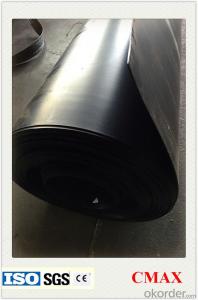

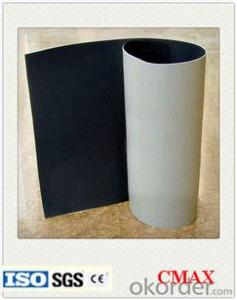

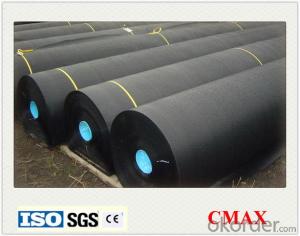

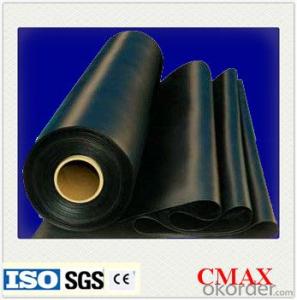

LDPE/HDPE/LLDPE Geomembrane with Thickness 0.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

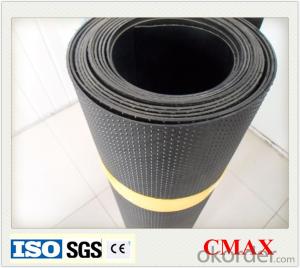

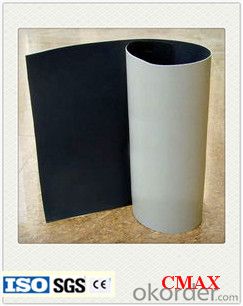

LDPE/HDPE/LLDPE Geomembrane 100% Virgin Material

Description

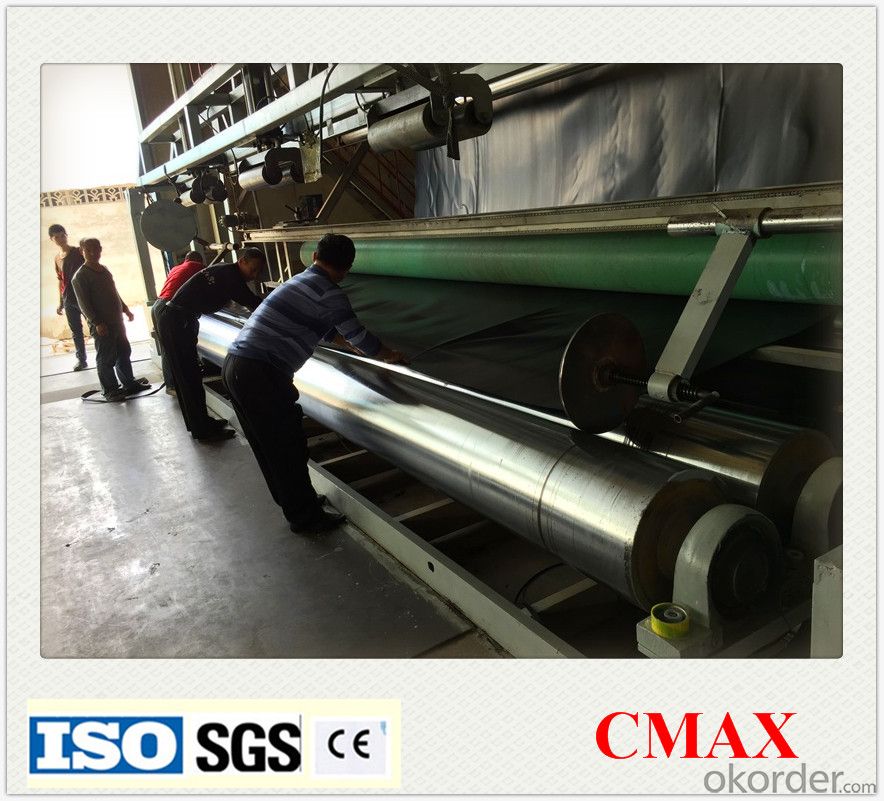

Geomembrane is made from LDPE, LLDPE, HDPE, EVA resin and additives such as antioxidant, carbon black, master batch etc with the method of 1 layer extrusion and 3 layers co-extrusion in high temperature.

Specification

1. Thickness: 0.1mm-3.0mm

2. 4m-9m in roll width, the length as clients' request.

Property:

Excellent waterproof, heat preservation, easy for welding, chemical and UV resistance.

Application:

1.landfill,sewage or control the waste residue seashores seepage.

2.Lake dam,tailings dams,sewage dam and reservoir,channel,storage of liquid pools(pit,ore)

3.The subway ,tunnel,anti-seepage lining of basement and tunnel.

4.To control the roadbed and other foundation saline seepage.

5.Dike,the front of the sam foundation seepage prevention bedding,level of vertical impervious layer , construction cofferdam,waste field.

6.Seawater,freshwater fish farms.

7.Highway,the foundations of the highway and railway;the expansive soil and collapsible loess of the waterproof layer.

8.Anti-seepage of roofing

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 sqm.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q:What are the features of film mulching door sheet?

- 1. Eco-friendly, non-toxic and non polluting raw materials do no harm to the environment and users because the harmful matter has been removed through special refining. Heavy metals (such as lead) are not suitable for the stabilizer. 2. The color is natural and realistic, and the dye is stable without difference, the color of moulded cabinet panel is bright, the pattern is natural and realistic, and the film color of each batch is consistent. 3. Stain-resistant and easy- to-clean film surface will not generate static?electricity to absorb dust and the oil stain or stains on the surface canbe removes with ordinary cleanser within 12 hours, leaving no trace. 4. scratch, wear, moisture and temperature resistant. If you scratch the surface with fingernails, no traces will leave. If you wash the cabinet, the surface color will not change or fade. If you use it in humid environment within 85°, it will not degum. 5. anti-light, non-discolouring, fastness. Shaped panel color will not change when it is used indoors and the white panel will not turn yellow. 6. Although the color of filmed board is not as various as mirror board, the fashionable designs?and?colours can meet the individual needs.

- Q:Are geomembranes resistant to abrasion?

- Yes, geomembranes are generally resistant to abrasion due to their high tensile strength and durability. They are designed to withstand wear and tear caused by friction, making them suitable for various applications such as lining ponds, landfills, and mining sites.

- Q:How are geomembranes used in construction projects?

- Geomembranes are used in construction projects as a barrier or liner to prevent the leakage or seepage of fluids, such as water or chemicals, in various applications such as landfills, reservoirs, and containment ponds. They provide a reliable and cost-effective solution to control and manage the flow of fluids, protecting the environment and ensuring the integrity of the construction project.

- Q:what is the film-drawing ceiling

- film-drawing ceiling introduction the film-drawing ceiling is introduced by foreign, which has ten performance and one hundred kinds of colors and fabrics with alternative, it is novel and beautiful, safe, durable, modelling diversity and quick installation, and suitable for any occasion. Scope of application: Home, apartment, office, workshop, conference room, computer room, hospital, school, cinema, hotel room, club, swimming pool, bathroom, Cara OK room, commercial premises, exhibition hall layout, etc.. Type 1, optical mask: It has strong light sensation, and can produce reflective effect similar to a mirror, it is mostly used for entertainment venues! 2, transparent film: It is milky white and translucent, the light transmission rate is 75%, and it can produce perfect and unique lighting decorative effect the lights, and it can be exclusively used in T4, T5 modulator tube and LED lamp. 3, Satin light film: It has fine stripes, the light perception ranks only second to optical mask, the overall effect is pure and elegant. 4, whale leather: The surface was villous, the overall effect is high-end, gorgeous, excellent sound absorption performance, which can create a warm interior effect. 5, metal surface: It has a strong metal texture, and can produce light metal, and has very strong ornamental effect. 6, pore membrane: The surface can be made of various specifications of small holes, light can play a variety of light through the hole! 7, mirror mask: There are white and yellow two colors and strong light sensation, which like a mirror. 8, painted film: There are marble, water and other kinds of patterns, it is translucent, and it will produce a good effect with light!

- Q:How is the oil film on the fish tank produced?

- The environment of fish tank is the same with the sea. When it is contaminated or the self-renewal ability reduces (for example when the water is seldom changed), water will be eutrophication. Besides, sunshine is plenty and green algae overgrowths, which will consume a large amount of dissolved oxygen in water. This is the principle of green tide.

- Q:What's the repair method of membrane keyboard?

- Membrane repair is a little difficult. First you need to find out where goes wrong. Cut off part of the thin iron wire which is a little longer than that of the damaged circuit, cut off a section of scotch tape, put the iron wire clipped with tweezers on the scotch tape, align the tweezers with the circuit, adhere the circuit to the tape and press, and the problem is solved.

- Q:Is it useful to stick film for iPhone?

- Yes, it is. 1. The gardness of iPhone glass is larger than fingernails and metals like keys, so these things scratch it. 2. Many components in dust and sand wind, such as quartz, is harder than the glass. For example, if some grains of sand containing quartz in your hand, they will cause permanent scratches to the iPhone glass. 3. In terms of the service time, the mobile phone is a durable product, but after 2 or 3 years, you will buy a new one. 4. Therefore, if you use it carefully and do not mind scratches, you need not to stick film, otherwise you had better stick film.

- Q:How do geomembranes help with water storage and containment?

- Geomembranes help with water storage and containment by creating a reliable barrier between the water and the surrounding environment. They are impermeable liners made of synthetic materials that prevent water from seeping into the ground or escaping into nearby areas. This allows for efficient storage and containment of water, reducing the risk of water loss, contamination, and damage to the surrounding ecosystem.

- Q:How to install soft membrane ceiling in conference room?

- Step 1 of soft membrane ceiling installation in conference room: 1. In accordance with the requirements of design drawings, fix a circle of supporting keel (batten or steel pipe) around the place to install soft membrane ceiling. (See construction design drawing).Note: in some large places, you need to install by block to achieve good results. In this case, you need to add batten in between. This depends on actual situation. 2. When all required battens are fixed, install and fix aluminium?alloykeel of soft membrane ceiling in the bottom of supporting keel. (See construction design drawing) Step two: 1. When all installation of aluminum keels of soft membrane ceiling are fixed, install soft membrane. First open soft membrane and heat sufficiently and evenly with dedicated heater, then insert the soft membrane into aluminium alloy keel with dedicated slotting tool, and finally cut the surrounding spare soft membrane. (See detailed construction design) 2. After installation, use a clean towel to clean soft film smallpox.

- Q:Can geomembranes be used in stormwater retention ponds?

- Yes, geomembranes can be used in stormwater retention ponds. They are often installed as liners to prevent seepage and leakage of stormwater into the ground, ensuring the pond functions effectively in retaining and managing stormwater.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

LDPE/HDPE/LLDPE Geomembrane with Thickness 0.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords