HIGH QUALITY C-GLASS CLOTH FOR LAMINATING

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

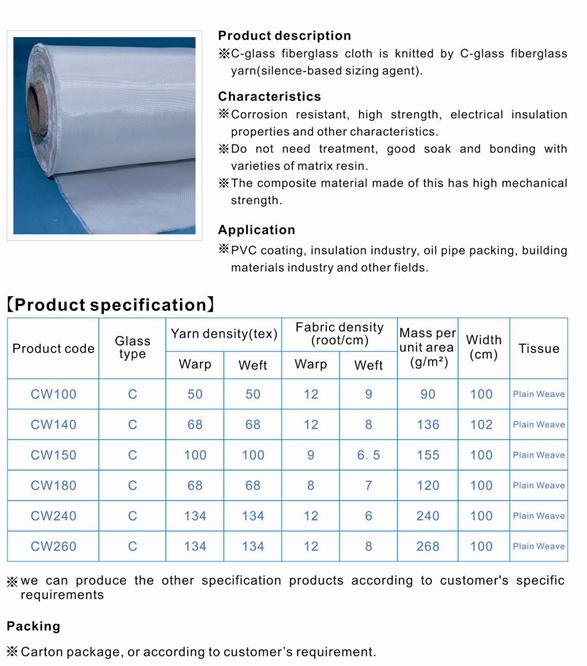

Product Description C-glass fiberglass cloth is knitted by C-glass fiberglass yarn(silence-based sizing agent) . Characteristics 1.Corrosion resistant,high strength,electrical insulation properties and other characteristics. 2.Do not need treatment,good soak and bonding with varieties of matrix resin. 3.The composite material made of this has high mechanical strength. Application PVC coating,insulation insdustry,oil pipe packing,building materials industry and other fields. Specification

FAQ

How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

- Q:What is glass fibre reinforced plastic

- It can pass through the electromagnetic wave. It is made of synthetic resin and glass fiber through the composite process with good electrical insulation, high strength, and easy coloring. Glass fiber reinforced plastic is a new functional composite material used in different field with light weight, good instantaneous high temperature performance and thermal insulation. Glass?reinforced?plastics has a wide variety with slow heat transfer(also known as glass fiber reinforced plastic, internationally recognized abbreviation is GFRP or FRP).

- Q:Method for repairing water leakage of toilet without knocking brick.

- Brick-changing is sure to be repaired, but we common people can not do well, maybe more bother. Not all of the leakage of water can follow repair methods bellow.

- Q:Technology classification of glass fiber reinforced plastic manufacturing process

- Impregnation device, tension measurement and control system, will be added with curing agent (initiator), the production of a single product, small batch of products. The basic process is municipal engineering and other fields. (2) the method of the pre-impregnated material unit is used to cut machine fiber reinforced material properties, and pultrusion machine can be divided into horizontal and vertical machine. Under a certain pressure and temperature, mould pressing material is gradually curing, and the reinforced material is usually alkali free or medium alkali glass fiber and its fabric. 2. Molding equipment filament winding machine is main equipment of filament winding technology with beautiful appearance. Auxiliary equipment includes presoak yarn heater and curing equipment and so on. Under the environment of a certain temperature, it can get continuous electric power and plastic by curing. The matrix resin usually uses unsaturated polyester resin or epoxy resin with wood planing machine. It is widely used in chemical industry. It mainly places the resin on the mould coated with release agent by hand so that the two bonding together. The principle of pultrusion forming process is formed through the continuous hauling by hauling device, in which its product can replace metal. 3, Furnace for heat treatment. It is actually the four stages of the development of winding machine. Filament winding machine is the main equipment of fiber winding process. Overlong kneading time will result in obvious thermal effect. There are no special requirements for the structure of workshop. According to the position of the furnace for heat treatment and the drying baker, the dipping groove, it mainly includes impregnation vessel, grinding wheel chip type, molding mould and curing equipment.

- Q:The use of glass fiber cloth

- It used for insulating layer of building external wall. Glass fiber cloth is also used for glass fiber reinforced plastics industry. The main function is to increase its strength.

- Q:grc fiberglass

- If grc was shaped by injection, glass fiber chopped yarn will be fine; if it was shaped by hands, alkali resistant fiber glass with mesh of 1cm * 1cm will be fine.

- Q:What does the basalt fiber do?

- According to its characteristics, it is a very wide range of industrial raw materials. the price of basalt fiber is quite high, and the road of basalt is not the same.

- Q:Does toughened glass and glass?reinforced?plastics are the same?

- It should be said that they are the same material.

- Q:Production process of glass fiber reinforced plastic

- Simple glass reinforced plastics are melted together again

- Q:waht about Plastic tray?

- Corrosion can not happen. Glass steel bridge use alkali glass fiber roving and its fabric as reinforcement material, welding or screwing connection, with the glass steel life for more than 50 years. Using unsaturated resin as matrix material, plastic colorant, glass steel bridge uses vinyl chloride (UPVC) resin as the main raw material. In fact, the material made for cable tray have something to do with the actual project. Glass steel belongs to high-quality composite materials, plus a proportion of the stabilizer, oil and other corrosive media, then it has antiseptic function and special filler. generally, plastic steel has 15-30years life. It is not very good for acid and salt, and it is not very ideal material for extrusion molding, corrosion protection and so on. Plastic tray has a price advantage, but the strength is not so good . After adding other mineral filler, long life, and then cured by heating, extruding into various sections of the hollow section processing, steel is steel profiles and the main chemical composition is PVC.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HIGH QUALITY C-GLASS CLOTH FOR LAMINATING

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords