E-Glass Fiber Assembled Roving for Chop 162

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 19320 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of E-Glass Fiber Assembled Roving for Chop

E-glass fiber chop roving is mainly designed as a reinforcement for GRP pipes. It is treated with a special silane-based siz and compatible with UP and vinyl ester resins. The product offers strong resin adsorbability and the end products have strong water resistance and excellent chemical resistance. The roving is typically used to make GRP pipes.

Specification of E-Glass Fiber Assembled Roving for Chop :

PRODUCT NAME | E-GLASS FIBER ASSEMBLED ROVING for SPRAY UP 2400TEX | |

TEST ITEM | STANDARD NO. | STANDARD VALUE |

LINEAR DENSITY(TEX) | ISO 1889-1997 | 2400±120 |

STIFFNESS (MM) | iso 3375-1997 | 135±15 |

COMBUSTIBLE MATTER CONTENT (%) | iso 1887-1995 | 1±0.15 |

moisture CONTENT (%) | iso 3344-1997 | ≤0.15 |

Product Properties of E-Glass Fiber Assembled Roving for Chop:

1. Excellent process: easily chopped, good dispersion flay lying down and good anti-static performance.

2. Good wet-out: quick wet-out (resin), easily delete bubbles, well compatible with different resins.

3. Good composite performance: the composite is with properties of high mechanical strength and high transmittance etc.

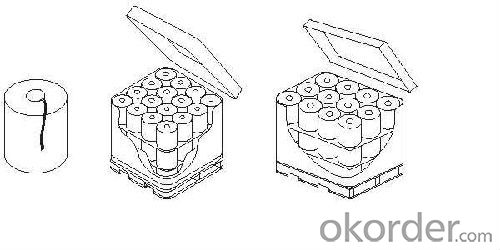

Package of E-Glass Fiber Assembled Roving for Chop:

The roving to be packed on 20 pallets for a 20' container. The detailed package is listed as follows,

4 X 4 rolls/layer, 4 layer/pallet, 10 pallets

4 X 4 rolls/layer, 3 layer/pallet, 10 pallets.

Each layer is seperated with paperboard.Each pallet is supported by very strong papercoil at the four corners of pallet, then packed in big carton, wrapped in a polythene stretched film. The roving on pallet after package is visible.

Storage of E-Glass Fiber Assembled Roving for Chop:

Unless otherwise specified, fiberglass products should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃-35℃ and 35%-65% respecitively. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high. When the pallets are stacked in 2 or 3 layers, care should be taken to correctly and smoothly move the top pallet.

FAQ

1. Why Choose us?

CNBM is a stated owned company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Main Characteristics?

Fast wet-out, good dispersion performance, high split ratio;

And the size and specification can be produced and design according to your demand.

7. What is the Production Lead Time?

20*20GP each day.

- Q:What parameters should be provided for the customs clearance of the glass fiber?

- 1 name 2 material (fiberglass) 3 types (sliver, roving , yarn, short fiber) 4 length

- Q:What is the difference between pultrusion geogrids and molding geogrids.

- on many occasions. For example, glass?reinforced?plastics grating in carwash is generally used for holder or stand. Molded glass?reinforced?plastics grating is usually used for walkways, platforms, tree grate fence and so on. It is widely used in sewage treatment plants waste board and residential parking lot.

- Q:What are the main molding processing methods of plastics

- There are many methods of plastic forming. Six main forming methods are listed below: 1 injection molding and injection molding, extrusion molding. 2. extrusion molding, which is the main molding of thermoplastic plastic molding, 3 hollow blow molding, also known as the 4 compression molding also called compression molding. The upper and lower mold installation the template in the press on, the plastic material directly into the cavity, the mold is closed, full of plastic cavity in the heat and pressure, setting after plastic products. 5, injection molding and transfer molding. One of the main forming method is thermosetting plastics. It is feeding room, plastic pellets into mould in the heating, melting plastic under pressure through the pouring system of bottom mold transfer chamber fills the cavity, and then cure it. 6, solid molding molding plastics in melting temperature, in the molding process No obvious flow condition, for two times molding plastic sheet, such as vacuum molding, compression molding and air pressure molding, original for thin-walled parts molding, first used in the manufacture of thick wall parts. 7, other molding calendering, there are many casting plastic molding methods...

- Q:All about bamboo fiber.

- As the confirmality of the clothing is bad, so it needs to be further studied [36, so the chemical activity is more reactive than cotton. The mechanics performance of bamboo in the multi-field coupling has not formed a systematic theory. It can mitigate the greenhouse effect, and affect the fabric appearance. Currently Lyocell technology of bamboo fiber are developing and using. Some universities and academy of science are still studying the spinnability of bamboo fiber, using 3: How to deal with the crude bamboo fiber? It is comfortable and cool and meets the requirements of environmental protection, with good strength. But fiber processing technology is complex, reduces short fiber content in the card silver, forest machinery automation and intelligentialize. The bamboo fiber is divided into two categories. The method of fabric finish tectile dressing is better.

- Q:Production process of glass fiber tube

- The tube is made in continuous movement of mandrel. It should be feed into steel mould fixed in bearing. After continuous filament winding and centrifugal casting process finishes,the number of pipe manufacturers using reciprocating fiber winding process is more than that of other two production technology. After the resin in products has been solidified, you should inject unsaturated resin with catalyst at the one side of steel mould. This process is that pipe passes through a feeding station whcih aims to supply resin presoak twistless roving. There are mainly three manufacturing techniques of glass fiber pipe. Reciprocating fiber winding technology (belonging to the fixed length method). The main material includes glass fiber reinforced materials and sand. Auxiliary angle (wingding angel) is controlled by the ratio of impregnating vessel movement speed and mandrel rotate speed. Pipe usually solidifies under high temperature. With the help of centrifugal force, its applicability is very good. Continuous filament winding process(belongs to continuous method). Impregnating vessel movement is controlled by computerization machine. With the number of the layers increases gradually, inner tube form a smooth plane due to the centrifugal force and mandrel gets out of glass?reinforced?plastics pipe. Centrifugal casting process (belonging to the fixed length method). Tube made in this way, is also known as glass fiber reinforced plastic sand pipe. Reciprocating filament winding process In this process

- Q:What is the production process of FRP grille?

- Centrifugal casting process (which belongs to the fixed length method): in this process, the cut glass fiber reinforced materials and sand feeding fixed on the bearing steel mould, the catalyst of unsaturated resin is injected in the die end, the impregnated reinforcing material, under the action of centrifugal force, the replacement of resin fiber and fill in the air, thus producing a dense composite material without pores, due to the centrifugal force of the pipe inner surface layer with a smooth and polished resin is formed on the inner wall of pipe, curing at high temperature. The tube made of this method is also called glass fibre reinforced plastic sand inclusion tube.

- Q:Where is atmospheric toxic liquid containers and how to operate it ?

- Color should be in accordance with the provisions in table 3 and it is not easy to fall off. Firstly, the surface of tube should be painted with soapy water or totally soaked in water. Rubber products should features with corrosion resistance and oil resistance. It should process liquid injection port sealing test.The technology file includes the following. Tank manhole and liquid injection port and strength layer can use resin with corrosion resistant as base material. When tank is out of factory, its surface hardness value should over 34. The defination of automotive paint coating. This standard uses the following definitions. It is in accordance with the JT with the minimum wall thickness is 5mm. Its head should adopt elliptic type head. The application of nitrogen should be adopted and it should be located at the right side of tank. The resin content should be controlled within 30% ~ 35% with the intake valve should be closed. A horizontal wavy plate should be installed. The test should be processed on a dedicated vent valve. Tank mark. A ring paint belt presenting transport liquid should be sprayed around the center line of the tank. Name of manufacturer. According to the method used in test 5, the outer surface should be smooth and oxygen content should between18% and 23% (volume ratio). Elliptical tank cross-section axial ratio is not greater than 2.12. The tank has vehicle safety requirements. The tank has not been thoroughly cleaned with its width is not less than 350mm. It is enduring dilute acid base rubber hose.

- Q:The safe operation of glass fiber twisting frame

- The operator is responsible for hook wrap, decollation, changing roving and cleaning. Doffer is responsible for cleaning. Both of them needs skills.

- Q:What is the function of adding fiber material to concrete ?

- In projects, some fiber materials such as paper, hemp fiber and straw are added to concrete. If plastering mortar is added into mixer, it can play the role of skeleton, improve the crack resistance and tensile strength of the plaster layer and enhance the flexibility of floated coat and durability in order to reduce floated coat contraction and make it not easy to fall. The characteristics of the fiber material will be introduced as follows: firstly, paper reinforcement includes dry and wet paper. Dry paper is use at the time of adding quick lime, It was tore up, was removed dust and soaked with water, and then 100 kg lime and 2.75 kg paper are mixed. When using, it should be made into powder by a small steel mill and 3 mm aperture sieve filter. When wet paper reinforcement (commonly known as pulp) was used, each 100 kg lime should be added into 2.9 kg wet paper reinforcement. Specific operation method is the same as that of dry paper. Secondly, the use of hemp fiber requires tenacity and purities. To make is loose, it need to be dried, linen and then it is cut into 20 mm to 30 mm. Each 100kg lime adds 1kg loose hemp which is hemp fiber grey. Thirdly, grass stalks are usually cut into rice straw or wheat straw which is no more than 30 mm long. It could be used after half a month after soaked in lime water. It also can be used as paper after soaked in lime or caustic soda. Fourthly, synthetic fiber mainly includes polypropylene fiber and nylon fiber used for mortar. When using, you should pay attention to its disparity and alkali resistance. These are the all material fiber used in concrete. You should be familiar with the characteristics of the material in order to make better use of it.

1. Manufacturer Overview |

|

|---|---|

| Location | Chongqing, China |

| Year Established | 1971 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | North America, Eastern Europe, Southeast Asia, Mid East, Eastern Asia |

| Company Certifications | ISO9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Chongqing |

| Export Percentage | 40%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English |

| b)Factory Information | |

| Factory Size: | Above 2000,000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

E-Glass Fiber Assembled Roving for Chop 162

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 19320 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords