high temperature resistance bio-soluble fiber board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

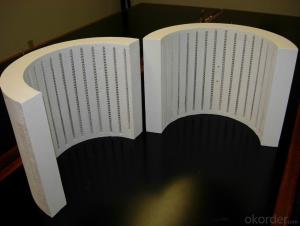

Product Image:

Product Description & Application:

Bio-soluble ceramic fiber board

Bio-soluble ceramic fiber board is board-shape high temperature resistant products which compose of undirectional soluble fibers blended with a spot of organic viscose.

Application:

Refractory and thermal insulation for industrial furnace;

Thermal insulation materials for equipments in the thermal power and heating system;

Refractory, thermal insulation, sound absorbing, fireproof in the building area.

Product Capability:

New type, low-carbon, energy-saving; environmental protection, no pollution, no carcinogenic material was included;

Good thermal stability, unaffected by thermal shock;

Block infra-red radiation, good corrosion resistance;

Biogradable, industrial wastes do not have to deal with.

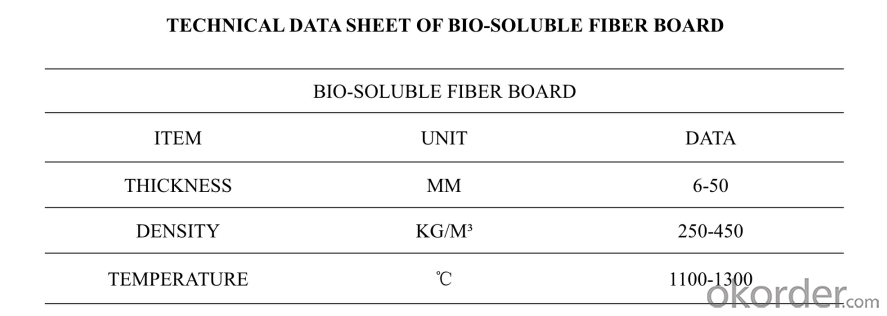

Data Sheet:

Bio-soluble Fiber Products:

This new type of refractory material is in comply with the rules which declared by the EU that hazardous material is fobidden or limited to be used (EU/EC) declaration).It can be resolved in biological body,contains no carcinogens and harmless to human body.

- Q:The characteristics of ceramic fiber paper

- 1, high strength tear resistant 2, high flexibility 3, low slag ball content 4, accurate thickness 5, thermal shock 6, very low thermal conductivity

- Q:Can a series of ceramic fiber products be used in combination?

- Industrial furnace insulation backing: suitable for all types of industrial furnace (annular furnace, trolley furnace, pit furnace, furnace donburi etc.)Materials: ceramic fiber blanket, ceramic fiber module, ceramic fiber module.

- Q:Who can help me introduce the principle of vacuum forming of ceramic fiber board? Thank you very much.

- Features: excellent chemical stability, excellent thermal stability, excellent tensile strength, low thermal conductivity, low thermal capacity, excellent sound absorption and noise reduction performance. Typical applications: aerospace, steel, petrochemical high temperature insulation; military road insulation; electrical components insulation; fire protection; high temperature gasket; modules, folding blocks of raw materials. Three. Ceramic fiber felt products: ceramic fiber vacuum forming felt is made of ceramic fiber cotton produced by resistance furnace injection molding. It is processed by vacuum forming process. It is a lightweight, flexible refractory fiber insulation material, made of a combination of high purity refractory oxides and organic binders. In addition to the excellent properties of bulk ceramic fiber cotton, the ceramic fiber vacuum forming felt has good strength and elasticity, and is a versatile product. Product characteristics: high strength, long service life; low heat capacity, low heat conductivity; non brittle material, toughness; size precision, good flatness; cutting easy installation, convenient construction; excellent anti erosion properties; continuous production, fiber distribution, stable performance; excellent acoustic noise performance.

- Q:What is the difference between the national standards for ceramic fiber products and ordinary aluminium silicate?

- Ceramic fiber products (aluminum silicate fiber products) in recent years, ceramic fiber products (aluminum silicate fiber products) in the application of high temperature sintering furnace expanding, ceramic fiber products (aluminum silicate fiber products) refractory felt and blanket products, the highest use temperature up to 1649 DEG C. Ceramic fiber products (aluminum silicate fiber products) to heat insulation effect is good, easy to use, especially small heat storage characteristics, widely used in various kilns, greatly demonstrated high energy efficiency. Ceramic fiber products (aluminum silicate fiber products) (1) ceramic fiber products (aluminum silicate fiber products) varieties and properties of ceramic fiber products (aluminum silicate fiber products) is the most important indicator of fiber diameter and thermal stability. Al2O3SiO2 fiber is commonly used in ceramic industry. It is divided into different application range according to the content of Al2O3, and Cr2O3 material is introduced into it to improve its refractory and oxidation resistance.

- Q:At present, the field of ceramic fiber, what is the latest development of technology or products?

- New product -- soluble ceramic fiber blanket. Ten years ago have been produced, but not up, from the beginning of 2015, Japan, Europe and other countries on the ceramic fiber products safety index is getting higher, the soluble ceramic fiber is also hot again, also with the help of a power plant thermal ceramic dragon pipe insulation insulation with 600 DEG 30mm thick aluminum silicate fiber blanket. The trial production of a batch of 20 tons of soluble ceramic fiber blanket.

- Q:How to choose the right ceramic fiber and aluminum silicate products?

- 2, depending on the use of the environment to chooseElectric furnace environment is a constant temperature environment, according to (1) to solve just fine.Gas environmental temperature insulation needs to upgrade a product grade to do insulation, such as gas furnace heating temperature of 1000 degrees, you need to choose 1260 high purity ceramic fiber aluminum silicate fiber to do insulation.The fuel / coal environment belongs to the bad angry environment, insulation material need to raise two grade level or higher to do insulation, such as pulverized coal heating furnace temperature, need to choose 1400 high alumina ceramic fiber aluminum silicate fiber or 1400 zirconium based ceramic fiber aluminum silicate fiber, to do heat preservation

- Q:What is ceramic fiber paper?

- The use of ceramic fiber paper, at 300 degrees Celsius (about) gradually ablate.

- Q:Refractory ceramics and other refractory materials manufacturing is a big industry?

- Also belong to the building materials industry, glass industry and other industries, are Rong Sheng refractories industry ah.

- Q:What is ceramic fiber?

- 1, ceramic fiber is a fibrous lightweight refractory material, has the advantages of light weight, high temperature resistance, good thermal stability, low thermal conductivity, specific heat and resistance to mechanical vibration, and thus in machinery, metallurgy, petroleum, ceramics, glass, electronics and other industries have been widely used.2, ceramic fiber products is a good refractory. The utility model has the advantages of light weight, high temperature resistance, small heat capacity, good insulation and heat insulation performance, good high-temperature heat insulation performance, no toxicity, etc..3, light quality, good heat insulation performance, good thermal stability, good chemical stability, easy processing and convenient construction. It is neither wear-resistant nor collision resistant, can not resist the erosion of high-speed airflow, and can not resist the erosion of molten slag.

- Q:What is the process of producing ceramic fiber mats?

- Mifso-12 ceramic fiber pad is Xin Xing sealing material factory is composed of ceramic fiber products through precise cutting, punching, die stamping process (part of the product after ultra high pressure adhesive bonding) produced.Can be customized by users to produce sizes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

high temperature resistance bio-soluble fiber board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords