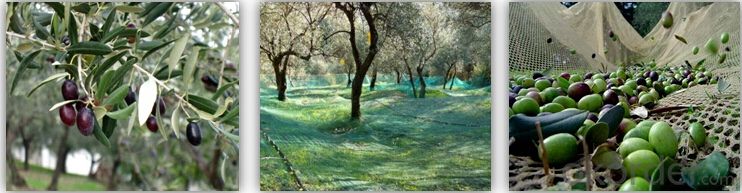

Farmer used the net to gain olive from tree.

Specification:

| Type | CMAX-Olive Net |

| Weight | 33-200 gsm |

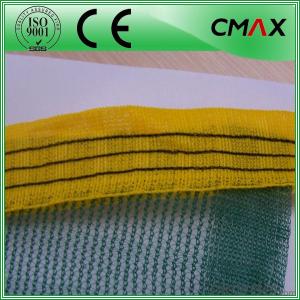

| Color | Black, Green, Dark Green, etc |

| Width,Length | 1-6m, 50m,100m as your requirements |

| Raw material | 100% Virgin HDPE with U.V Stabilized and irganox |

| Using life | At least 4 years |

| Delivery time | 30 days after deposit |

| Specification | construction(/inch) Warp=3, Weft=4.5, Br.Str.(kg) ,Warp=10, Weft=2 ,Screening factor(%) :10% |

| Packing | rolls with PVC suare tube(5×5cm)/double folded/PE Stretch film/label |

| OEM | If you have your own packing design,we can quickly meet your requirments. |

Application:

Process:

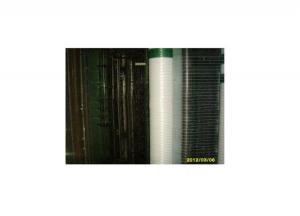

Shipping&Packing:

Delivery Time: 20 Working Days After Confirmed P.O.

Packaging: Each piece packed in plastic bag, and several pieces per bale with PP woven bag outside, or in rolls with inner paper tube with plastic bag outside.

FAQ:

1.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Shanghai, China. You can take flight to Shanghai Hongqiao airport, and 25 mins reach to our factory.

2.Q:What is the material of your products?

A: We use the raw material of High Density Polyethylene (HDPE) with UV Stabilized & Igranox to make our netting

3.Q:How does your factory do regarding quality control?

A: we are very proud to let you know that , We use the best raw material , have at least 5years experienced workers,

the advanced machine and specialized team to assure the quality

We perform Quality Control inspections on 100% of our products.

Our inspection standards are strictly in accordance with the ISO9001 certification system.

- Q:How often should ground cover plants be watered?

- Ground cover plants should generally be watered about once or twice a week, depending on the specific plant and environmental conditions. It is important to monitor the soil moisture and water accordingly, ensuring it is consistently moist but not overly saturated.

- Q:Are there different sizes of nursery trays available?

- Yes, there are different sizes of nursery trays available.

- Q:If you say plastic, can you tell me what it's made from? Did you know some of the resins from trees is made into plastics and alot of other products we use daily, not just toilet paper? Or tell me how clean a plastic factory is compared to a sawmill? Or do you think plastic products just grow naturally?

- Plastics are made principally from petroleum products. There are some botique plastics that are produced for the hemp-wearing set using non-petroleum based hydrocarbons, but the resins don't stand up to stress over time. Wood is renewable. 'nuff said.

- Q:Do nursery trays come with a humidity control feature?

- No, nursery trays typically do not come with a humidity control feature.

- Q:Are nursery trays suitable for urban gardening?

- Yes, nursery trays are suitable for urban gardening. They are compact, lightweight, and can easily be placed in small spaces like balconies, rooftops, or windowsills. Nursery trays also provide a controlled environment for seed germination and young plant growth, making them ideal for starting a garden in an urban setting.

- Q:This is the most depressing article I've read in awhile. What is preventing us from recycling a larger volume of plastic? Is it not cost effective? Is that whats holding us back?

- in most cases plastic can only be reused about 3-4 times before the company has to trash the material unlike aluminum cans which can be used again and again :o) it's such a shame that people can just ruin the ocean with all of our trash... isn't it bad enough that we're chasing animals off land to make new urban areas and houses but now we're actually chasing animals out of the ocean too! it's so sad... I think once school starts again, I'm going to do a postsecret idea and put that pic of the turtle on a note card that says please Recycle need to all of our vending machines on campus... it may not be much but if 1 person does recycle then it'll be worth it :o)

- Q:Is there a type of bassoon that has both plastic and wood joints?

- Worlds okorder

- Q:What are the main manufacturers of agricultural plastic products?

- Some of the main manufacturers of agricultural plastic products include Berry Global Inc., DowDuPont Inc., Novamont S.p.A, Raven Industries, Inc., and Armando Alvarez Group.

- Q:For some odd reason, I will catch my cat trying to eat plastic wrap. There were times where I had to force his mouth open, reach in and pull it out before he swallowed it. Why is he doing this? He has fresh food and fresh water everyday.

- Idk why but it's not at all good for him!

- Q:plastic around bathtub has plastic pipe cleaner spilled on it. how do you clean it off.

- I'm afraid it may have 'melted' into the plastic. Try some alcohol. Next, try something like 'goo-be-gone'. Lastly, get some clear pipe cleaner/solvent and use that. Good luck!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

New Products for Olive - Falling Fruit Harvesting Nets 50GSM

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords