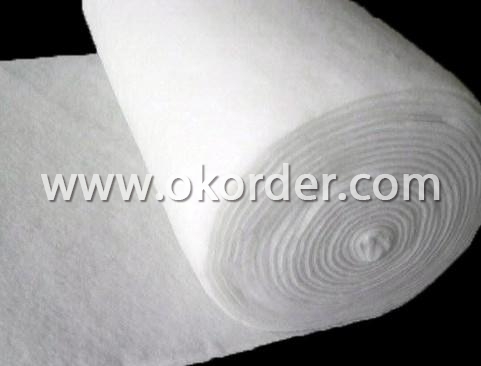

High Quality Nonwoven Geotextile

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000m2 m²

- Supply Capability:

- 30 million M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Nonwoven Geotextile:

Good flexibility, permeability, filtration, separation and easy for construction.

Geotextile has excellent permeability, acquired, durability, which can be widely used in railway, highway, movement hall, Dams, hydraulic structures, hence hole, coastal shoal, reclamation, environmental protection and other projects. The main products are Synthetic staple fibers needle punched non woven geotextiles, we can produce with PET original and recylced material.

Specification of Nonwoven Geotextile:

Technical specification of filament spunbond needle punched geotextile in PP and PET material.

|

Item |

Value | |||||||||

|

1 |

Breaking strength |

4.5 |

7.5 |

10 |

15 |

20 |

25 |

30 |

40 |

50 |

|

2 |

Elongation at break |

40~80 | ||||||||

|

3 |

CBR Mullen Burst Strength KN≥ |

0.8 |

1.6 |

1.9 |

2.9 |

3.9 |

5.3 |

6.4 |

7.9 |

8.5 |

|

4 |

Tear strength/KN |

0.14 |

0.21 |

0.28 |

0.42 |

0.56 |

0.70 |

0.82 |

1.10 |

1.25 |

|

5 |

Sieve Size O90mm |

0.05~0.20 | ||||||||

|

6 |

Vertical Permeability Coefficient cm/s |

K×(10ˉ1~10ˉ3),k=1.0~09.9 | ||||||||

|

7 |

Thickness/mm |

0.8 |

1.2 |

1.6 |

2.2 |

2.8 |

3.4 |

4.2 |

5.5 |

6.8 |

|

8 |

Width Variation % |

-0.5 | ||||||||

|

9 |

Weight Variation % |

-5 | ||||||||

- Q:How is this set of water quotas? More

- Specializing in the production of geotechnical materials

- Q:Can geotextiles be used in landfill applications?

- Yes, geotextiles can be used in landfill applications. They are commonly used as a protective barrier in landfills to separate the waste material from the underlying soil. Geotextiles help in preventing the migration of fine particles, controlling erosion, improving drainage, and providing structural support in landfill liners and covers.

- Q:What is the use of the black network when the shop is paved?

- It is geogrid, can enhance the overall strength of the roadbed, from the role of tensile, mostly polyethylene materials.

- Q:How do geotextiles help with subgrade stabilization in road construction?

- Geotextiles help with subgrade stabilization in road construction by acting as a barrier, separating the subgrade soil from the overlying base and pavement layers. This prevents the mixing and contamination of different soil layers, enhancing the overall stability and strength of the road. Additionally, geotextiles improve drainage by allowing water to pass through, reducing the risk of water accumulation and subgrade saturation, which can lead to softening and failure of the road.

- Q:What are the environmental considerations of geotextiles?

- Geotextiles have several environmental considerations that need to be taken into account. Firstly, the production of geotextiles requires the use of energy and raw materials, which can contribute to greenhouse gas emissions and depletion of natural resources. Additionally, the disposal of geotextiles after their useful life can pose a challenge as they are not easily biodegradable and can contribute to waste accumulation in landfills. However, geotextiles can also offer environmental benefits such as increasing soil stability, reducing erosion, and promoting better water management, which can help mitigate some of these concerns. Therefore, careful consideration of the environmental impacts and proper end-of-life management of geotextiles is crucial to minimize their negative effects.

- Q:What are the advantages of using geotextiles in stormwater management?

- Geotextiles offer several advantages in stormwater management. Firstly, they act as a filter, preventing fine particles and pollutants from entering the stormwater system, thus improving water quality. Secondly, geotextiles provide erosion control by stabilizing soils and preventing soil erosion during heavy rainfall events. Additionally, these materials aid in water infiltration, allowing stormwater to be absorbed into the ground instead of overwhelming drainage systems. Lastly, geotextiles are cost-effective and easy to install, making them a practical and efficient solution for stormwater management.

- Q:What are the factors to consider when selecting a geotextile?

- When selecting a geotextile, there are several factors to consider. Firstly, the application or purpose of the geotextile is important. Different geotextiles are designed for specific functions such as filtration, separation, drainage, or reinforcement. Understanding the specific requirements of the project and matching them with the appropriate geotextile is crucial. Secondly, the site conditions need to be evaluated. Factors such as soil type, slope stability, groundwater levels, and expected loads or stresses should be considered. The geotextile should be able to withstand these conditions and provide the necessary performance. Thirdly, the durability and longevity of the geotextile should be assessed. Factors like UV resistance, resistance to chemicals or biological degradation, and the expected lifespan should be evaluated to ensure that the selected geotextile can withstand the anticipated environmental conditions. Additionally, the installation and maintenance requirements should be taken into account. Some geotextiles may require specialized equipment or techniques for installation, while others may need periodic monitoring or maintenance. Understanding these requirements is essential for a successful project. Lastly, cost-effectiveness is an important factor. While it is crucial to select a geotextile that meets the project requirements, it is also necessary to consider the associated costs. Evaluating the initial cost, as well as the long-term benefits and potential savings, helps in making an informed decision. In summary, the factors to consider when selecting a geotextile include the specific application, site conditions, durability, installation requirements, and cost-effectiveness.

- Q:How do geotextiles contribute to soil compaction control?

- Geotextiles contribute to soil compaction control by providing a barrier between the soil and any applied load or traffic. This helps distribute the load more evenly, reducing the pressure on the soil and minimizing compaction. Additionally, geotextiles can improve soil drainage, allowing excess water to flow away, which also helps prevent compaction.

- Q:How do geotextiles help with soil stabilization?

- Geotextiles help with soil stabilization by acting as a physical barrier that prevents soil erosion and the displacement of soil particles. They provide support to the soil, distribute load stresses, and improve the overall stability of the ground. Additionally, geotextiles promote water drainage and filtration while preventing the loss of fine soil particles, thereby enhancing soil quality and preventing erosion-induced damage.

- Q:Who knows geotextile, how to sew, the best video

- Where do you use it? Professional production geotextile manufacturers to answer,

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 2001 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% North America 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001; ISO14000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality Nonwoven Geotextile

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000m2 m²

- Supply Capability:

- 30 million M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords