HK 2818 Drawn Cup Needle Roller Bearings HK Series High Precision

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specifications:

Specification | Model No.: HK 2818 |

Brand Name: OEM | |

Size:28*35*18mm | |

Net weight: 0.031kg | |

Material: Chrome steel | |

Cage: Brass, Steel | |

Features: | 1) Precision: P6 P5 P4 P2 |

2) Noise level: Z1, Z2, Z3, Z4 | |

3) Vibration Level: V1, V2, V3, V4 | |

4) Clearance: C2, C3, C4 | |

5) Hardness: 58-63 HRC | |

6) Greese: As your requirement, such as SRL, PS2, Alvania R12 and so on. | |

Packing | 1.Industrial packing: box |

2.Commercial packing: box then into standard carton/wooden Box | |

3.According customer's requirement | |

Payment | T/T, L/C, Western Union |

Delivery time | About 3 to 5 working days |

Services | Warrantee: 1 year |

Samples: available | |

OEM: available | |

Free technical support and after-sales service |

1.The drawn cup needle roller bearings are needle roller bearings with the deep drawn, thin-walled outer ring with either an open end or closed end.

2. The bearings are characterized by a very low sectional height and high load carrying capacity

3. The bearings are typically used in applications where the housing bore can not be used as a raceway for a needle roller and cage assembly but where a very compact and ecnomical bearing arrangement is required.

4. Typically, drawn cup needle roller bearings have a single row of rollers. However, wide sizes incorporate two needle roller and cage assemblies immediately asjacent to each other with a lubrication hole in the outer ring.

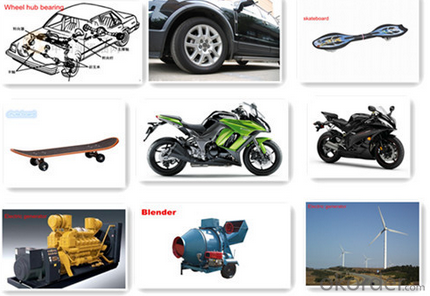

Product Applications:

Needle roller bearings are mainly used in car engines, transmissions, compressors, cranes, etc.

Our Advantages:

1. Excellent and high quality control

2. Prompt delivery

3. Competitive price

4. Small order accepted

5. Customers' drawing or samples accepted

6. OEM service

Product Advantages:

1)Bearing Manufactory ( Have our own technical department)

2)High quality products (Long Life and low noise)

3)Well-daserved Reputation (Good Stock Guarantee)

4)Professional service ( Promptly shippment)

5)OEM Service,Sample is available

FAQ:

WHY CHOOSE US ???

1.More than 28 years export experience

2.Strict quality control

3.Delivery in time

4.OEM service are available with good price

5.Low MOQ

- Q:Can anyone explain me bearings?

- Here's a video explaining bearings. Did you have a specific question regarding bearings?

- Q:Hey my friend gave me his older bearing which where speed demons and I was thinking about switching my stock 5 abec bearing which of these bearings are better for long boarding and why

- ABEC ratings are meaningless unless you are worried about small amounts of vibration over 200 mph. Really, it is a standard about vibration in high speed industrial machines. Even an ABEC 1 bearing is much better than the precision grade bearings that were used in the early skates and boards so going to ABEC was a big step up. Then the marketing people realized that they could put bigger numbers on things and the race was on. In theory, a given manufacurer puts more care into making the higher number bearings than they do the lower number bearing, but that doesn't mean that their high number bearing might not be better than a low number bearing from a better maker. In reality, the best bearing companies make non-ABEC bearings as their best ones because the smaller gaps in the high number bearings can slow you down. They put close tolerances where they need them and open up space where it can be done. They also use better grades of metal or ceramics. Within typical bearings, you will see a bigger difference due to the lubricant (and how much is used) that the bearing has in it. Oil will be faster but requires new lube more often. Grease lasts longer but is slower (especially if too much is used). Gels are in between.

- Q:what can i use 2 clean longboard/skateboard bearings besides acetone?

- Your toung.

- Q:I have recently purchased a longboard with abec 5 bearings. I have a regular board, with abec 7 bearings. I plan to use the longboard more, and i want to no if it will work to use the regular boards bearings for the longboard. Anybody know?

- regular skateboard bearings are the same as longboard bearings. i suggest getting bones reds . theyre cheap (15 bucks) and they last long. they have removable shields so theyre easy to clean. if you want a really good quality bearings, probably the bestest bearings in the world, get Swiss Ceramics. theyre expensive though (over 100 bucks) but theyre worths it.

- Q:Rods amp; bearings need to be replaced in an 98 Explorer. Need a temporary fix. Thanks.

- Hi so the idea is to make it rattle less. so a can of STP which is like treacle is added to the oil.

- Q:im sort of new and got my board at Christmas. it came as a complete board and my friends said i should get new ones but i want to clean them first to make sure i dont need new ones. and if i do what are some good brands and prices for bearings?

- Lucky bearings, black panthers, reflex or whatever just get abec 5s or abec 7s and dont pay more than $30 for them because they are all pretty much the same. and for cleaning them, just take them out of the wheel and wipe them really good with windex or whatever you have.

- Q:same with the rods? '98 eclipse with a 420a engine, manual.

- Really you need to take the head off also.It would be hard getting at the piston end bearing by just dropping the sump.

- Q:I forget hot to change the bearing s in my hockey skates, and what skates/bearings would be best for missions?

- doesnt it depend on how fast or smooth you want your wheels to turn. i believe the lower the number the better the bearing. i think my son used 2.

- Q:people always say there bearings make them go faster but i dont think this is true. in my experience its more the wheel you ride that affects speed. size hardness are both factors but bearings just dont make a significant difference. as long as they spin freely and smooth it doesnt matter whether there swiss ceramics or abec 3 because the extra friction in the threes isnt enough to slow you down. unless the threes are rusted and dont spin. is this true? would others agree? ppeople seem to think the bearings have engines or something. i just use 18 dollar redz and keep them in good shape and they work fine

- sometimes its all about the bearings if there cheap i've used speed demons witch aren't that good but i just got some element and they are why faster then the speed demons so i think it all depends on the person as they say to whom there own.

- Q:is the lucky or red bone bearings the best for making your skateboard go faster

- Reds are your best bet. Although i would recomend getting bones swiss bearing. They may be more expensive, but they are well worth it. With bones, abec doesn't matter. Abec was designed for bearings for the industrial use. Although abec 7s arw good, bones dont have abec because they dont need it. They are further designed to resist the hazards that skateboarding may have rather than most bearings.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HK 2818 Drawn Cup Needle Roller Bearings HK Series High Precision

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products