Geomembrane Thickness 2.5MM for Architectural Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geomembrane for Architectural Engineering

Description Of Geomembrane for Architectural Engineering

Geomembrane, as water-proof plate, is made from polymer materials like polyethylene, through blow molding.

Main Features of Geomembrane for Architectural Engineering

By its raw materials - molecular structure, Polyethylene (PE) geomembrane is divided into low-density polyethylene (LDPE) geomembrane, linear low density polyethylene (LLDPE) geomembrane

Applications of Geomembrane for Architectural Engineering

1. HDPE geomembrane is applicable to environmental protection and sanitation: such as landfill, sewage treatment plant, power plant adjustive pool, industrial, hospital solid waste;

2. HDPE geomembrane is applicable to hydraulic engineering: such as seepage control, plugging, reinforcement for rivers, lakes and reservoirs and dams, drainage seepage control, vertical core wall, slope protection, etc.

3. LDPE geomembrane's applications in municipal engineering: subway, underground works of the building, planting roof, roof garden, sewage pipe seepage control;

4. Polyethylene impermeable membrane is applicable to the garden: artificial lake, river, reservoir, golf course pond bottom, slope, green lawn waterproofing and damp-proofing;

5. High density polyethylene geomembrane is applicable to petrochemical industry: chemical plant, oil refinery, storage tank seepage control, chemical reaction cell, lining and secondary lining for sedimentation tank, etc.

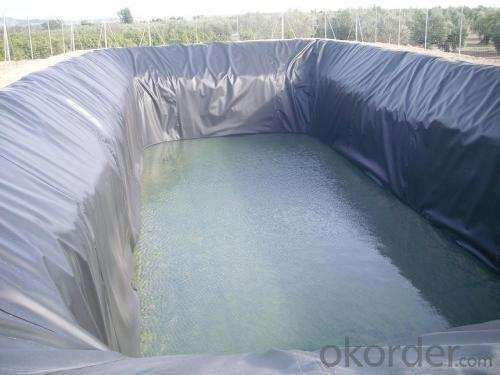

IMages of Geomembrane for Architectural Engineering

FAQ:

1. What are we supplying?

We are specialized in producing , geocell, geogrid, geomembrane

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q:How is the geothermy film?

- The electrothermal?film efficiency will decrease with the usage rate year by year, so it is recommended that you should be better to use oil heater according to the size of your room. The service life of oil heater is longer than that of electrothermal?film and it is more practical than the electrothermal film. You can choose Xianfeng oil heater, which is cost-effective and professional.

- Q:How do geomembranes perform in extreme weather conditions?

- Geomembranes are designed to be highly durable and resilient, allowing them to perform well in extreme weather conditions. They are able to withstand harsh temperatures, UV radiation, and even freeze-thaw cycles without significant degradation. Additionally, geomembranes have excellent resistance to chemicals and can maintain their integrity in heavy rainfall, strong winds, and intense sunlight. Overall, their exceptional performance in extreme weather conditions makes them a reliable choice for various applications, such as landfill liners, pond liners, and mining containment systems.

- Q:Can geomembranes be used in hydraulic applications?

- Yes, geomembranes can be used in hydraulic applications. Geomembranes are impermeable liners made of synthetic materials like PVC, HDPE, or LDPE, which can effectively prevent the seepage of water or other fluids. They are commonly used in hydraulic applications such as reservoir lining, pond lining, canal lining, and as barriers in landfills or wastewater treatment systems. Geomembranes provide excellent resistance to hydraulic pressure, chemical corrosion, and UV exposure, making them suitable for various hydraulic engineering projects.

- Q:Can geomembranes be used in stormwater management?

- Yes, geomembranes can be used in stormwater management. They are often utilized as liners or covers for stormwater ponds, retention basins, or other containment systems to prevent the infiltration of water into the ground and to control erosion. Geomembranes help to contain and control stormwater runoff, reducing the risk of pollution and protecting the environment.

- Q:What are the applications of geomembrane in roadbed?

- Waterproof

- Q:why is the lateral welding edge of composite geo-membrane so dim?

- Try to choose new materials to produce geomembrane

- Q:How do geomembranes help in groundwater recharge projects?

- Geomembranes help in groundwater recharge projects by acting as a barrier to prevent the loss of water through seepage and infiltration. They are used to line the recharge basins or ponds, ensuring that the water is effectively contained and slowly percolates into the ground, replenishing the groundwater reserves. This not only helps to conserve water but also prevents contamination and ensures the efficient recharge of aquifers.

- Q:Can geomembranes be used in coal ash containment?

- Yes, geomembranes can be used in coal ash containment. Geomembranes are commonly employed in such applications to provide a reliable barrier and prevent the migration of contaminants, including coal ash, into the surrounding environment. They are designed to withstand the harsh conditions and chemical exposure associated with coal ash, making them an effective solution for containment.

- Q:How do geomembranes contribute to erosion control in pipeline and utility corridor construction?

- Geomembranes contribute to erosion control in pipeline and utility corridor construction by providing a reliable barrier against soil erosion and water infiltration. These impermeable membranes are installed as liners or covers in areas prone to erosion, such as slopes and embankments, to prevent the loss of soil particles and the formation of gullies. By effectively containing soil and water, geomembranes help maintain the stability and integrity of the construction site, reducing the risk of damage to pipelines and utility corridors from erosion-related issues such as sedimentation or landslides.

- Q:How to deal with the bubble in the mobile phone film?

- The problem is the film quality. You should first clean the screen, otherwise it will blister. You'd better buy the film with good quality, otherwise it can not use a long time.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Geomembrane Thickness 2.5MM for Architectural Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords