GATE VALVE SOCKET ENDS NON-RISING STEM RESILIENT SEATED DUCTILE IRON DN50 - DN300

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Standard or Nonstandard: | Standard | Structure: | Gate | Pressure: | Normal Pressure |

Power: | Hydraulic | Material: | Casting | Temperature of Media: | Normal Temperature |

Media: | Water | Port Size: | DN50~DN300 | Place of Origin: | China (Mainland) |

Model Number: | DIN3352/SABS664 | Brand Name: | CMAX | Surface: | Powder coating/Acid pickling/Paint |

Test: | 100% water pressure |

Packaging & Delivery

Packaging Details: | Standard export package or as per your requirement |

Delivery Detail: | 20-25 Days, depends on the demand quantity |

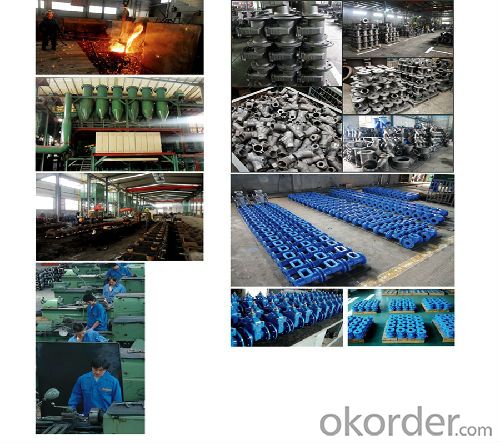

Details of Socket End Non-Rising Stem Gate Valve:

1) Design and Manufacture Standards:

a. DIN3352

b. BS5163

c. ANSI B16.34

d. API60

e. API6D and Russian standard

2) Material:

a. Cast Iron (GG20, GG25)

b. Ductile Iron (GGG50)

c. Carbon Steel, WCB

d. Stainless steel

3) Sealing:

a. Rubber

b. Metal

4) Operation:

a. Hand-wheel

b. Driving head

c. Electric actuator

5) Media:

Water, Oil etc.

6) Working pressure:

a. 1.0Mpa

b. 1.6Mpa

c. Class150LB-2500 LB

7) Working dimensions: DN50-DN800

8) Temperature: Normal Temperature

9) Coating:

a. Fusion Bonded Epoxy Powder Coating

b. Akzo Nobel Powder Coatings

- Q:What's the meaning of flexible z45x-10q door valve?

- Crown valve pressModel Z45X-10QZ refers to gate valve4 finger flange connection5 refers to the dark bar driveX refers to rubber seals10 refers to 10 kg pressureQ refers to the body material, ductile ironFull bore flange soft sealed gate valve

- Q:Valve flange drawing n- up to what

- A bolt hole used to indicate a flangeThe value of N indicates the number of bolt holesUp to the numerical representation of bolt hole size

- Q:What's the meaning of the gate valve model z41x 16Q?

- Gate valve (Z) flange connection (4) wedge type single gate (1) rubber soft seal (X) -16 pressure) (Q)

- Q:What is the gate valve for the DN65 hydrant?

- Fire hydrant with 65 butterfly valve, ah, how do you use the gate valve?

- Q:What is an inverted seal gate valve?

- When the inverted sealing gate valve is fully opened, the sealing of the sealing is brought together, and the sealing effect is reduced, and the erosion of the filling to the fluid is reduced, and the service life of the filler is prolonged, and the possibility of leakage is reduced. Generally on the gate valve, stop valve has inverted sealing requirements.

- Q:What is the difference between a flanged gate valve and a wire gate valve?

- Flanged gate valves are flanged and must be welded to the flanges of the pipe, bolted together

- Q:Notes on flat gate valves

- Use, maintenance, maintenance and precautions1. valve before leaving the factory have made strength and sealing test, the use of all connections should maintain the initial state.2. this series of valve operating handwheel is marked with open and close rotary direction, and the upper part of rod is equipped with open and close height gauge for regulating indication.3. when the valve and pipeline welding, the valve should be opened, appropriate to protect the neck with moisture, minimize heat conduction, to prevent damage to the sealing packing parts.4. when the valve is closed, the lever shall not be used. When the gate is closed to the top, the handwheel shall be turned 1/2 so that the gate is in a floating state.5. in the use of the valve should be regularly to the valve cap injection grease joint into the quantitative grease.6., the valve in use, such as vulnerable parts and leakage, should be replaced in time.7., the valve in the overhaul process, the cavity should be cleaned, the assembly should be added to the transmission parts of grease.8. valve storage during the shutdown, the gate should be in the closed position, long-term storage should be placed in ventilated dry place, regular inspection and maintenance.

- Q:What is the difference between gate valve Z41T and Z45T?

- Valve Z41T and Z45T difference is that "41" is dark rod, that is, the screw is not out of the turbine,"45" is the bright rod, that is, the screw out of the turbine.Common points are copper sealed gate valves.

- Q:What do you mean by forged steel gate valves 800LB DN20 SW?

- Is the forged steel gate 800LB is DN20 on SW welding pressure

- Q:What does "Z45W-10T" mean?What does each letter stand for?

- T is the material code for the valve body, which stands for copper and copper alloysZ45W-10T, which means manual, flange connections, dark wedge rigid single gate plate, the valve seat sealing surface material directly processed by the valve body, nominal pressure PN10, valve body material for Brass Gate Valve

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GATE VALVE SOCKET ENDS NON-RISING STEM RESILIENT SEATED DUCTILE IRON DN50 - DN300

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords