Hot DIP Galvanized Steel Coils Regular 1000mm 1250mm Z60-Z120

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

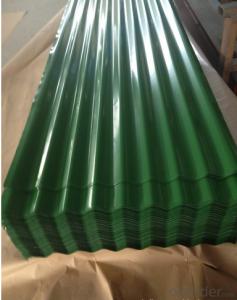

Hot DIP Galvanized Steel Coils Regular 1000mm 1250mm Z60-Z120 Dx51d+Z, DC01

Product Description

Description:

EN 10147 Structure hot dip galvanized steel coil S250GD+Z, S350GD+Z (SGC340, SS275, SS340)/Custom Deep drawing hot dip galvanized steel coil DX52D+Z, DX53D+Z, S

Galvanized steel is taken cold rolled steel as the base metal, after continuous hot dip galvanizing process, the product produced is an excellent resistance to atmospheric corrosion coating steel coil, as the steel gets coated in layers of zinc and rust won't attach this protective metal; Cold rolled plate by hot-dip galvanizing may extend the service life of 15-20 years.

For countless outdoor, marine, or industrial applications, galvanized steel is an essential fabrication component. Hot dip galvanized steel is used in applications where steel may be exposed to weather, but where stainless steel is too expensive.

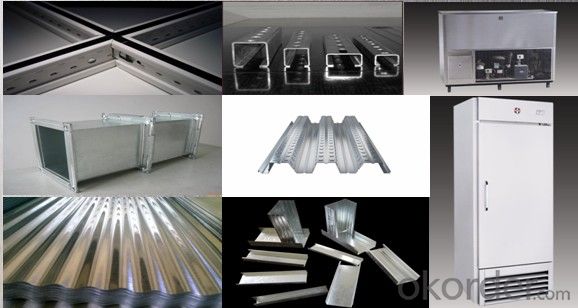

Application:

Construction

Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille

Light industries

Home appliance's case, civil chimney, kitchen utensils

Auto industry

Corrosion resistant parts of cars

Agriculture

Food storage, meat and aquatic products' freezing and processing equipment

Commerce

Equipments to store and transport materials, and packing implements

andard | EN 10142 | DX51D+Z, DX52D+Z, DX53D+Z |

JIS G3321 | SGCC, SGCD, SGCDD, SGC400 | |

ASTM A792M | CS type C, CS type B, DS, SS250 | |

Base Metal | Cold rolled steel coils SPCC, SPCD, SPCE, DC01, DC03, DC04, CS, DS, DDS, Q195, Q250, Q350 | |

Thickness | 0.14mm-3.0mm | |

Width | 600mm-1600mm | |

Coil ID | 508mm, 610mm | |

Zinc coating | 60g/m2-450g/m2 | |

Surface treating | chromium free passivation, chromium passivation, fingerprint resistant, oiled | |

Spangle types | Minimal spangle, zero spangle, regular and big spangle | |

FAQ

1.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

2. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

3.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

4. Is the sample available?

Yes, samples can be sent for test if you need.

- Q:case hardening steel is adviced or thru hardening steel is most suitable?

- I don't know your application, but here is some advice. Case hard provides a hard shell around soft steel, depending on the bake, the case is usually .002-.008 thick. (thousands of an inch) Heat treated steel or tool steel is hard all the way thru. Case hardening, provides toughness with flexibility, however, once it's compromised, the part is scrap. Hardend tool steel is extreemly hard throughout and the harder it is, the more brittle it becomes. The application of the part will help you to determine the material needed. For instance; Plastic injection molds are very hard so the hot plastic wont erode them over years of use. Punch Press dies aren't as hard but are tougher to withstand the shock. Machine bolts are case hardened so they can last, but soft enough to allow some stretching during tightening. Either way, the time in mfg will be about the same. Most tool steels today cut like cheese, but take time to be heat treated. Tool steel will cost a bit more than low carbon steel. Low carbon steel is as machinable, and cheaper, but, again, the baking period is as long or longer than tool steel. There are a lot of materials on the market today that maintain the durability of heatreated steel without having to go thru that process. 4140, ( or chrome/moly) comes to mind. There are also some 400 series stainless that work as well, and others. You need to determine strength, flexibility, ease of mfg, cost and repairability when considering which steel to use.

- Q:What are the common problems faced during steel coil production?

- Some common problems faced during steel coil production include surface defects such as scratches or dents, dimensional inconsistencies, coil breakage, edge wave formation, and coil slitting issues. Other challenges may include coil corrosion, improper coil cooling, and quality control issues.

- Q:What is the process of recycling steel coils?

- The process of recycling steel coils involves several steps. First, the steel coils are collected from various sources, such as manufacturing and construction sites. Next, the coils are transported to a recycling facility where they undergo a thorough inspection and sorting process. The coils are then cleaned to remove any contaminants or impurities. After cleaning, the steel coils are shredded into smaller pieces and melted down in a furnace. The molten steel is then molded into new coils or other steel products. Finally, the recycled steel coils are tested for quality and can be used in various industries, reducing the need for new steel production and minimizing waste.

- Q:What are the different grades of steel used in coils?

- There are several different grades of steel used in coils, including low carbon steel, high carbon steel, stainless steel, and alloy steel. Each grade has its own unique properties and is used for specific applications based on factors such as strength, durability, corrosion resistance, and formability.

- Q:What are the common international standards for steel coils?

- The common international standards for steel coils include ASTM A36/A36M, ASTM A572/A572M, ASTM A283/A283M, ASTM A516/A516M, and EN 10025-2. These standards specify the requirements for the chemical composition, mechanical properties, and dimensions of steel coils used in various industries worldwide.

- Q:What are the main factors that affect the paint adhesion on steel coils?

- The main factors that affect paint adhesion on steel coils include surface preparation, cleanliness, and the presence of contaminants such as oil, grease, or rust. Other factors include the quality of the paint itself, the application method, and the curing process. Additionally, the type of steel and its surface condition can also influence paint adhesion.

- Q:How are steel coils tested for flatness and straightness?

- Steel coils are tested for flatness and straightness using a variety of methods. One common method is to pass the coil through a series of rollers that apply pressure and measure any deviations in the surface. Another method involves using laser sensors to scan the entire coil and detect any irregularities. Additionally, visual inspections are conducted to identify any visible imperfections or distortions.

- Q:Is a steel plate the same as a steel coil?

- Generally speaking, they can be used interchangeably, and the purchase price of the plate is slightly cheaper.

- Q:What are the challenges in storing and handling steel coils?

- Storing and handling steel coils present several challenges, including their sheer weight and size, which can make transportation and storage difficult. The coils need to be stored in a way that prevents damage and deformation, as steel coils are susceptible to rust, corrosion, and scratching. Additionally, ensuring proper ventilation and moisture control is crucial to prevent the growth of mold or moisture-related damage. Safety precautions must also be taken during handling and transportation to avoid accidents or injuries.

- Q:What are the common methods of transporting steel coils?

- The common methods of transporting steel coils include flatbed trucks, rail cars, and ocean vessels.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot DIP Galvanized Steel Coils Regular 1000mm 1250mm Z60-Z120

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords