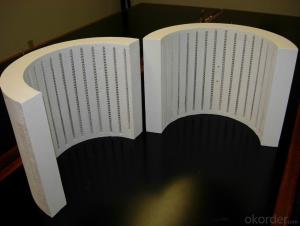

Tube Shaped Ceramic Fiber Heaters Used in Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

We use the imported High purified raw material to produce the tube heater, and the heater will be installed by different ways as customer required. The box continuous working temperature is 0-1200℃,it only needs 12 minutes the temperature can reach to 1000℃

Application:

Various electric heating furnaces

Smallest laboratory furnace, largest production furnace

Pipe heating

Advantage:

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

◆Low light

◆Precise size

◆Short heating time

◆Easy installation

◆Low dust

◆Energy saving

◆Long service life

Data sheet

FURNACE INNER SIZE(D×W×H) | Voltage(V) | Power(W) | Service Temp(℃) |

φ25×152 | 120 | 420 | 0~1200 |

φ36×334 | 220 | 1500 | 0~1200 |

φ36×512 | 220 | 2400 | 0~1200 |

φ50×200 | 110 | 1000 | 0~1200 |

φ60×400 | 220 | 2000 | 0~1200 |

φ70×520 | 110 | 800 | 0~1200 |

φ80×400 | 220 | 1500 | 0~1200 |

φ160×500 | 380 | 6000 | 0~1200 |

φ240×480 | 380 | 6000 | 0~1200 |

φ90×280 | 220 | 2000 | 0~1200 |

φ100×500 | 220 | 2400 | 0~1200 |

φ120×420 | 220 | 3000 | 0~1200 |

φ190×570 | 380 | 8000 | 0~1200 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

--------What is the use of ceramic fiber heaters?

The ceramic fiber heaters will be used in various electric heating furnaces,

smallest laboratory furnace, largest production furnace, pipe heating etc

---------What type of ceramic fiber heaters we can produce?

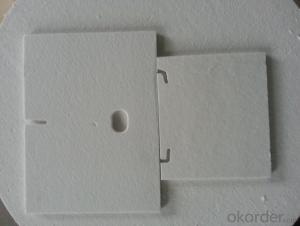

1. Flat panel

2. Half tube

3. Round tube

4. Box shape

5. Customers required shapes

----------what advantages of ceramic fiber heaters?

1. Precise size

2. Short heating time

3. Easy installation

4. Low dust

5. Energy saving

6. Long service life

7. Low thermal conductivity

8. High tensile strength

- Q:Definition of ceramic fiber

- 1. Definition of ceramic fiber:Ceramic fiber is a fibrous lightweight refractory.2, ceramic fiber expansion:Ceramic fiber, also known as aluminum silicate fiber, is the main component of refractory fiber!HLGX ceramic fiber is the refractory material with the lowest thermal conductivity and the best heat insulation and energy saving effect except the nanometer insulation material. The utility model has the advantages of light weight, high temperature resistance, good heat insulation effect, convenient construction, etc., and is a lining material of high quality industrial furnaces. Ji'nan dragon hot Ceramic Co., Ltd. has HLGX ceramic fiber module, HLGX ceramic fiber blanket and other ceramic fiber products widely used in kiln insulation project, high temperature equipment, pipe insulation.3. The origin of ceramic fiber appellation:First of all we want to know the origin and development of ceramic fiber, ceramic fiber first appeared in 1941, the United States Babu Hancock. Cox Newell company with natural kaolin by the arc furnace melt blown fiber. In 1950s, the ceramic fiber was put into industrialized production. In 60s, a variety of products were developed and used as lining for industrial furnaces.Thus, we know that ceramic fiber originated in the United States, and its name "Ceramic Fiber", literally translated literally "Ceramic - ceramic, Fiber - fiber, combination is" ceramic fiber".

- Q:Who can help me introduce the principle of vacuum forming of ceramic fiber board? Thank you very much.

- Features: excellent chemical stability, excellent thermal stability, excellent tensile strength, low thermal conductivity, low thermal capacity, excellent sound absorption and noise reduction performance. Typical applications: aerospace, steel, petrochemical high temperature insulation; military road insulation; electrical components insulation; fire protection; high temperature gasket; modules, folding blocks of raw materials. Three. Ceramic fiber felt products: ceramic fiber vacuum forming felt is made of ceramic fiber cotton produced by resistance furnace injection molding. It is processed by vacuum forming process. It is a lightweight, flexible refractory fiber insulation material, made of a combination of high purity refractory oxides and organic binders. In addition to the excellent properties of bulk ceramic fiber cotton, the ceramic fiber vacuum forming felt has good strength and elasticity, and is a versatile product. Product characteristics: high strength, long service life; low heat capacity, low heat conductivity; non brittle material, toughness; size precision, good flatness; cutting easy installation, convenient construction; excellent anti erosion properties; continuous production, fiber distribution, stable performance; excellent acoustic noise performance.

- Q:Which expert to help, urgent?! Thank you, 20Is the type of refractory material, shaped like cotton mattress like, but not really cotton, is some ore and some artificial material is made into the refractory with high temperature of one thousand degrees, will not change the kind of.

- Aluminium silicate refractory fiber cotton custom HS Code: 68061000.9068129900 refractory fiber cotton (containing asbestos)84748090 aluminium silicate refractory fiber cotton and its product line equipment

- Q:What is the difference between the national standards for ceramic fiber products and ordinary aluminium silicate?

- Generally high alumina content, iron oxide and other impurities of low fiber products are pure white, the introduction of chromium oxide fiber is sold with milk yellow tone color. The average diameter of ceramic fiber products (aluminium silicate fiber products) is 22 - 33 microns. High fiber, small density, low thermal conductivity, high temperature. If the fiber is coarse and dense, the use is not satisfactory. The thermal stability index of ceramic fiber products (aluminum silicate fiber products) is more important. The range of Al2O3SiO2 fiber contraction in various products of 1260 C line is 35 - 88%. The amount of shrinkage is also directly related to thermal stability. Ceramic fiber products (aluminum silicate fiber products) as ceramic fiber products (aluminum silicate fiber products) with low thermal conductivity, low density, light weight, light steel frame are used in the design and construction of kilns supporting structure, so that the development of ceramic kiln kiln into the "lightweight" era. The fiber has small heat storage and is suitable for quick heating and cooling firing.

- Q:Brief introduction of ceramic fiber cloth

- Application range of ceramic fiber cloth:All kinds of kilns, high temperature pipes and containers insulation;Furnace door, valve, flange sealing, fire door and fireproof rolling curtain material, high temperature door, sensitive curtain;Insulation of engine and instrument, fireproof cable coating material, high temperature fireproof material;Material for heat insulation covering, high temperature expansion joint packing, flue lining;High temperature resistant labor protection products, fire retardant clothing, high temperature filtration, sound absorption and other application areas instead of asbestos.

- Q:What is the use of ceramic fiber paper?

- 3) good high temperature strength and heat insulation performance (refer to physical and chemical indexes). 4) having a higher level of electrical insulation and high temperature electrical insulation than glass fibers. 5) non-toxic, harmless and odorless.

- Q:Refractory ceramics and other refractory materials manufacturing is a big industry?

- Inorganic refractory: CeramicHeavy industries (of fire furnaces)There are also organic polymers: halogen and halogen free construction"Ceramic fiber materials are generally used in heat insulation places, and can be used in all high temperature industries.

- Q:What is the process of producing ceramic fiber mats?

- Mifso-12 ceramic fiber pad is Xin Xing sealing material factory is composed of ceramic fiber products through precise cutting, punching, die stamping process (part of the product after ultra high pressure adhesive bonding) produced.Can be customized by users to produce sizes.

- Q:What brand of ceramic fiber products is best?

- Ceramic fiber, ceramic fiber, aluminum silicate fiber, its variety of products, the main products include ceramic fiber blanket (aluminum silicate blanket), ceramic fiber module (aluminum silicate module), ceramic fiber board (aluminum silicate), ceramic fiber paper (paper / aluminum silicate refractory fibre paper), ceramics (aluminum silicate fiber felt mat), ceramic fiber, ceramic fiber, ceramic fiber rope etc..The quality of the above products can be highlighted from two aspects:1, large-scale production2, the application of advanced technology3, brand awareness of the high and low

- Q:Slag ball content of ceramic fiber material?

- Slag ball content of ceramic fiber material?The content of 0.25mm foreign size > slag ball control in less than 5%, while domestic due to fiber manufacturing technology limit, content of slag ball control in less than 15%[1], which is nearly 1/8 fiber products in slag ball content twice as high than abroad. Therefore, in determining the bulk density of ceramic fiber products, we should give full consideration to the amount of slag ball.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tube Shaped Ceramic Fiber Heaters Used in Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords