Manual Edge Banding Machine For Wood Working

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pcs pc

- Supply Capability:

- 10000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Manual Edge Banding Machine for wood working

This Kind of Manual Edge Banding Machine is our main product of Edge Banding Machine Series. With comprehensive range ,it includes automatic edge banding machine, semi-auto edge banding machine ,automatic shaped edge banding machine and so on .As an important process in panel furniture and cabinet making process ,edge banding takes a great role in determining the quality ,price and level of furniture. Edge banding process will embellish the profile of furniture, protect the corner from wearing out, avoid the veneer lifting, while transferring and using. Besides, edge banding is also a way to proof water and harmful air, which may destroy our health .VE series edge banding machine is able to process chipboard, MDF board, and other manmade board with with PVC, melamine and veneer .We produce kinds of edge banding machines to meet different needs of our consumers .

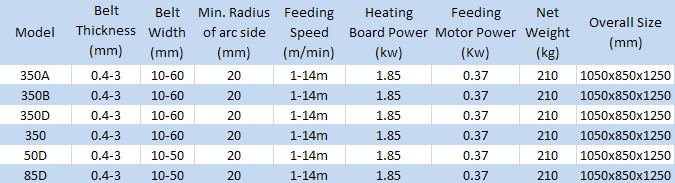

Specifications of Manual Edge Banding Machine for wood working

Advantages of Manual Edge Banding Machine for wood working

1. Easy operation.It can band the straight edge

2. Feedstock use the frequency transformer to adjust the speed

3. Having the auxiliary heating to ensure the glue flows smoothly

4. Woodworking Edge binding Machine with special design for glue systems, structural stability, long service life, coating uniformity and it will not leak glue

5. Multi-functional, can adapt to a variety of materials and sizes to provide a straight edge inside the arc, outside the arc, with curves and with circle

6. Automatically controls heat to reach set temperatures.Speed control can adjust banding speed to work at your pace

Package of Manual Edge Banding Machine for wood working

- Q:9 eco plates can edge it?

- Yes, it is a kind of material used to protect, decorate and beautify the furniture, plates and sections. It can make the furniture appear clear and colorful. If the process is good, the problem is not large. But the edge of various plates is different (due to the different thickness of the plate). Where to buy plate, who will be the edge banding?. Remember! Good steel used in the blade, to superior material, buy Decorative Building Materials website, choose some good material, use also save worry and effort.

- Q:Line edge to use what glue

- White latex or foam gum can be used.1, this depends on what the edge material is used, the general edge of the material does not need glue, directly with foam glue on the line, such as non solid wood edge material, foam adhesive can be good.2, if you want a better effect, you can use white latex, and some solid wood edge material, with white latex treatment more fine, longer service life.3, of course, buy edge banding material is optional adhesive.

- Q:Is it easy to use an edge seal? Which one is better than a nail free glue?

- Edge sealing spirit is an aquatic product. The initial adhesive force and weather resistance are different from those of nail free gum.

- Q:Whether or not the upper and lower frames of the solid wood composite door bear edges?

- General composite doors are done edge, except paint......

- Q:Method for using small-sized edge banding machine

- What type of edge banding machine?

- Q:What kind of beam is an edge banding beam?

- Usually LL or L beams... The atlas is subordinate to the secondary girder category...Play a decorative role..

- Q:I sell cabinets, and now the price of pressure is very serious, I would like to do their own cabinets, I would like to ask banding machine what kind of cheap and convenient?

- Well, the cabinet cabinet is mainly edge banding machine, or better point

- Q:Melamine laminate veneer how edge?

- PVC edge banding can be used, edge banding, automatic edge banding machine is more simple.

- Q:Is there an environmentally friendly adhesive tape?

- Good water sealing rubber Kang is beautiful this year's first environmentally friendly products and culture. Beauty Jia Kang edge glue non-toxic, tasteless, pure green products.

- Q:I am a furniture factory, need a lot, it is best to paint to dry is the best, the ash inside the shop, if the dry time is too slow for local repair will be dust, it will look at the dust, affect the quality of the product.

- Or engage in equipment, see what reason end edge after the show mainly has several aspects, one is only one side of the saw, if it is open at the end, you saw the small saw blade is too high, it low, or with a pre wash milling is good, if the two sides open at the end, it is too big to glue look, what reason, if it is winter, due to low environmental temperature, glue just painted on the solidification, the pressure is not real, for glue, stick firmly, installing plate preheating device can solve the problem, the problem is not winter, edge glue painted edgeband sub pressure wheel pressure is not enough no, pressure, or your gum is not good quality, short solidification time, low temperature may also glue you to adjust, will cause this situation. If your edgeband side open at the end, it is your problem finishing knife adjustment, adjustment is too large, it is good to adjust

1. Manufacturer Overview |

|

|---|---|

| Location | Guangzhou, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 2 Million |

| Main Markets | Southeast Asia |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shunde; Guangzhou |

| Export Percentage | 5% - 10% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | Chinese |

| b)Factory Information | |

| Factory Size: | Above 4,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Manual Edge Banding Machine For Wood Working

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pcs pc

- Supply Capability:

- 10000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords