Mill Finish Five Bar Aluminium Treadplates 5052 HO for Boat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Mill Finish Five Bar Aluminium Treadplates 5052 HO for Boat

1.Structure of Mill Finish Five Bar Aluminium Treadplates 5052 HO for Boat

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Mill Finish Five Bar Aluminium Treadplates 5052 HO for Boat

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

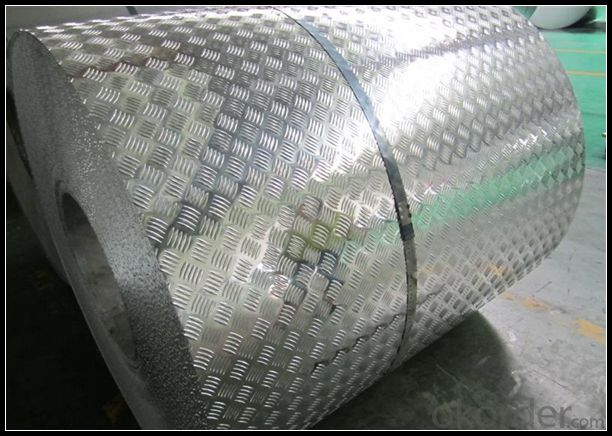

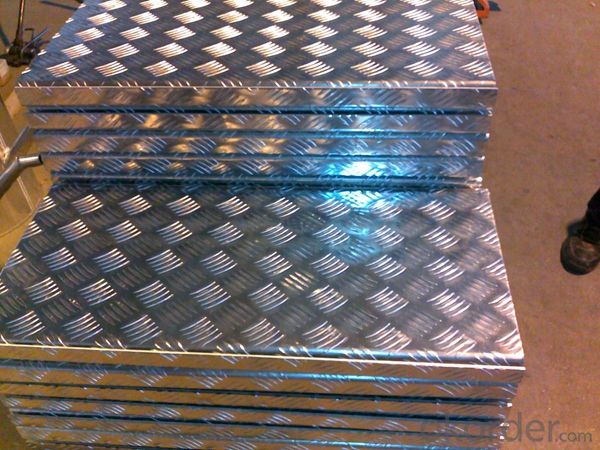

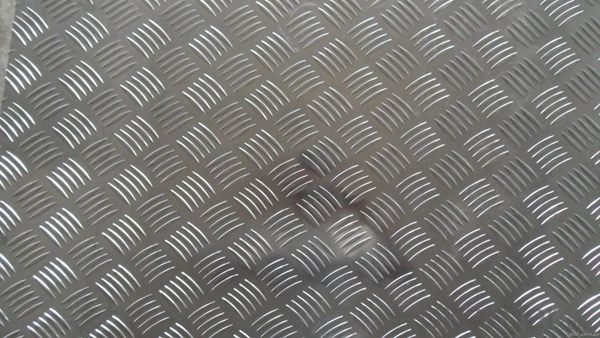

3. Mill Finish Five Bar Aluminium Treadplates 5052 HO for Boat Images

4.Specification of Mill Finish Five Bar Aluminium Tread Plates 5052 HO for Boat

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ of Mill Finish Five Bar Aluminium Treadplates 5052 HO for Boat

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:What's the difference between laser cutting aluminum plate and stainless steel plate?

- The absorptivity of aluminum plate and stainless steel plate to laser is different. The aluminum plate is more reflective and easier to be removed during cutting

- Q:Aluminum plate thickness 3 mm, what is the allowable error in the national standard thickness?

- The allowable deviation of plate thickness in GB/T3880.3-2006 "general industrial aluminum plate, strip and Aluminum Alloy third part:" size deviation provisions, I have the standard download URL sent to you a message, please check.The deviation is divided into ordinary and high level, +0.10, -0.12

- Q:Can aluminum sheets be laminated?

- Yes, aluminum sheets can be laminated. Lamination is a process of bonding multiple layers together to create a composite material with enhanced properties. In the case of aluminum sheets, they can be laminated with other materials such as plastics, adhesives, or even other metals. This process can improve the strength, durability, and thermal or electrical conductivity of the aluminum sheets. Laminated aluminum sheets are commonly used in various industries, including construction, automotive, aerospace, and packaging, where the combination of different materials provides the desired characteristics for specific applications.

- Q:What are the different types of surface treatments available for marine-grade aluminum sheets?

- There is a variety of surface treatments available for marine-grade aluminum sheets, each with unique benefits and characteristics suitable for different applications. 1. Anodizing: By electrolysis, a protective oxide layer is created on the aluminum sheet's surface. Anodized aluminum sheets provide excellent resistance to corrosion, increased durability, and can be colored or dyed for aesthetic enhancement. 2. Powder Coating: Dry powder is applied to the aluminum sheet and then cured through heat, resulting in a tough and durable coating. Powder-coated aluminum sheets offer exceptional resistance to corrosion, abrasion, and fading, and come in a wide range of colors. 3. Polishing: Imperfections on the aluminum sheet's surface are removed through polishing, resulting in a smooth and shiny finish. This treatment is commonly used for decorative purposes to enhance the visual appeal of marine-grade aluminum sheets. 4. Brushing: Abrasive pads or brushes are used to create a textured surface on the aluminum sheet. Brushing is often employed to conceal scratches or imperfections and can provide a unique aesthetic appearance. 5. Chemical Conversion Coating: A chemical solution is applied to the aluminum sheet, reacting with the surface to form a protective coating. Chemical conversion coatings enhance the aluminum's corrosion resistance and can also serve as a base for further surface treatments, such as painting. 6. Clear Coating: A transparent protective layer is applied to the aluminum sheet. Clear coating helps prevent corrosion and oxidation while maintaining the natural appearance of the aluminum surface. When selecting a surface treatment, it is crucial to consider the specific requirements and intended use of the marine-grade aluminum sheets. Each treatment offers different characteristics in terms of corrosion resistance, durability, aesthetics, and cost, allowing for customization based on the application's specific needs.

- Q:What are the standard sizes of aluminum sheets?

- The standard sizes of aluminum sheets can vary depending on the manufacturer and specific requirements. However, some commonly available standard sizes for aluminum sheets include 4 feet by 8 feet (1.2 meters by 2.4 meters), 4 feet by 10 feet (1.2 meters by 3 meters), and 5 feet by 10 feet (1.5 meters by 3 meters). These sizes are widely used in various industries and are readily available in the market. Additionally, custom sizes can also be obtained through specialized aluminum sheet suppliers to meet specific project needs.

- Q:What are the cost considerations when purchasing aluminum sheets?

- There are various factors to keep in mind when buying aluminum sheets that affect their cost. Firstly, the price of aluminum sheets is determined by the current market conditions. Factors such as supply and demand, global economic conditions, and geopolitical events influence the price. Therefore, it is important to stay updated on market trends and fluctuations to ensure an informed purchasing decision. Another consideration is the quantity of aluminum sheets needed. Buying in bulk or larger quantities often results in lower costs per unit. However, it is crucial to accurately assess the required quantity to avoid excess inventory and unnecessary expenses. Additionally, the grade and quality of aluminum sheets can impact their price. Aluminum sheets come in various grades, each with specific properties and performance characteristics. Higher-grade aluminum sheets, which have superior strength or corrosion resistance, tend to be more expensive. It is important to evaluate the project's specific requirements to determine the appropriate grade of aluminum sheets needed. Transportation costs should also be taken into account. Depending on the supplier's location and the quantity ordered, shipping expenses can vary significantly. Exploring different shipping options and negotiating favorable terms can help minimize transportation costs. Lastly, additional costs such as processing, finishing, and customization should be considered. Some projects may require services like cutting, bending, or coating the aluminum sheets, which can add to the overall cost. However, these services may be necessary to meet specific project requirements. In conclusion, it is crucial to consider the current market price, required quantity, grade and quality, transportation costs, and any additional processing or customization needs when purchasing aluminum sheets. By carefully evaluating these factors, one can make an informed decision and ensure the best value for their investment.

- Q:Aluminum standard 30*25*2500 to 1000 1 how to calculate the number of materials needed?. 2 how to calculate the cutting loss?

- The aluminum density of the alloy is about the same as this one, which can be roughly estimated.

- Q:My frame snapped and I want to fix it by welding it back together. In order to do that, I need to know what all is in the aluminum.

- You can NOT weld back an aluminum frame unless you have the facilities to anneal and heat treat the frame again. Rewelding without the post treatments will result in a very soft area around the new weld causing sudden catastrophic failure... this means if you are riding it could fail at any time causing injury or death. EDIT: Wait just a durn minute. The 2100 and 2300 had carbon fiber tubes bonded to aluminum lugs and stays. If your bike failed then you ABSOLUTELY should not try to weld it. The heat from welding (even if you had post treatment facilities) would destroy the bond between the CF and aluminum. Fair warning- cut the frame apart and throw it away.

- Q:How do aluminum sheets perform in terms of thermal insulation?

- When it comes to thermal insulation, aluminum sheets are not efficient. Their high thermal conductivity allows heat to easily pass through them, making them ineffective in blocking or resisting heat transfer. As a result, their thermal insulation properties are poor. If your main concern is thermal insulation, it would be more appropriate to consider other materials like fiberglass, foam, or mineral wool as they would be better suited for the task.

- Q:Are aluminum sheets suitable for heat exchangers?

- Yes, aluminum sheets are suitable for heat exchangers. Aluminum is a highly conductive metal, which allows for efficient heat transfer. Its lightweight nature makes it easy to handle and install in heat exchanger systems. Additionally, aluminum is highly resistant to corrosion, ensuring the longevity and durability of the heat exchanger. Furthermore, aluminum sheets can be easily formed into different shapes and sizes, making them customizable for various heat exchanger designs. Overall, aluminum sheets offer excellent thermal conductivity, corrosion resistance, and versatility, making them a suitable choice for heat exchanger applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mill Finish Five Bar Aluminium Treadplates 5052 HO for Boat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords