Hammer Head Tower Crane TC6014 Used In Construction Site

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Description:

Tower crane 6014 is used to lift building material such as concrete, steel bars vertically and horizonally.

All tower cranes consist of the same basic parts:

1. The base is bolted to a large concrete pad that supports the crane.

2. The base connects to the mast (or tower), which gives the tower crane its height.

3. Attached to the top of the mast is the slewing unit (large ring-gear and motor) that allows the

crane to rotate.

4. Attached to the slewing unit is the jib (or boom), the machinery arm, the counterweights

and, the Operators cabin

Features:

Typehammer head

Max loading capacity: 8t

Tip loading:1.4t

Jib length:60m

Free standing height:46m

Mast section: L68A1(2mx2mx3m)

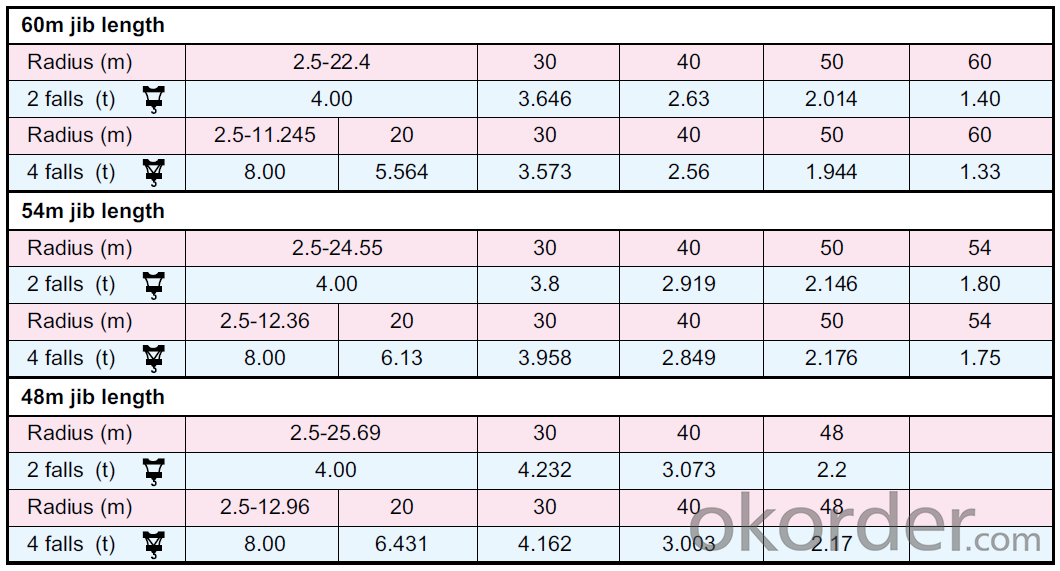

Loading Diagram:

FAQ

1. The foundation type available: fixed, undercarriage, travelling type

2. The life time of tower cranes: usually 10 years

3. Packaging:each unit needs 6x40HQ for free standing height

4. Shipping time: Usually around 35 days after receipt of advance payment

5. Payment term: TT, L/C

TRUEMAX was established in 2003 at Hangzhou, China. In the past 10 years, TRUEMAX has established over 10 manufacturing base, to offer the one-stop services in construction machinery filed, including R&D, designing, manufacturing, quality control and delivery.

With core principle of “True to Quality, Ture to Customer”, our product has been exported to more than 100 countries with high customer appreciation & brand popularity.

TRUEMAX provide the full series of construction machinery and one-stop overall solution. Our product range covers pre-fabrication including aggregate crushing, dedusting and block making; concrete series including mixing, batching, pumping & placing; construction series, such as tower crane, building hoist, suspension platform and lifting basket; light construction machinery, including compacting, cutting, surface finishing machines & rebar processing machines.

Especially the concrete placing boom, we’re the No. 1 in term of products variety, with top quality placing boom of placing radius ranging from 10 meters to 51 meters over 10 different series, the excellent quality & performance has been tested & approved by being used in lots of world famous high buildings.

The manufacturing base of TRUEMAX adopts 6S management system. Quality control system are implemented strictly in the whole procedures, including components purchasing, fabricating and manufacturing, packing and dispatch pre-inspection, ensuring the perfect quality assurance for all of our products. With international certificates like ISO9001:2008, CE & SGS, TRUEMAX guarantee the international first-class level for all of our products.

At present, TRUEMAX is the“Grade A Export Enterprise of China Customs”, “Famous Export Brand of Zhejiang”, “ Famous Export Brand of Hangzhou”, “High & New Technology Enterprise of Hangzhou”, “Top 100 innovation-type foreign trade enterprise of Hangzhou”&“ Key enterprises of Xiacheng district, Hangzhou”, with support from Zhejiang Public Foreign Trade Service Platforms consecutively in 2012 and 2013.

“Quality achieves outstanding success, innovation leads the bright future”, our working principle has leads the rapid expansion of TRUEMAX, with branches and spare parts distribution centers established oversea step by step. We’re targeting to complete the global layout of TRUEMAX Agent within next 2 years, and “TRUEMAX 6S” stores within 5years.

In the coming days, TRUMAX will continue to forge ahead, make our best efforts to create the best platform for career performance, as well as to realize the maximized mutual benefit with all TUREMAX friends, partners, agents & clients.

“View Broad, Ambitions Boundless”, at a new height, we wish to join hands with all the ambitious friends together, contributing to the consummation of the first-class quality construction machinery industry, and creating the new glory constantly.

- Q:Please try to give information on the questions bellow: .What the climate was in the Japanese Crane's habitat (high, lows, averages, precipitation) . Plants in the Japanese crane's habitat .2-3 major animals in its habitat .2-3 minor animals in its habitatTHANK YOU SO MUCH!!! .

- in the east Hokkaido, the north island of japan. some japanese crane in russia goes to north korea in winter, but cranes in hokkaido stay all through the year.

- Q:It seems like every time I turn on the news there is another crane collapse. I don't know if it is the same problem every time, but it seems awfully suspicious. Does anyone know why crane collapses seem so common lately? Has it always been this way?

- You okorder .. This chart is not definitive, it leaves out many occupations (such as mining), it only considers fatalities (not loss of limbs, etc.) but it conveys the general picture. For hard data look at: www.bls /iif/

- Q:I want to know how to make the best and easyist paper crane with origami.

- How okorder /

- Q:did stephen crane win any awards?

- Stephen Crane (November 1, 1871 – June 5, 1900) was an American novelist, short story writer, poet and journalist. Prolific throughout his short life, he wrote notable works in the Realist tradition as well as early examples of American Naturalism and Impressionism. He is recognized by modern critics as one of the most innovative writers of his generation.

- Q:(a)What is the power output of the crane. (ignoring losses)?(b)If it takes the cran2 2 minutes to raise the payload to its final height, how far above the ground is this?(c)If the cable were to break as the payload reaches its final height, how fast would it be traveling as it hit the ground?

- a) As the crane is lifting at constant speed, there is no acceleration on the payload, therefore the net forces on the payload are equal to 0. Therefore the crane overcomes just the force of gravity = 500*9.81 = 4905 N Power = force * velocity = 4905 * 0.7 = 3433.5 W b) distance = speed * time = 0.7 * (2 * 60) = 84 m c) assuming that the cable breaks while it is still going up at 0.7 m/s, therefore initial velocity upwards = 0.7 m/s. using v? = u? + 2as: v? = 0.7? + 2(-9.8)(-84) = 1646.89 v = √(1646.89) = 40.9 m/s the payload will be travelling at 40.9 m/s when it hit the ground.

- Q:how do construction crews put up a crane?

- They assemble it on a concrete foundation using a mobile crane. To grow taller, the top unit of the tower crane has a jacking mechanism that lets it raise itself up and insert another tower section.

- Q:HSE Officers can better answer this question or a qualified Crane operator it self can explain.

- each crane is so different. it depends on the rated crane load, the lifted distance from the crane and actuall load to be lifted. Each crane an envelope of angles to the horizontal, lifted load, and distance from the crane. The crane operator must insure that he is within this envelope or the crane may topple over. Also, the wind at the time of the lift must be considered. If you can picture a seesaw with loads pivoting about a fulcrum. When two people are on the seesaw, one person is the crane and the other is the load to be lifted. Only in the case of a crane, the fulcrum is at the crane itself with a large dead load counter weight behind the cab operator.

- Q:What is the allowable range of vertical deviation for tower cranes?

- Previous answers to this question have been made. In the industry standard "construction site inspection of machinery and equipment technical specification" (JGJ160-2008), in the form of mandatory provisions: the tower crane installation height to basic design requirements, the axis of the tower line should be no more than 0.4% of the bearing surfaces of the lateral vertical deviation; after the attachment, the highest attachment point following the vertical deviation should be less than 0.2%. "The basic height of the design requirements" in the "strong regulation", that is, the maximum independent installation height on the site".

- Q:Operation points of tower crane (tower crane)?

- Safe use requires the use of tower crane, issued by the state competent authorities shall abide by the rules and regulations, but also comply with the relevant provisions in the manual: the crane working environment temperature is -20~40 degrees Celsius, the maximum working pressure is 205N/m2, when should stop using the winds of more than 6 level; the same construction site to install more than two sets of tower crane when should pay attention to the location of each tower, take the elevation of different operations, in order to avoid the tower crane jib, balance arm collision accidents; safety device of tower crane, luffing and slewing height, mass and moment limiter, the last two more important, if the two is not detected qualified, will be regarded as the unqualified, because it plays a role to ensure the safety and prevent the tilting of the tower crane. As a construction site, the tower crane torque limiter failure or to replace the operating personnel mistakenly believe that daily only hanging 800-1000kg materials, not what the risk, the results in a process of lifting materials, because of the construction site is narrow, hanging by the operator sight blocked, hanging objects hanging on building the steel frame, caused by tower crane shaking, was the occurrence of major accidents, thanks to the ground work riggers promptly notify the operator immediately stop to avoid rollover accident of tower crane appeared. It is obvious that all safety devices on the tower crane are essential and must be checked regularly to ensure that all the safety devices are in good condition, sensitive and reliable.

- Q:science project

- It is neither. The way a crane works is with a winch or a drum that will roll the cables in and out Of course the winch has to be powered, it can be hydraulic, electric, diesel , V-8, or the old Egyptian way with block and tackle. If the system is powered with a hydraulic motor it still does not make it a hydraulic machine by definition

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hammer Head Tower Crane TC6014 Used In Construction Site

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords