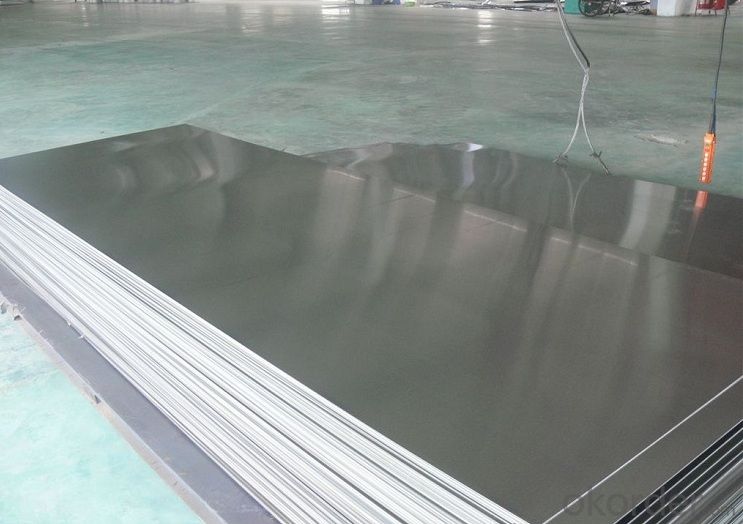

Mill Finish Aluminium Sheet for Shipbuilding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Mill Finish Aluminium Sheet for Shipbuilding

l Other Product Description

1. | Item | Aluminum plate/ Aluminum sheet, aluminium plate price, aluminium chequer plate, aluminium sheet, aluminium sheet price | |

2. | Standard | ATSTM,AISI,JIS,EN,GB | |

3. | Material | 1060, 1200, 1100, A1100P, 3003, 3004, 5052, 5652, 5154, 5254, 5454, 5083, 5086, 5056, 5456, 2A21, 2024, 2014, 6061, 6063, 7072, 7075,etc. | |

4. | Specifications | Thickness | 0.5mm~200mm |

Width | 100mm~2200mm | ||

Length | 2m, 3m, 5.8m, 6m or as required | ||

6. | Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. | |

7. | Price Term | FOB, CIF , CFR, etc. | |

8. | Payment Term | T/T, L/C, Western Union, etc. | |

9. | Delivery Time | According to order’s quantity. | |

11. | Package | Export standard package: bundled wooden box, suit for all kinds of transport, or be required. | |

12. | Application | 1) Kitchenware, food and chemical products processing and storage devices; 2) Aircraft fuel tanks, oil pipe, rivets, wire; 3) Cans cover, car body panels, steering plates, stiffeners, brackets and other components; 4) Manufacturing trucks, tower building, ship, train, furniture, machinery parts, precision machining with the tubes, rods, shaped, sheet metal. | |

l Packaging & Delivery

Packaging detail: Export standard package: bundled wooden box, suit for all kinds of transport, or be required.

Delivery detail: about 25 days from received original L/C or advance payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q:Are aluminum sheets suitable for marine vessel construction?

- Yes, aluminum sheets are suitable for marine vessel construction. Aluminum is a lightweight yet strong material that offers excellent corrosion resistance in marine environments. It is commonly used in the construction of various marine vessels, including boats, ships, and yachts. One of the main advantages of using aluminum sheets in marine vessel construction is their high strength-to-weight ratio. This allows for the construction of lighter vessels, which can result in improved fuel efficiency, increased speed, and better handling. Additionally, the lightweight nature of aluminum makes it easier to transport and maneuver during the construction process. Another key benefit of aluminum sheets for marine vessel construction is their exceptional resistance to corrosion. Aluminum naturally forms a protective oxide layer on its surface, which prevents further oxidation and corrosion. This makes aluminum an ideal choice for marine environments, where vessels are constantly exposed to saltwater, humidity, and other corrosive elements. Furthermore, aluminum sheets can be easily fabricated and welded, providing flexibility in the design and construction of marine vessels. They can be shaped into various forms, allowing for the creation of complex hull structures and interior components. Aluminum also offers good thermal conductivity, which can help regulate temperature in the interior spaces of marine vessels. While aluminum sheets have many advantages for marine vessel construction, it is important to consider certain factors. Aluminum is susceptible to galvanic corrosion when it comes into contact with certain metals, such as steel or bronze. Therefore, proper insulation and anti-corrosion measures should be taken to prevent galvanic corrosion in aluminum-based vessels. In conclusion, aluminum sheets are highly suitable for marine vessel construction. Their lightweight, high strength-to-weight ratio, corrosion resistance, and ease of fabrication make them an ideal choice for building durable and efficient marine vessels. However, proper precautions should be taken to prevent galvanic corrosion when aluminum is used alongside other metals.

- Q:Can aluminum sheets be recycled?

- Yes, aluminum sheets can be recycled. Aluminum is a highly recyclable material, and recycling aluminum sheets helps in conserving natural resources and reducing energy consumption compared to producing new sheets from raw materials.

- Q:Can aluminum sheets be used for decorative wall panels?

- Aluminum sheets are indeed suitable for decorative wall panels. As a versatile material, aluminum offers a wide array of design options for wall panels. It is lightweight, durable, and resistant to corrosion, making it perfect for both indoor and outdoor applications. Aluminum sheets can be easily cut, formed, and fabricated into various shapes, patterns, and finishes, allowing for limitless design possibilities. Moreover, aluminum can be enhanced in appearance and provided with extra protection against wear and tear through powder-coating or anodizing. Whether it's for residential or commercial spaces, aluminum sheets can impart a modern and stylish touch to any wall, rendering them a highly sought-after choice for decorative wall panels.

- Q:How thick are aluminum sheets commonly available?

- Aluminum sheets commonly come in various thicknesses, depending on the intended use and application. The most commonly available aluminum sheet thicknesses range from 0.025 inches (0.63 mm) to 0.125 inches (3.18 mm). However, thinner and thicker aluminum sheets are also available, with some going as thin as 0.016 inches (0.4 mm) and others as thick as 0.25 inches (6.35 mm) or more. The specific thickness required will depend on the specific project or industry application.

- Q:Can the aluminum sheets be used for manufacturing solar panel frames?

- Yes, aluminum sheets can be used for manufacturing solar panel frames. Aluminum is a commonly used material in the solar industry due to its lightweight, durability, and corrosion resistance. It is an ideal choice for solar panel frames as it provides structural support while being able to withstand various weather conditions. Additionally, aluminum is easily recyclable, making it an environmentally friendly option for solar panel manufacturers. Overall, aluminum sheets are a suitable material for manufacturing solar panel frames.

- Q:Bauxite ore contains aluminum oxide, which is decomposed using electricity to produce aluminum metal and oxygen. What mass of aluminum metal can be produced from 125 g of aluminum oxide?I'm really confused and I need help. Thanks.

- That's a good question, I was wondering the same thing myself

- Q:How to press multilayer aluminum sheets (aluminum sheet's thickness: 0.2mm) together and keep them inseperate after pressing?

- resistance welding is a welding method that pressing the materials to be welded in an area between two poles and switching on current. the current will go through the contact surface and agjacent area, producing resistance heat effect which will heatthe materials into melting or plastic state and make the materials be welded together.

- Q:Are aluminum sheets suitable for food processing equipment?

- Yes, aluminum sheets are suitable for food processing equipment. They are widely used in the food industry due to their excellent heat conductivity, corrosion resistance, and easy maintenance. Additionally, aluminum is non-toxic and does not react with food, making it a safe and hygienic choice for food processing equipment.

- Q:how to produce aluminium sheet circle?

- As for the process, you can use punch.. as for professional machines, for example, stationary press in open type, mechanical press/ single-point press. The material you say is neither big nor small, blanking…(cutting them into sheet circle you want) you can add an uncoiling if it’s coil stock: open-type inclinable press, four-point press,ect. It’s not certainly accurate) punch, oil press, double , four-column hydraulic (oil) press,etc. it needs about 315T,(estimated value, closed type single, blank material cutting (cutting into square ) 2, it contains sheet metal forming technology, crank press: 1: straight side two : 1, but the components you said is simple, only two steps.

- Q:I may use the copper or brass for an inlay on a decorative piece of aluminum I'm working on.....

- This Site Might Help You. RE: which has the lower melting temperature....aluminum, copper, or brass...can you list all 3? I may use the copper or brass for an inlay on a decorative piece of aluminum I'm working on.....

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mill Finish Aluminium Sheet for Shipbuilding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords