HK 1716 Drawn Cup Needle Roller Bearings HK Series High Precision

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

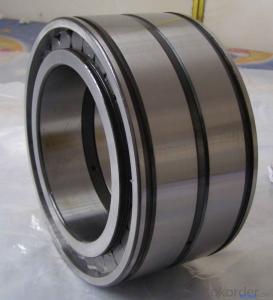

Product Specifications:

Specification | Model No.: HK 1716 |

Brand Name: OEM | |

Size:17*23*16mm | |

Net weight: 0.016kg | |

Material: Chrome steel | |

Cage: Brass, Steel | |

Features: | 1) Precision: P6 P5 P4 P2 |

2) Noise level: Z1, Z2, Z3, Z4 | |

3) Vibration Level: V1, V2, V3, V4 | |

4) Clearance: C2, C3, C4 | |

5) Hardness: 58-63 HRC | |

6) Greese: As your requirement, such as SRL, PS2, Alvania R12 and so on. | |

Packing | 1.Industrial packing: box |

2.Commercial packing: box then into standard carton/wooden Box | |

3.According customer's requirement | |

Payment | T/T, L/C, Western Union |

Delivery time | About 3 to 5 working days |

Services | Warrantee: 1 year |

Samples: available | |

OEM: available | |

Free technical support and after-sales service |

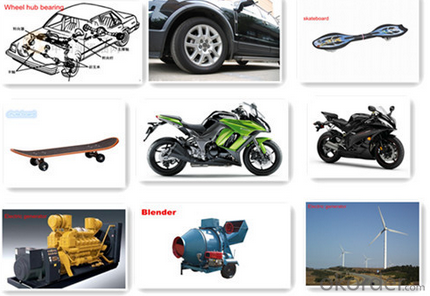

Product Applications:

Needle roller bearings are mainly used in car engines, transmissions, compressors, cranes, etc.

Our Advantages:

1. Excellent and high quality control

2. Prompt delivery

3. Competitive price

4. Small order accepted

5. Customers' drawing or samples accepted

6. OEM service

FAQ:

1.Can you make non-standard bearing?

We have great techincal team can provide

OEM service and technical support for you

2.Can you send me the free sample?

Yes.We can supply sample if have stock,we need charge freight cost or if you have courier account for freight collect .

3. How can I get more information ?

Feel free send us enquiry or call ,we do best at your service for 24 hours

- Q:i have a 20 kent bmx bike. The bearings in the frame got messed up some how and now the pedal crank moves back and forth. Can I get these the bearings or do I have to get a new frame?

- Count the number of bearings you need and take them to the local bike shop and get a whole set, don't mix the old and new ones use all new.

- Q:or the other way around?

- neither You cannot tell anything by the ABEC number. It is a spec for vibration in machinery that runs at speeds thatwouldd be over 150 mph on your board. It became popular because the precision grade bearings that used to be used are anything except precision. ABEC 1 bearings were a hugeimprovementt and the marketing people love anything they can claim higher numbers on. Inline skates and boards use the same bearings. The top makers (Zero Drag, Twin Cam, Bones) actually design their best bearings that to not meet any ABEC standard so that they can have clearances that roll better, but frequently use the number 9 (sometimes saying equivalent to ABEC) in their lit so that those who are hooked on the larger number is better BS will not avoid a numberless bearing. What is better to you? Speed? Life? Resistance to rust when you are in the rain? Know your bearing makers and what they do really well. Bones is known for rolling really well but needing more maintenance and rusting really easily. Twin cam is known for being super resistant for wet. Zero Drag is not as well known but roll very fast and are reasonably resistant to moisture.

- Q:The Model is a Hustler. And it was bought around '76-'75. Would it take any kind of bearings or a certain kind? And where can I find a pair of trucks to fit?

- any bearings will work, and you can find them at walmart

- Q:I had found out bones reds are one of the most best bearings for the money, and lots of mates have them so I bought some bones red's from Trademe (the New Zealand version of ebay) and they were real and all. as soon as I got them I rode them all around. but after about a week they were worse than my abec 3's. So I changed Back to them. While I was at the skate park People were saying that bones reds just need wearing into. so I cleaned them by soaking them in turps then putting speed cream on them. I have been skating heaps this month. but still not beta...???So any advice or help of what im doing wrong would be appreciated

- Thats strange. I've had the same Bones bearings for years and they spin just as good as they ever did since the day i bought them. If it;s not to late I would say go back and exchange them or do like your friends said and try to break them in. But I can't imagine ever having to break in a good set of bearings...good luck

- Q:My car has recently started making extremely loud noises.. squeeking, squiling, grinding, and its all coming from the back of my car. This noise now continues while I drive, but at first it was just while I would press the brakes. Im trying to determine if this is my brakes going bad, or if it is my wheel bearing going bad. Anything would help thank you!

- If you jack the car up you can listen closely to the wheel bearings, and also try to rock the wheel by grabbing it at the 12 o'clock and 6 o'clock position, there should be barely any play. If you can wiggle more than a 1/2-1 mm then its likely the rear bearings have failed. If the bearings appear OK then remove the tire and try to remover the drum If the vehicle has disc brakes the pads will be exposed, if the discs are scored. grooved and damaged you will notice this immediately The disc should be almost polished smooth, with the disc brake pads held against the discs by the calipers, there should be at least 1/4 inch (6mm) of pad material. If you have drum brakes once you have removed the drum (remove cotter pin from cage and remove nut) inspect the shoes and brake hardware found inside, attached to the backing plate.

- Q:My 2000 4x4 Lifted Ford Excursion has a clicking noise when I am driving, on the front driver side. I can take my foot off the gas an it is still there no matter the speed. I am thinking it is a bad Hub/Bearing? How would I know for SURE that is what it is? Any tips on what to look for if I jack it up? Thanks.

- jack it up, grab the top and bottom of the tire and try to shift the tire around. If you can feel the tire give a little bit each time you push/pull on it, it's a bad bearing.

- Q:What is the reason the inner ring of some roller bearings are tapered, while others are flat-bored. What are some of the typical applications for roller bearings that are tapered on the inner ring?

- The tapered ones are made to take a side force. .

- Q:out of these three skateboard bearings which one is the fastest? bones swiss bearings,black panther swiss bearings,or black panther ceramic bearings

- Thats a good question. There all swiss so there going to be pretty close in speed. So I don't think it would matter which 1 you got for speed. But i would go with the most durible since there so close in speed. I'd try Bones because there Reds bearings are pretty good.

- Q:I have a pair of rx15 bauer roller blades and I need to get new wheels, bearings and spacers for them. I am a hockey player so I need some good wheels and bearings that will hold up, but I also don't want them to be expensive. If anyone has some good suggestions that would be great. I usually just buy the stock bearings and wheels, but they are getting expensive. Also is it worth it to get bigger wheels for the back two and smaller ones for the front?

- you can get any number of any parts that you want.

- Q:I have a Myrtle Longboard with Sector 9 wheels...right now my wheels spin for about 30 sec...how long would it spin approximately with bones reds?

- Free spin doesn't mean anything. You don't need new bearings unless yours are broken or rusted/seized. They won't make any difference. My Bones Reds spin for about 5 seconds.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HK 1716 Drawn Cup Needle Roller Bearings HK Series High Precision

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products