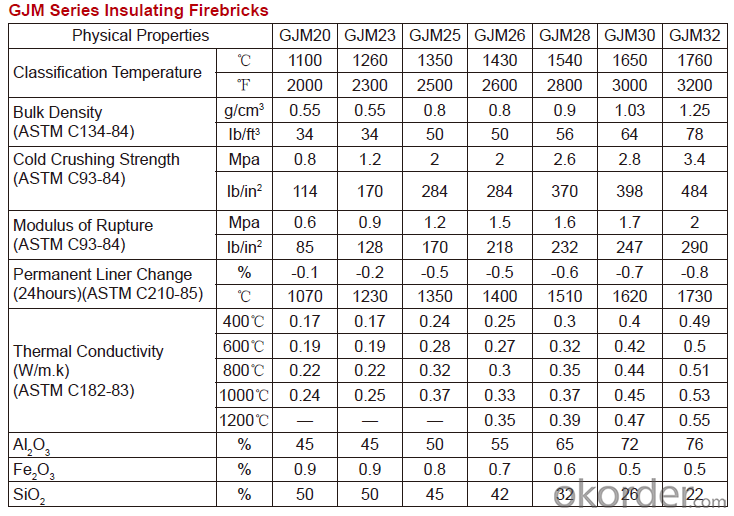

GJM 28 Light Dense Mullite Insulation Brick Produc

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

Refractory brick is a refractory material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment and good service

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

3 large flexible crushing and sieving lines for grit production lines

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q:What is the typical weight of an insulating fire brick?

- The weight of an insulating fire brick can differ based on its specific type and manufacturer. On average, it falls within the range of 2.5 to 3.5 pounds (1.1 to 1.6 kilograms). It's worth noting that this weight estimation applies to a standard-sized brick measuring 9 x 4.5 x 2.5 inches (22.9 x 11.4 x 6.4 centimeters). Slight variations in weight may occur due to varying densities and compositions of these bricks. Therefore, it is advisable to consult the manufacturer's specifications for precise information.

- Q:Are there any safety precautions to consider when using insulating fire bricks?

- Yes, there are safety precautions to consider when using insulating fire bricks. Firstly, it is important to wear appropriate personal protective equipment, such as gloves and safety goggles, to protect against potential injuries. Additionally, due to the high temperatures involved, it is crucial to handle the bricks with care to avoid burns or related accidents. Adequate ventilation should be ensured to prevent the buildup of harmful gases and fumes. Lastly, it is essential to follow the manufacturer's instructions and guidelines for proper installation and usage to minimize any potential risks.

- Q:Are insulating fire bricks suitable for outdoor use?

- Insulating fire bricks are not typically suitable for outdoor use due to their lower density and higher porosity compared to other types of bricks. These bricks are designed for use in high-temperature applications such as furnaces and kilns, where they provide excellent insulation properties. However, when exposed to the elements, insulating fire bricks may absorb moisture and be prone to cracking or deteriorating over time. For outdoor applications, it is generally recommended to use dense fire bricks or other types of bricks that are specifically designed for outdoor use, as they have greater durability and resistance to weather conditions.

- Q:Can insulating fire bricks be used in drying ovens?

- Certainly, drying ovens can utilize insulating fire bricks. Specifically engineered with low thermal conductivity, these bricks prove to be a superb option for heat insulation purposes, notably in drying ovens. They possess the ability to endure elevated temperatures and efficiently insulate the oven, thereby aiding in maintaining the desired temperature and minimizing heat dissipation to the surroundings. Moreover, their lightweight nature and ease of installation render insulating fire bricks a highly practical selection for incorporation into drying ovens.

- Q:Do insulating fire bricks expand and contract with temperature changes?

- Yes, insulating fire bricks do expand and contract with temperature changes.

- Q:How shall the sintered porous self insulation bricks be laid at the bottom of the beam?

- All reserved holes larger than 200 * 200 shall be reserved

- Q:Can insulating fire bricks be used in ceramic fiber boards?

- Insulating fire bricks have the potential to be utilized in ceramic fiber boards. They are commonly employed as a lining material for high-temperature purposes due to their ability to endure extremely high temperatures and offer exceptional thermal insulation. Conversely, ceramic fiber boards are lightweight and possess commendable thermal shock resistance, rendering them suitable for employment in diverse industrial and residential settings. When utilized in conjunction, insulating fire bricks can be positioned behind or around the ceramic fiber boards to augment their insulating properties and elevate overall thermal efficiency. The bricks have the capability to provide additional structural support and assist in retaining heat within the system, thereby enhancing energy efficiency and minimizing heat loss. Nevertheless, it is crucial to acknowledge that the compatibility of insulating fire bricks and ceramic fiber boards might fluctuate based on the specific application and requirements. It is advisable to seek guidance from manufacturers or industry professionals to ensure appropriate selection and installation of these materials according to your individual needs.

- Q:Can insulating fire bricks be used in ladles and tundishes?

- Yes, insulating fire bricks can be used in ladles and tundishes. Insulating fire bricks are designed to withstand high temperatures, making them suitable for use in these refractory applications. They provide excellent thermal insulation, reducing heat loss and improving energy efficiency in ladles and tundishes.

- Q:Can insulating fire bricks be used in combination with other insulation materials?

- Yes, insulating fire bricks can be used in combination with other insulation materials. Insulating fire bricks are known for their excellent thermal insulation properties and can be used to effectively reduce heat transfer in various applications such as kilns, furnaces, and fireplaces. However, in some cases, additional insulation may be required to achieve optimal thermal efficiency. Combining insulating fire bricks with other insulation materials can further enhance the overall insulation performance. For example, ceramic fiber blankets or boards can be used alongside insulating fire bricks to provide additional insulation and to fill any gaps or joints between the bricks. This combination can help minimize heat loss and improve energy efficiency. Furthermore, using multiple insulation materials can also provide other benefits such as increased fire resistance, improved sound insulation, and enhanced structural integrity. By utilizing different insulation materials in combination, it is possible to create a more effective insulation system that meets specific requirements for different applications. It is important to consider the compatibility and compatibility of the different insulation materials when combining them. Each material may have different thermal properties, density, and installation requirements, so it is crucial to follow the manufacturer's recommendations and guidelines for proper installation. In summary, insulating fire bricks can be used in combination with other insulation materials to enhance thermal insulation and improve overall performance in various applications. However, it is essential to ensure compatibility and follow proper installation guidelines for optimal results.

- Q:Do insulating fire bricks have a low thermal expansion rate?

- Insulating fire bricks are known for their low thermal expansion rate. They are specifically designed to endure high temperatures and thermal shocks, with one of their key features being their ability to retain their shape and dimensions even in extreme heat conditions. These bricks are produced from materials that possess a low coefficient of thermal expansion, which means they undergo minimal expansion and contraction when exposed to temperature changes. This characteristic guarantees the stability of the bricks, preventing them from cracking or breaking due to thermal stress. Moreover, the low thermal expansion rate of insulating fire bricks contributes to improved insulation performance. By minimizing the formation of gaps between the bricks during expansion and contraction, heat loss is reduced and energy efficiency is enhanced.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GJM 28 Light Dense Mullite Insulation Brick Produc

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords