Highly purity ceramic fiber anti-Heat board STD6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Highly purity ceramic fiber anti-Heat board STD

High purity ceramic fiber board

General information of ceramic fiber board

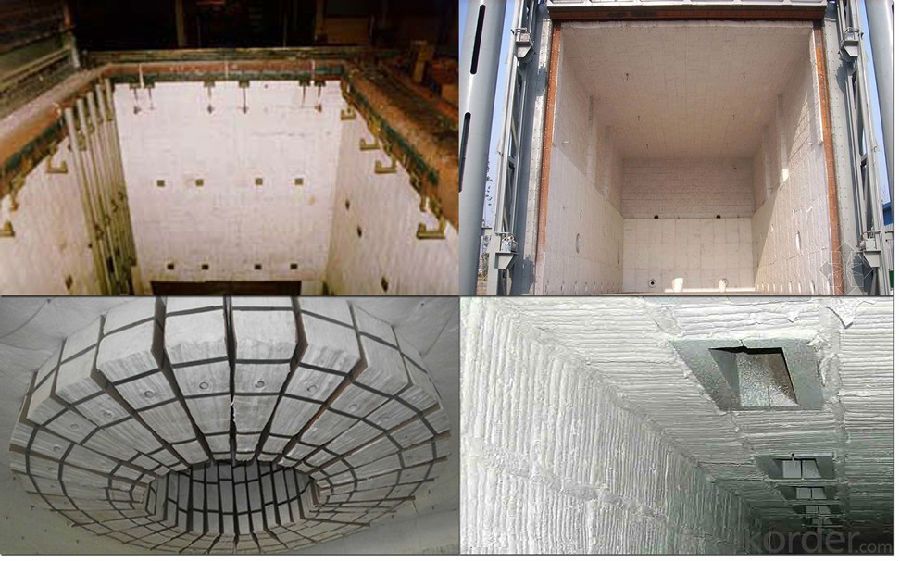

Cmax ceramic fiber board is made of high quality kaolin clay, centrifugal high purity alumina and silica or blowing process. It's no asbestos. Double side acupuncture for the board, with a lot of tensile strength or strong, easy to install.

Products are divided into standard, high pressure, HA and Hz, respectively, corresponding to the highest service temperature of 1000, 1100, 1200, and 1350

Characteristics of ceramic fiber board

Heat resistance

Light weight

Low thermal conductivity

Low heat storage

Thermal shock toughness

High tensile strength

Application of ceramic fiber board

Refractory fiber lining for petrochemical process heating furnace

Heat treatment furnace or intermittent (shuttle) kiln heat surface lining

General oven standby insulation

Heat sealing or kiln kiln car door

Electrical insulation

Ceramic fiber board

Common problem solutions

1. What products do you have?

We have all kinds of refractory bricks, refractory casting materials, mortar, cement, ceramic fiber products, etc..

Or you can browse our products to choose what you need.

2. How to control product quality?

With strict quality control system throughout the material selection and production process, we have the quality of refractory materials and ceramic fiber products to meet customer requirements.

From the selection of raw materials, the quality of our control to start. The quality certificate of the raw material is required, each batch of the products are to be tested in the use of the forward line. In the production process, the quality control by the workers, and then each piece of classification, and through the quality supervision and inspection.

3. Can you give me a brief introduction to the application of your product?

My company is mainly engaged in refractories in the steel, cement, glass, ceramics, petrochemical, electric power and other industries.

4. What information do you need if I need you?

In order to select the right products, we will provide us with information, such as the United States, technical data, order quantity, product application, etc..

If you have any questions, please contact us.

- Q:well i straightened it last night and it wos real straight for once and i was going to leave it out for school because usually i tie it up and everyone wants me to leave it down so i decided i would leave it straight and out and to be honest i was quite excited/happy, as an answer i've received before, i covered my hair in something silky and tied it up loosely, but when i woke up it was extremely wavy! i got soo upset and really angry, i had wasted my time straightening my hair and i've also burnt my hair by straightening it for too longi didnt know what to do i was really upset so as per usual i tied my hair up, and it made me really annoyedsoo what can i do to leave it straight overnight other then straighten it in the morning? (i wake up really late and barely have enough time to get ready aand i never have time to have breakfast aandit takes me about 1hour to straighten my whole hair!!)so what can i do to leave it straight?Thanks!!x

- Use a plastic bag corresponding to what sliced bread is supplied init may purely be reused like a a hundred instancesas quickly as comprehensive with the loaf, sell off out the remainder crumbs and that's in a place to pass backThe plastic bag works the comparable as plastic wrap(so the bread does not dry out immediately) Use a twist tie or a bag clip to close it.

- Q:I just got a new sewing machineI crochet hats, and other stuff and I was wondering if I can use my sewing machine to sew through the crocheted yarnWill the yarn get stuck in my sewing machine, or is it okay to sew through it? I just don't want to break my new sewing machine.

- alrighty well u can never go wrong with 'grinspoon', especially thier older stuff, remember that song peaches? well presidents of united states of america' still play great music if u want something heavier then look towards metallica' or 'Pantera' if your into more of the punk scene then aussi band frenzal rhomb' are what your looking for if u like foo fighters then u should enjoy shihad' there are too many more to list but here is a few regurgitator pearl jam system of a down smashing pumkins

- Q:I got a new hoodie this week that was too bigMy mom said it would shrink and I listened even though none of my clothes have ever shrunk(en?)So now I have a medium when I need a smallThis is my senior sweater so I'd prefer not to have it blanketing me or having to tie it in the back all the timeI've tried washing it in hot water and drying it three times and still no resultsI'd prefer not to have to wash it more, the inside is already losing it's softnessAny suggestions?

- Wash in hot water and rinse in ice cold waterThis will shrink the fiberRepeat until desired shapeJo Ann

- Q:BDU fabric options basically and I don't really know the difference between the options.

- there are maximum of variables that would make your equipment greater or much less of a good investmentI even have had a equipment for a pair years and that i'm very happy with themI distinctly propose you get a no legal duty quote, any respected photograph voltaic installation business enterprise would be prepared to try thisI actually have a 2 tale homestead with a pool (pump is one in all my great potential purchasers) in sunny CA and characteristic great orientation, and no coloration on the sectionI have been given a three.seventy 4 kw equipment (20 panels i think of) that fee $26K, I gained a $10K rebate from my application and a $2K fed tax credit (at the instant the tax credit on the comparable equipment is $7800) i became into projected to break inspite of my utilization in 7.2 years, it would desire to be faster in view that my city has raised expenses via 20% interior the previous 2 yearsThe equipment produces approximately ninety% of my summer season utilization and approximately 50% of my wintry climate utilization.

- Q:What is the feature of ceramic fiber gasket?

- 1)Continuous use temperature can reach 1000℃ while short time using temperature is up to 1260℃.2) It is highly resistant to acid-base corrosion and erosion of molten metal (eg. aluminum and zinc). 3).It is good in high temperature strength and thermal insulation properties (please refer to physical and chemical indicators.) 4) It is better in electricity insulation than glass fiber. 5) It is non-toxic, harmless and odourless.

- Q:I need it.thanks in advanceI'll be sure to give 10 points.

- You can goto any car store like pep boys or even walmart and get the refrigderant to add to your systemIt is easy but you MUST follow directions for your car or your risk blowing up your systemAsk around to see if you have a friend or friend of a friend who is a mechanic or has a mechanical experience to help youA typical charge at a garage if there isn't any problems for your system is usually around 200Weigh that against a blown system which will run around 1000

- Q:Within the past maybe 3 years or so we have been getting mold on your ceilingsIn some rooms more than othersIt is mainly along the molding and edge of the wall but sometimes it ventures into the middle of the ceilingSometimes it dripsWe dont know what is the cause of it and we're constantly wiping the ceilings downWe have been told it could be due to the insulation, so we took out the old and replaced it all and it still came backIf anybody knows why this could be happening as well as to get rid of it , for good, that would be extremely helpful!

- First,make sure that the insulation over your ceiling does not contain a vapor barrierA vapor barrier will be a kraft paper, plastic or perhaps aluminumUnlike your walls your want to allow humidity in your house escape through the atticIf the insulation is okay then it is likely that your attic is not properly ventedIn most cases you want air be be able to enter the attic via vents or opening in the soffits located along its perimeterDon't fill them with insulation! This air then should exhaust through roof vents, ridge vent or perhaps gable end ventsThis flow will exhaust the moisture from the houseWithout this ventilation the warm moist air from within your house will condense on the underside of the roof during cool weather (most commonly the north facing slope) and then can drip down onto your ceilingOne final suggestion, if your house is built over a crawlspace check it out and make sure that you are not sitting over ponded waterThe moisture from this water will make its way through your house undetected as humidity and exacerbate any ventilation problem you might have in the attic.

- Q:ive just bought some,there great to use but want to kno the history of them

- Because of their portability, it is likely these evolved very early onAfter all, weaving in many forms from basketry to warp weighted looms came into being in prehistoric timesSince most Neanderthals were nomadic or semi-nomadic seasonally, it makes sense that a weaving project that could be hand carried and worked on would have come early onSpinning fibers into yarns and using plant fibers began by doing finger and thigh spinning (where the fibers are held stationary in one hand and rolled up or down the legs of a seated person, not easy btw), but it is believed that weighted spindles, even those as simple as a flat rock cross tied with thigh spun yarns were among the earliest spinning devices that would have let travelers spin as they walked.

- Q:someone gave me several skeins of quot;virgin woolquot; fingering weight sock and sweater yarnit's relatively itchy and a plain grey colour, I wasn't sure what made it quot;virgin woolquot; and what I should use it for.

- look up the group anthrax

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Highly purity ceramic fiber anti-Heat board STD6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords