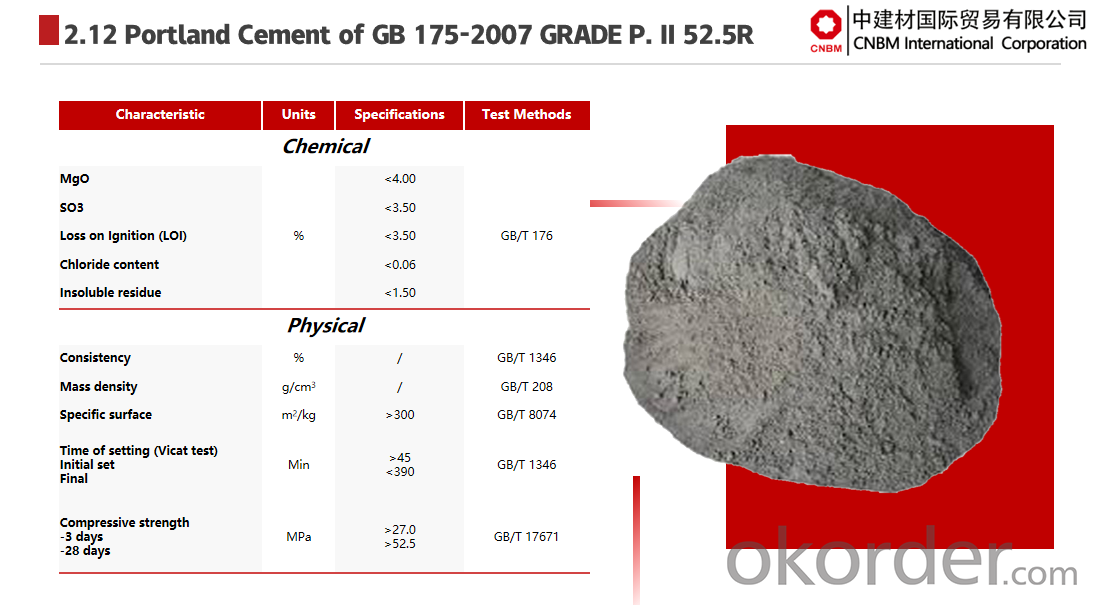

Highest quality for Portland cement of GB 175-2007 GRADE P. II 52.5R

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PORTLAND CEMENT

Portland cement is the most common type of cement in general use around the world, used as a basic ingredient of concrete, mortar, stucco, and most non-specialty grout.

It is a fine powder produced by heating materials in a kiln to form what is called clinker, grinding the clinker, and adding small amounts of other materials.

Several types of Portland cement are available with the most common being called ordinary Portland cement (OPC) which is grey in color, but a white Portland cement is also available.

Application

CNBM Cement can be used for all types of architectural or structural concrete construction. Such application as pre-cast panels and systems, cast-in-place, masonry units, tilt-up panel systems, roofing tiles, terrazzo floors, highway median barriers, tile grout, swimming pools, stucco, culture stone,colored masonry products, cement paints and coatings, and ornamental precast concrete items.

CNBM INTERNATIONAL CORPORATION (short for the Company) is a subsidiary of China National Building Material Group Co., Ltd. (short of CNBM Group). China National Building Material Group is a state owned enterprise under directly management of the State-owned Assets Supervision and Administration Commission of the State Council, and ranked 187 in the world's top 500 in 2019. China National Building Materials Group is the world's largest comprehensive building materials industry group, the world's leading new material developer and comprehensive service provider, and has the strongest scientific research strength in the field of building materials and non-metal new materials. CNBM INTERNATIONAL CORPORATION is a brand-new platform built by China National Building Materials Group that focuses on non-metallic materials trading.

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:TT and LC are both Okay.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q:The house was built in 1925 without foundation tile, over the years whatever was painted over the brick interior walls has bubbled because of the moisture that would have been diverted by an appropriate ditch around the foundation, or tiles to drain it, etc. Several of these bubbles are basketball in size, and there are cracks in many areas of the stucco-like stuff that chips off in large pieces. I want to patch it up, and repaint, what is that stuff called? It looks like cement when chipped off, is it joint compound? How should I go about this? Moisture problems have been aleviated, now I just need to fix the cosmetics.

- When you've got any moisture you desire a moisture sealer. If not that's even higher, makes it lot easier. Prime with zinnser primer tinted virtually the color of your paint. Then comply with with a LATEX PAINT making use of a thick nap curler. If you wish to make it ornamental, buy a sponge curler and use a second colour and position over most effective the skin of the block. It appears rather first-class and dresses it up alot. Good success!! You should utilize a latex paint. I painted block wall in basement that was once getting some moisture, and did use zinnser primer adopted with the aid of latex about 10 years ago and it looks as good in these days as the day I painted it!! So i do know for fact it can be performed.

- Q:i need home work help

- Cement is used to make concrete! 1part cement to 3 parts sand 2 parts water is one form of concrete! Pebbles and lime can also be added! After everything is mixed it can be made into many things! House foundations, Walls, Piers, supports for bridges, roads, buildings! You name it! Cement is a valuable resource!

- Q:The bottle on elmers rubber cement has a warning not to use if pregnant or contemplating being pregnant, and I am 5 weeks, what could the side effects be? I used it for aprox a half hour of time.

- How did your baby turn out? I'm 9 weeks and did something similar:(

- Q:Trivia question:: If trees are for humidity -- water is for moisture - what is cement for?

- Cement is for hardenng things togther.

- Q:So......I'm a little over my head here. Started taking down wallpaper and wouldn't you know it, there was layer, upon layer and then I accidentially started taking up the backing and came to cement. Have done what I could to salvage what I did, but have decided I'm going to use textured wallpaper over the existing. Do you think it'd be alright to paper right over and on the cement?

- concrete or cement is a porous surface and will not let the glue stick for the long haul. you need to paint the surface with a sealer before you began. a good sealer to use is dryloc. you can pick it up in any paint store or hardware store.

- Q:I have a ceramic tile floor that has cement board adhered to the top of it, with carpet glued to the cement board. I have removed the carpet, and now i want to remove the cement board to reveal the tile underneath. Any suggestions on how to removed the cement board?

- NOT GONNA HAPPEN,THE ONLY WAY TO REMOVE THE CEMENT IS BY FORCE AND WHEN FORCE IS ADDED THEN THE TILE GETS BROKE,UNFORTUNITLY WHO EVER PUT THE CEMENT ON THE TILE DIDN'T HAVE ALOT OF FORTHOUGHT AS TO WHAT IF YOU WANTED THE TILE BACK AT SOME POINTIN THE FUTURE

- Q:the house is from 1959. Before I bought it the owners re-landscaped without any consideration for water flow thus causing the basement to have seepage through the walls. I fixed the water flow issue (1.5 years dry) but now I have painted cement walls that have paint pushed out/peeling with a few visible cracks and wonderful mineral deposition. I really don't want to spend the time with the metal wire brush to strip the paint off so I would like to just use hydraulic cement over the whole wall and then use a water sealing paint over the top. Is this a good idea? other suggestions?

- That sounds more time consuming than just scraping off the peeling paint..... Here's 1 problem w/your approach, latex paint dries so fast that it actually creates a vacuum effect in doing so, which means that as it dries it'll pull off the surface anything that's not firmly attached, which is why prep work's so important to longevity. You won't immediately notice this happening, but w/the passage of time you'll be back to the peeling wall in spades. I've never heard of skim-coating w/hydraulic cement, but I've done plenty of patching plaster walls w/plaster of paris, what immediately comes to mind are the inherent problems w/working in a medium that sets up so quickly, I can't imagine how you'd get a whole wall covered looking even satisfactory (but I'm pretty picky, I figure when people are paying me I'm obliged to do a better job than they could've) w/out going insane in the process. I learned the trick to plaster, but I don't know the chemistry of hydraulic cement well enough to find a retardant for it. Anyways, I know prep-work sucks, but often it's just easiest to do it get it over with (start w/a stiff putty knife, by the way) rather than inventing a new process having to deal w/a long string of learning curves as you go. The first question that came to mind w/your question is have you ever skim-coated anything before so that you'd have even a vague idea of what you're getting yourself into potentially, but if you must create, than by all means go forth!

- Q:i have about 50 blocks to lay what knid of cement do you use what is the different between cement concretei have reddy mix that i use for making my rocks for my walk way but it has rocks in it i'm buling a 3 sided to put my grabage cans in so they don't have to be pretty i just want to keep the anamile out of the grabage in between there pick up each wk

- dont even bother with using mortar. -goto home depot or some other place and get a few tubes of construction adhesive the reads it will work on concrete. then paint it white or whatever color you want. Job done. Me? i woud use something loke exterior grade liquid nail.

- Q:I have some cement cracks and i was wondering how to fix it. any sugsetions?

- Cracks oftentimes do no longer restoration unquestionably or efficiently. the main suitable you may commonly do is seal them with caulk made for the activity (see your interior reach ironmongery shop). you may attempt to possibly escalate the cracks to a million extensive and prepare an epoxy bonding agent and a competent non-decrease grout to the crack to fill them in. however the main suitable ingredient to do to repair severe cracks is to jackhammer out the undesirable part of concrete, make optimistic the backside is compacted decrease than the section, and re-pour the concrete.

- Q:The molars are the ones that hurt, my braces dont hurt as much now. I can't bite down on anything because of the ketac cement they placed on my rigth and left top molar. Is this normal, will the pain ever go away so that I can chew my food. I can't chew on anything. I got my braces on a Friday and it's Tuesday and the cement still hurts.

- I had cement put on molars too, to stop top and bottom brackets clashing. Are you definitely sure it's the cement which hurts, because it's not meant to? And chewing, despite feeling no pain, will be quite hard, that won't go away until the cement is removed. Edit: Not to sound a little big-headed, but I think it's purely because the brace is doing its work. Your back teeth, molars especially, hurt a lot longer than the other teeth. I've had top and bottom braces, and in both instances, the back, bigger teeth have hurt for a good week longer than the rest. I'd advise you sit it out till this Sunday. If the pain continues, or hasn't softened, I'd seek help then. But I have honestly found that big back teeth hurt especially more.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Highest quality for Portland cement of GB 175-2007 GRADE P. II 52.5R

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords