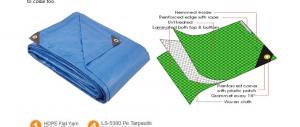

hight quliaty competitive waterproof dustproof sunproof pe tarps

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 300tons PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our company was set up in 2007,locatedin Dasunzi Village,Baishabu Town,Lanshan District ,Linyi City ,ShandongProvince,China.The factory occupies an area of 5,000 square meter and over 80workers.

Our factory manily produces PP and PE wovencloth,which has various colors ,such as one surface is blue ,the other silver, blue/white,double green,white /black, double white,double black ,double silver,blue/ orange etc.such as 80GSM,90GSM ,100GSM,110GSM,120GSM 160GSM and so on.various sizes ,such as2*3,3*4,4*5,5*6,6*8m,10*12m.

Allcan be produced in accordance with customers needs. The products can be widelyused as covers in cars trucks ,ships,field trips as well as factories,mines,and other enterprises.

Theycan also be used in field trip and used as simple tents .All products arewaterproof, sunproof ,anti-anging,anti-freezing,anti-corrosion.easy to fold andstand wear and tear ,etc.

Ourfactory has a large production capacity and a great varity of products, wewelcome all the customres ,both new and old ,to come to our company tonegotiable business.

- Q:Are olive nets suitable for organic olive orchards?

- Yes, olive nets are suitable for organic olive orchards. Olive nets are commonly used in organic farming practices to protect the olives from birds and pests, reducing the need for chemical pesticides. They are an effective and environmentally friendly solution for organic olive orchards.

- Q:How do olive nets prevent mold growth on olives?

- Olive nets prevent mold growth on olives by creating a physical barrier between the olives and the surrounding environment. This barrier helps to reduce moisture accumulation, which is a key factor in mold formation. Additionally, olive nets provide shade and improve air circulation around the olives, further inhibiting mold growth.

- Q:How do olive nets impact the overall cost of olive production?

- Olive nets can have a positive impact on the overall cost of olive production. By using nets, farmers can protect the olives from damage caused by birds, insects, or adverse weather conditions, leading to a higher yield and reduced losses. This results in increased profitability and a lower overall cost of production. Additionally, olive nets can also facilitate the collection of olives, making the harvesting process more efficient and reducing labor costs.

- Q:Do olive nets require any special installation techniques for densely planted groves?

- Yes, olive nets may require special installation techniques for densely planted groves. In densely planted groves, the proximity of trees can make it challenging to spread the nets evenly and ensure effective coverage. Special techniques such as using longer poles or enlisting additional help may be necessary to properly install olive nets in densely planted groves.

- Q:How do olive nets prevent olives from being damaged by pests?

- Olive nets prevent olives from being damaged by pests by acting as a physical barrier that covers the olive trees. This prevents pests such as birds and insects from directly accessing the olives, reducing the risk of damage or loss.

- Q:How do olive nets affect the production of olive tree sap?

- Olive nets play a significant role in enhancing the production of olive tree sap. These nets are used to cover the trees during the harvesting season, preventing the olives from falling to the ground and getting damaged. By providing a protective layer, olive nets enable the olives to remain intact on the tree branches, which ultimately leads to higher sap production. Additionally, these nets also facilitate the collection of sap by creating a controlled environment, allowing for efficient extraction methods. Therefore, the use of olive nets positively influences the production of olive tree sap by preserving the fruit and optimizing the extraction process.

- Q:Can olive nets be used for olive trees in regions with heavy rainfall?

- Yes, olive nets can be used for olive trees in regions with heavy rainfall. Olive nets are commonly used in olive groves to collect the falling olives during harvest season. While heavy rainfall can increase the moisture levels in the soil, which may affect the quality and quantity of olives, the nets can still be utilized to prevent the olives from getting damaged by falling onto the wet ground. Additionally, the nets can also offer protection against potential damage caused by strong winds and heavy rain.

- Q:What are the dimensions of a standard olive net?

- The dimensions of a standard olive net can vary depending on the manufacturer and specific use, but they typically range from 10 to 20 feet in width and 20 to 40 feet in length.

- Q:Are there any disadvantages of using olive nets?

- Yes, there are a few disadvantages of using olive nets. Firstly, olive nets can be quite expensive to purchase and install, especially for large olive groves. Additionally, these nets require regular maintenance and cleaning to prevent damage from debris or pests. They can also be labor-intensive to set up and remove, which may increase operational costs. Lastly, some farmers have reported that olive nets may cause uneven ripening of olives and hinder air circulation, potentially increasing the risk of fungal diseases.

- Q:How does an olive net affect the overall water usage in the olive grove?

- An olive net helps reduce overall water usage in an olive grove by preventing evaporation and retaining moisture in the soil.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

hight quliaty competitive waterproof dustproof sunproof pe tarps

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 300tons PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords