High Strength Industrial PVC/PU Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Strength Industrial PVC/PU Conveyor Belt

PVC Conveyor Belt

PVC conveyor belt has good elasticity ,not easy to be deformed . It is widely used in good , tobacco , logistics , packaging and other industries . Applicable to coal mine underground transportation ,also can be used in metallurgy ,chemical idustry material handling .

Application

Widely used in Logistics and airports, food processing industry, tobacco industry, and other industry such as wood, marble and stone, textile, sports automobile and so on.

Features:

1. Good physical performance and wide range application

2. Anti-static and resistant to cutting

3. Hardness: 35-85 Shore A, Normal: 65-75 Shore A

4. Working temperature: -10C-80C

Colors:

Red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness:

PVC (1~7mm) PU (0.8~4mm)

Appearance:

flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages:

PVC: economical and practical, technology is mature. Non-toxic, odorless, environmentally friendly.

PU: abrasion resistant and corrosion.

Subsequent machining technology:

it can add baffle, skirt, sponge, guide bar and etc.

Packaging & Shipping

1.Free for samples, Door-to-Door.

2. By Air or by Sea for batch goods, Airport/ Port receiving.

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time:Based on customers' quantity. In general,25 days for batch goods.

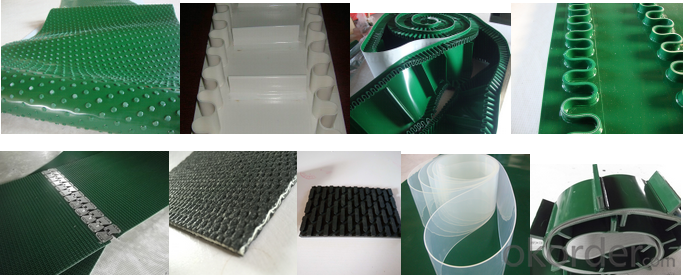

Product photos:

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products based on your requirements.It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1)All raw material we used are environmental-friendly;

2)Skilful workers care every details in handling the producing and packing processes;

3)Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance payment before shipment.

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q:Do olive nets require regular maintenance?

- Yes, olive nets do require regular maintenance. They need to be cleaned and inspected regularly to remove debris, prevent blockages, and ensure their effectiveness in protecting the olives from pests and birds. Additionally, any damages or tears should be repaired promptly to maintain the integrity of the net.

- Q:How do you prevent olive nets from causing damage to nearby structures or buildings?

- To prevent olive nets from causing damage to nearby structures or buildings, proper installation and maintenance are essential. Firstly, ensure that the nets are securely fastened and properly tensioned over the olive trees, so that they do not sag or touch any neighboring structures. Regularly inspect the nets for any tears, holes, or loose areas, and promptly repair or replace them to prevent olives from falling through or the nets from becoming dislodged. Additionally, it may be beneficial to create a buffer zone or install protective barriers between the olive trees and nearby structures to provide an extra layer of protection.

- Q:Can olive nets be used for olive tree nutrient management?

- No, olive nets are primarily used for harvesting olives and protecting them from birds, rather than for nutrient management of olive trees. Nutrient management involves the application of fertilizers and other practices to ensure optimal nutrient levels for tree growth and fruit production.

- Q:How do olive nets help in harvesting olives?

- Olive nets help in harvesting olives by providing a convenient and efficient way to collect the fallen fruits from the trees. These nets are spread beneath the olive trees to catch the olives as they naturally detach from the branches during the harvesting process. This prevents the olives from falling onto the ground, reducing potential damage and ensuring a higher yield. Additionally, olive nets simplify the collection process, making it easier to gather the olives and transport them for further processing.

- Q:Are olive nets flame retardant?

- No, olive nets are not typically flame retardant.

- Q:What are the main defects of common plastic products?

- Plastic products: mainly due to insufficient feeding, the melt filling flow is bad, too much inflation and bad exhaust causes to fill the cavity with plastic products shape incomplete or multi cavity individual cavity filled with.Dimensional instability: mainly due to poor strength of the die, poor precision, unstable injection molding machine and unstable forming conditions, the size of plastic products is unstable.Bubble: residual gas in plastic products due to melt inflated excessive or bad exhaust, and a small hole or clusters (note and vacuum bubble difference).Collapse (dent) or vacuum bubble: due to poor packing, poor cooling of plastic products, uneven wall thickness and high shrinkage of plastics.Flying too large: due to poor mold, the gap is too large, plastic flow is too good, too much feeding, plastic products along the edge of the thin thin wings.

- Q:Can olive nets be used in both traditional and modern olive groves?

- Yes, olive nets can be used in both traditional and modern olive groves. Olive nets are a versatile and practical tool for harvesting olives, regardless of the cultivation practices used in the grove. They can be easily installed and removed, making them suitable for both traditional groves with manual harvesting methods and modern groves with mechanized harvesting techniques.

- Q:How do olive nets prevent damage from extreme temperature fluctuations?

- Olive nets help prevent damage from extreme temperature fluctuations by providing a protective layer over the olive trees, acting as a physical barrier. This layer helps to regulate temperature by reducing the amount of direct sunlight reaching the trees, thus preventing overheating during hot periods. Additionally, the nets act as insulation, trapping heat during colder periods and protecting the trees from frost damage.

- Q:How does an olive net affect the overall fruit quality in the olive grove?

- An olive net can significantly improve the overall fruit quality in an olive grove. It acts as a protective barrier, preventing damage caused by wind, birds, and other pests. By keeping the olives sheltered, the net helps maintain their integrity, reducing bruising and deterioration. This ultimately results in higher-quality olives that are less prone to spoilage or defects, ensuring a better yield and improved overall fruit quality in the olive grove.

- Q:What is the material of plastic bottles? Will plasticizers be produced?

- Plastic bottles are made of polyethylene or polypropylene and added a variety of organic solvents. Most of the beverage bottles are made of plastic. The two materials, polyethylene and polypropylene, are non-toxic and tasteless. They are used for filling drinks and so on. They are very safe for the human body. But once the polyethylene is subjected to high temperature or acid corrosion, it dissolves slowly and releases organic solvents, which can cause harm to the human body.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Strength Industrial PVC/PU Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords