Hydraulic Crawler Excavators (SC270LC. 8)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

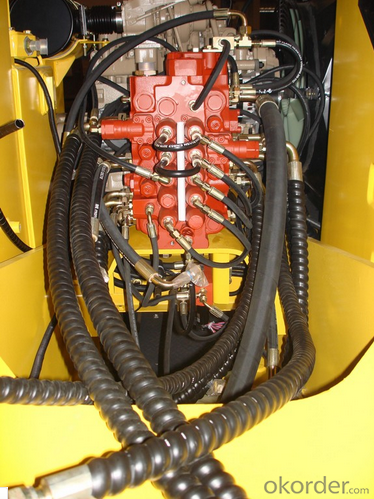

SC270LC. 8 crawler excavators Hydraulic Crawler Excavators (SC270LC. 8)

1) U. S. A imported geniune Cummins engine

2) Japanese Kawasaki geniune hydraulic pump, valve and swing motor.

3) Japanese Kayaba geniune travel motor.

4) Shantui industrial park made crawler and rollers

5) World famous electric parts

6) Komatsu KES standard production.

7) Auxilary cabin with A/C and pilot control

Specification Hydraulic Crawler Excavators (SC270LC. 8)

Model NO.:SC270LC. 8

Drive Type:Hydraulic Drive

Bucket Capacity:1.0~1.5m³

Transmission:Hydraulic Transmission

Type:Crawler Excavator

Size:Large-Scale

Condition:New

Certification:ISO9001: 2000

Bucket:Grab Shovel

Operating Weight:27.5 T

Export Markets:Global

FAQ Hydraulic Crawler Excavators (SC270LC. 8):

1.How about the shipment?

1. The loader machine load one 40HQ container.

2. The loader disassemble into 3 parts, major machine, bucket and cabin.

3. Before shipment, we have done the rust-proof and antiseptic treatment.

2. What about your service?

We have our factory, we can meet customers needs as soon as possible.

We have first rate professional technology and provide good after-sales service.

3. What Can we Do For You?

1. During the period of 12 months or 2000 working hours warranty, Chaogong factory are responsible for maintenance and replacement of spare parts.

2. We attend the machinery exhibition in your country and please contact us when we are with you at that time and solve the problem you have.

3. For the sole agents, we will go with senior engineer to your country and offer the technical service.

- Q:i mean young like they were 10 or 12 or 15 u know some where in there. please help1

- St. okorder

- Q:What are the salaries for 360 excavator operators in canada?

- People running diggers in Klondike goldfields make $18-25 an hour. depending on their experience.

- Q:Also, I noticed most job listings for them are temporary, how often must they relocate? Thanks

- Field techs are basic archaeological excavators. They have to have a background in archaeology (usually a field school plus a bachelors degree), and they are the ones who dig test pits for surveys, excavate sites, sift dirt to collect artifacts, map sites, and so on. Field techs do the archaeology, but they are not the one in charge of the dig. People higher up work out the funding and contracts and permits, devise the plan for how and where to dig, do the background research (though field techs are sometimes involved in that), and write the final reports. The field techs are also usually the same people who wash, label, and catalog the artifacts in the lab. Field jobs are temporary. If you work for a company that has one job after another you might have the opportunity to keep working for them on a more permanent basis, but even then there will be times when there is no work and you are laid off. Lots of companies will just hire you for a short-term job and then lay you off, so you usually need to be in contact with multiple companies if you want to stay employed. I've worked field jobs that only lasted a couple days, but I've also been a field tech at a major site where I had permanent year-round work. Field tech jobs with CRM companies on average last only a matter of weeks, or sometimes a few months. Relocating somewhere new for each project generally only works if you know the job is longer term (though you still have to relocate after 6 months or a year or two), or if you are travelling around to short term jobs that pay a per diem. For example, a company may have jobs in multiple areas-- you go to those areas for a few weeks at a time and they pay your living expenses while you are there. Lots of companies only work in a specific region, however-- if you get with them, then you'll be commuting to different sites, but can at least have a permanent residence rather than relocating.

- Q:Where should I draw the line on declaring an item a fixed asset? I have our vehicles, scissor lifts and excavators down as fixed assets, but should I also include power tools (e.g. band saws, drills, sawzalls, etc.)?As far as office equipment goes, I have declared computers, desks and filing cabinets, but what about other smaller items (e.g. desk organizers, calculators, label makers, etc.)?

- You can include all your above mentioned items, but small tools and inexpensive items may be depreciated very fast, or charged off as a daily expense when purchased. These may be listed in the case of sale of a business, but a buyer may not place much value on some. Large equipment and power tools generally have a longer life, and in some cases, such as vehicles, the IRS does not permit accelerated depreciation. Some equipment depreciation has been allowed to be accelerated in recent years but that can change periodically. New tax policies must be reviewed every year. Desk organizers and/or office supplies/stationery should not be included. These are generally considered daily expenses. Again, in a sale situation, large quantities may be considered. I'm not an accountant, but am retired after 50 years in retail. An accountant may agree or disagree with me.

- Q:Hai I am working into sales with excavator field ,i want start a small skill industrie pls guideme good bussi.

- Why okorder /

- Q:Explanation of tail slewing and tailless rotation of excavators

- The excavator can be divided into large cars, small tail car, no tail car tail car is mainly to increase body weight! The tailless rotation is that the tail of the excavator does not exceed the range of the track plate when it is rotated 360 degrees. The utility model has the advantages of flexible work, suitable for various working conditions, especially the construction of the narrow section! A tailless car is more adaptable than a tail car! The tailless vehicle is now limited to small excavators! Such as: Komatsu 55 Kobelco 55 Yanmar 55 75 Kubota 155 161

- Q:I am getting a leopard gecko and i have a 20 gallon long tank and want a safe substrate for it. I will not use sand not even calcium sand. And I don't like the way paper towel looks. Someone told me about Zoo Med Excavator Clay Burrowing Substrate. Would that be safe to use?

- I used to use Corn cob granules, which were recommended by my vet. They are safe as they prevent burns from heat mats and the gecko will not swallow them.

- Q:I have a 2004 Chevy 1500 LS extended cab z71 package with the 5.3l. This truck has the towing package such as transmission cooler factory class five hitch and 87k miles and I believe 3.73 axle ratio. I'm wondering if I can tow a 7000lb excavator plus trailer on a short trip 10-15 miles with only one somewhat major grade. I'm planning on having to take it really easy on the truck but just curious if I should forget the idea all together.

- It should be fine as long as the Silverado is equipped with the proper electric brake control and weight distribution hitch. The truck has an 8500 lb towing capacity. Bear in mind the weight of the excavator AND the trailer.

- Q:the post are very rustic almost like a tree in half do they have to have concrete around like normal fencing because the posts are morticed for the rails i have a 3 ton excavator with a small bucket any advice from an expert would be highly appreciated

- Cheap foreign labor? We never put concrete in our posts, but the ground's pretty hard here.

- Q:I was recently digging a post hole and scraped my undergound electric cable. The post hole digger damaged the insulation and scraped one of the wires. It sparked a lot then started smoking. I still had power to all parts of my house. The wire was not cut in half. Only the casing was damaged. In fear of being charged by the power company to repare the damage, I simply filled in the hole. Can anyone tell me if I can expect the exposed wire underground to give me any problems?

- The white wire is the common or neutral wire anyway and should not be carrying any voltage. Being that it is only a foot deep it was obviously added after the house was built because even direct burial U/F cable should be 2' deep per the electrical code. It possibly is an irrigation control line or landscape ltg. power line which in that case it would be low voltage. I would tape it up and forget it as well.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hydraulic Crawler Excavators (SC270LC. 8)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords