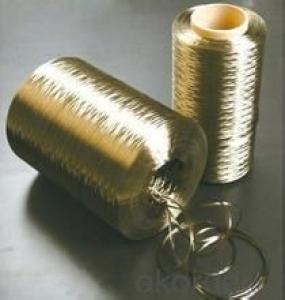

High Quality Basalt Assembled Roving with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

It is a Fiberglass roving produced by directly winding a certain number of individual fibers form the bushing without twist,it is coated with a silane-based size and is designed for reinforcing unsaturated polyester, epoxy,vinyl ester and phenolic resins. it is specially used to produce GRP pipes, pressure vessels, gratings and profiles and, when converted into woven roving, boats and chemical storage tanks, with filament winding, pultrusion and weaving process

Specifications

Assembled roving represent an untwisted strand, made up of several evenly strained complex yarns.

Rovings are manufactured according to Technical Specifications 5769-026-00204990-2005.

Assembled roving represent an untwisted strand, made up of several evenly strained complex yarns. Complex yarns for assembled roving are made of basalt crumb.

Example of assembled roving: BC11320W-76(64)

B – raw material – basalt crumb.

C –continuous yarn.

11 – nominal diameter of a simple yarn, μm.

320 – nominal linear density of roving, tex.

W – purpose of roving: W – for weaving.

76 – type of silane sizing.

64 – nominal linear density of a complex yarn, composing roving.

Field of application:

1. Manufature of basalt fabrics;

2. Manufacture of basalt plastics;

3. Manufacture of bodies of rotation: pipes for chemical, oil and gas industries, pressure relief pipes, tanks (made by winding) for storage and transportation of chemically active substances, waterm combustive-lubricating products.

4. For reinforcement of plastics and concrete.

5. In production of geotextile nets and canvases, serving for reinforcing of asphaltic concrete pavement, by improving durability and split-resistance.

FAQ:

1.Who will pay for the express cost ?

A: We can support you free samples ,but express cost will be paid by you .

2.How long is the delivery time?

A:within 10-15 days after receiving deposit.

- Q:Method for repairing water leakage of toilet without knocking brick.

- 1 Buddha plastic mud: It can replace the glass glue, completely solve the problem of Water Leakage mildew in wall corner and window corner. Metal, glass, cement, stone, tile can completely bonded into a whole. The invisibal waterproof liquid (seam leakage NEMESIS): the international most advanced waterproof materials, colorless and tasteless water and looks exactly the same. A simple rinse two times to solve the tile surface and the joint leakage and the surface color has no effect. The permanent waterproof effect is not removed! Dig into a great magic Water Leakage governance bathroom waterproof material or other room downstairs home! 3 bathroom water leakage solution set is plastic mud invisible waterproof liquid (seam leakage NEMESIS) suit

- Q:Is arbon fiber better than glass fiber reinforced plastic

- Lighter and more toughness.

- Q:How to make the lining of tank acid-proof and anticorrosion.

- If it is metal can, cleaning, descaling and brushing anticorrosion lacquer will be fine.

- Q:What is rippled glass?

- Opaque glass.

- Q:What kind of knife can used to cut glass wool cloth?

- You just need to cut off the big square. At first, you need to cut off the big square along border line and center line. Then you should cut off the two overlapping rectangles along the diagonal. At this moment, there are four right triangle which just can be put into a hollow square with its area just is equal to the small square, then you should put the small square into the hollow aquare.

- Q:grc fiberglass

- If grc was shaped by injection, glass fiber chopped yarn will be fine; if it was shaped by hands, alkali resistant fiber glass with mesh of 1cm * 1cm will be fine.

- Q:What does the basalt fiber do?

- According to its characteristics, it is a very wide range of industrial raw materials. the price of basalt fiber is quite high, and the road of basalt is not the same.

- Q:how to produce glass?reinforced?plastics grating

- Production technology, there are mainly three konds of glass?reinforced?plastics grating production process: Peciprocating filament winding process, continuous filament winding process and casting process. Reciprocating filament winding process(belongs to fixed-length method): In this process, the leaching glue tank with rotating mandrel reciprocate and the long glass silk with a certain angle works as auxiliary. Auxiliary angel (the winding angle) is controlled by the moving speed of leaching glue tank and the speed ratio of mandrel and translational motion of leaching glue tank is controlled by computerized electric machine. The layer number of twisting is gradually increased to meet the thickeness of design wall. After winding is completed, resin in products should be solidified and then form mandrel from glass reinforced tube. Continuous filament winding process (belongs to continuous method) The process is that pipe pass through a feeding station which is to supply resin presoak roving, chopped glass reinforced fiber, resin sand mixture. then pipe formed in the continuous progress of mandrel. Casting process (belongs to fixed-length method) In this process, chopped glass fiber reinforced materials and sand are put into the steel mould fixed in bearing, then unsaturated resin used as catalyst is added into one side of steel mould to dip reinforced materia. Under the effect of centrifugal force, the resin exchange fiber and filler in the air so as to create a nonporous compact composite material and a smooth, bright and clean pipe surface layer with rich resin. steel tubes start to curing under high temperature. Pipe produced in this way is also called glass reinforced plastic sand pipe. In the world, the number of manufacturers using reciprocating filament winding process to produce tube is more than that of the rest two production technology. One of the reasons is is that the former has a wider range of usage and its applicability is better.

- Q:What are the advantages of glass fiber reinforced plastic antennas? What's the difference between an ordinary antenna and an ordinary one?

- SMC, which is composed of SMC, unsaturated polyester resin, glass fiber roving, and other materials with special equipment by SMC forming unit made of sheet, and then by thickening, cut, put on metal mold by high pressure and high temperature curing made.

- Q:Definition of glass fiber reinforced plastic doors and windows

- The unsaturated resin is used as the subtrate material. it have many advantages such as sound insulation and so on. Glass?reinforced?plastics is also called glass fiber reinforced material with lightweight property. Glass?reinforced?plastics doors and windows use glass fiber twistless roving and fabric as reinforcement material. It is a new type of composite material developed abroad in early twentieth Century and can add other mineral filler.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Basalt Assembled Roving with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords