LDPE Geomembrane Black Plastic Sheeting

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Type: | Geomembranes | Place of Origin: | Shandong, China (Mainland) | Brand Name: | CMAX |

Model Number: | 0.1mm-4.0mm | Material: | EVA, HDPE, LDPE, LLDPE, PVC, HDPE | Thickness: | 0.1mm - 4.0mm |

Color: | white, black, red ect. | Roll width: | 1m-8m | Roll length: | 50-100m |

MOQ: | 100 m2 | Certification: | CE/ISO9001/ ISO14001 | Sample: | available for free |

Package: | by PP woven bag | Payment: | by T/T |

Packaging & Delivery

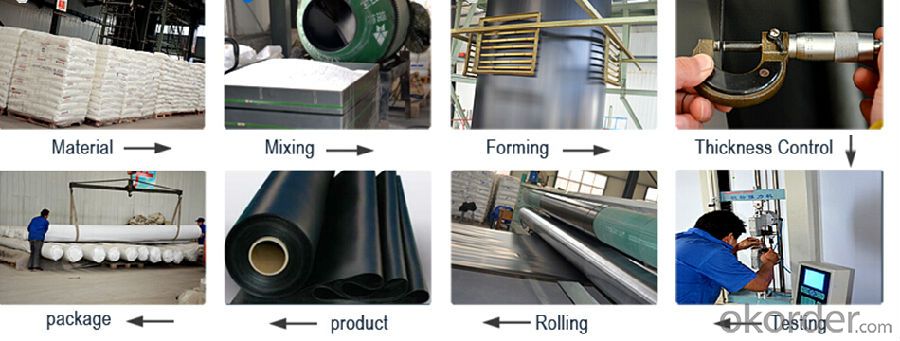

Packaging Details: | HDPE geomembrane are packed into roll in PP woven geotextile or as client' s request |

Delivery Detail: | in 10 days after receive advance payment |

HDPE geomembrane

HDPE geomembrane specifications

1) thickness : 0.1mm - 4.0mm.

2) width : Within 8 m (1m-8m).

3) length : 50-100m/roll (as request).

4) Material : HDPE,( LDPE, LLDPE, PVC, EVA ,CPE).

5) Color : Black , white , red , blue , or as required.

6) Products supervised by Mr. Wang -- international geosynthetics expert.

7) Anti - UV / Anti - Aging / High Strength / anti-corrosion / high temperature-resistant / non-toxic.

8) Charge to provide the construction ( customer pay the wages of workmen) , Free to provide professional solutions.

9) Products supervised by international geosynthetics expert Mr.Wang , we also have professional engineers team provide the most professional solution for you.

HDPE geomembrane Feature

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance,

anti-aging, anti-ultraviolet-resistant,

Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water,

drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications

and low cost, simple construction.

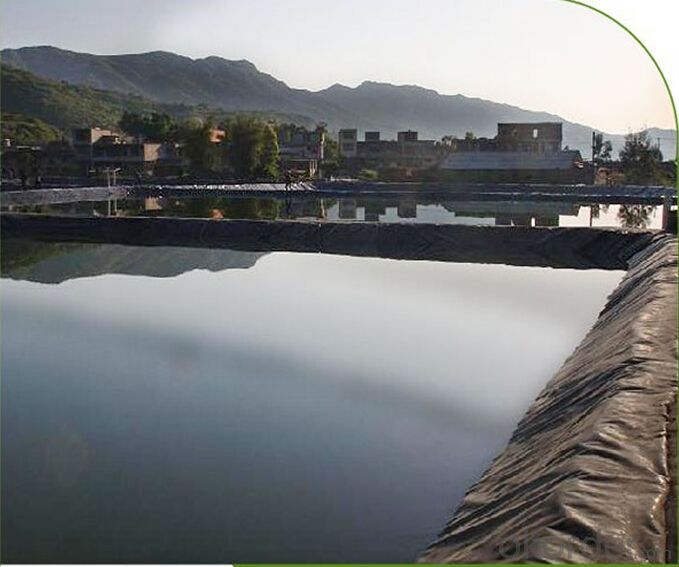

HDPE geomembrane Product Application

1) Environmental protection sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

HDPE geomembrane technical index of ASTM test GM 13 standard

No. | Item | Test Value | ||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 2.0 mm | 2.5 mm | 3.0mm | ||

1 | Minimum Density(g/cm³) | 0.939 | ||||||

2

| Tensile Property | |||||||

Strength at yield,N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | |

Strength at break ,N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | |

Elongation at yield,% | 12 | |||||||

Elongation at break,% | 700 | |||||||

3 | Tear Resistance N | 93 | 125 | 156 | 187 | 249 | 311 | 374 |

4 | Puncture Resistance N | 240 | 320 | 400 | 480 | 640 | 800 | 960 |

5 | Stress Crack Resistance, hrs | 300 | ||||||

6 | Carbon Black Content, % | 2.0-3.0 | ||||||

Carbon Black Dispersion | 1 or 2 | |||||||

7 | Standard OTI Min | 100 | ||||||

High Pressure OTI Min | 400 | |||||||

8 | Impact Cold Crack at -70°C | Pass | ||||||

9 | Water vapor permeability (gNaN/cm2 .s.Pa) | ≤1.0×10-13 | ||||||

10 | Dimensional Stability (%) | ±2 | ||||||

- Q:Water is the water base wallpaper wallpaper glue?

- The wallpaper film is a kind of surface treatment liquid befored the wallpaper is pasted. If the wall has brushed varnish, wallpaper primer can not used, but wallpaper primer is more environmentally friendly, dry time is faster. Ordinary wall recommend to use permeable membrane, but if it is old walls or brush metope emulsioni paint, you must first sandpaper and use the covering membrane type. " Characteristic description: Wallpaper paste on the wall, coated with a layer of wallpaper primer, it can form a compact protective layer on the wall, can effectively block water and alkaline substances on the wallpaper damage, prevent the Yellow Wallpaper, wallpaper and wall to enhance cohesion, extend the period of use of wallpaper. The function of the basement membrane is curing and protection putty surface, it also can strengthen the function of alkali resistant wallpaper. In the basement membrane of the putty is completely dry after. And as for wallpaper glue, the focus falls on the glue, is used to stick wallpaper, stick wallpaper, ensuring wallpaper's life is the most basic function

- Q:How to choose glossy and matte geomembrane used in refuse landfill ?

- Hope it is easy to understand because it is not complicated at all. Actually, the dfference between matte and glossy membrane is the coarse surface, which is to increase friction. I f it is for refuse landfill, there are mainly three parts needed geomembrane for seepage-proof. reservoir bottom, side slope and cover (or closure). For "reservior bottom" , pave a layer of imported glossy geomembrane at the bottom of the landfill for horizontal seepage prevention. For side slope, use matte geomembrane around the landfill to increase friction because the side slope has vertical angle, that is, to make the geomembrane hung on the side slope. For cover or enclosure, use glossy membrane for horizontal seepage prevention to prevent rain pouring into the reservior and percolate increasing and isolate the garbage in landfill from the outside. It may not be comprehensive, but from practical experience coorperated with Canada Solmax Inc. Hope it's helpful.

- Q:What are the common sizes available for geomembranes?

- The common sizes available for geomembranes vary depending on the specific project requirements, but they typically range from 20 to 100 feet in width and can be manufactured in lengths up to several hundred feet.

- Q:What is geosynthetics reinforced base?

- When bases of buildings are constructed with soil (sandy material) and geosynthetics beneath the soil, the geosynthetics can be monolayer or multilayer with superficial layer foundation. As civil engineering material, geosynthetics are made from synthetic polymer (such as plastic, chemical fiber, synthetic rubber). It can be embedded into soil mass or on the surface of soil to reinforce or protect the soil. "Technical code for application of geosynthetics" divides the geosynthetics into four categories, namely the geotextile, geomembrane, geocomposite, and special materials.

- Q:what's the pneumatic membrane valve mechanism?

- the pneumatic membrane valve mechanism are as follow: Pneumatic diaphragm control valve by the pneumatic membrane actuator mechanism and a valve body is composed of two parts, body structure is generally straight stroke type, the common part are single seater, two seater, sleeve, angle, three links, skateboarding, diaphragm structure. it is mainly by the valve cover, valve core, valve seat, valve stem, stuffing box, etc.. Upper end of the valve rod and thin film institutions push rod connected to the lower end, putting drives the valve rod to move, so that spool movement, changing the flow of fluid between the spool and the valve seat area, thus changing the flow of the fluid, to achieve the purpose of regulating.

- Q:What are the advantages of using geomembranes in industrial wastewater treatment?

- There are several advantages of using geomembranes in industrial wastewater treatment. Firstly, geomembranes act as a barrier, preventing the contamination of soil and groundwater by containing the wastewater. This helps to protect the environment and ensure compliance with regulations. Secondly, geomembranes are highly resistant to chemical degradation, making them ideal for handling and treating industrial wastewater that may contain hazardous substances. They provide a reliable and durable solution for containing and treating wastewater in harsh industrial environments. Furthermore, geomembranes offer flexibility in design and installation, allowing for customization to fit specific site requirements. They can be easily fabricated into different shapes and sizes, ensuring an efficient and effective wastewater treatment system. Additionally, geomembranes have low maintenance requirements and a long lifespan, reducing operational costs over time. They are also relatively easy to install and repair, minimizing downtime and ensuring continuous wastewater treatment operations. Lastly, the use of geomembranes in industrial wastewater treatment helps to improve overall efficiency by facilitating the separation of contaminants from water. This leads to cleaner water for reuse or discharge, contributing to water conservation and sustainable practices. In summary, the advantages of using geomembranes in industrial wastewater treatment include environmental protection, chemical resistance, flexibility, low maintenance, and improved efficiency.

- Q:How do geomembranes help in preventing soil compaction?

- Geomembranes act as a barrier between the soil and external forces, such as heavy machinery or vehicles, which helps in preventing soil compaction. By distributing the weight over a larger area, geomembranes reduce the pressure applied directly on the soil, minimizing the chances of compaction.

- Q:How do geomembranes help with pond lining?

- Geomembranes help with pond lining by providing a durable and impermeable barrier that prevents water seepage and leakage. They act as a protective layer, ensuring that the pond remains watertight and retains its intended water level. Additionally, geomembranes can also prevent the infiltration of contaminants from the surrounding soil, enhancing the water quality and promoting a healthier pond ecosystem.

- Q:in what areas does geomembrane usually apply? Please recommend cost-effective geomembrane.

- Clean water such as reservoir, and the pool also uses flexible impermeable geomembrane which is a typical representative of the flexible seepage proof material. seepage-proof geomembrane is preferable to a large area needs leakage pollution prevention like residue field. Cost-effective. The advantage is to prevent liquid leakage, mining waste water, sewage, petrochemical wastewater.

- Q:Is electrothermal?film heater good?

- Electrothermal film heater is not very ideal, because ports must be left for each films, and it must be done on site, if workers are not professional enough, there will be many problems, the most troublesome is that the floor has to be prized up.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

LDPE Geomembrane Black Plastic Sheeting

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords