Fiber Glass Stitched Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 12000 kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

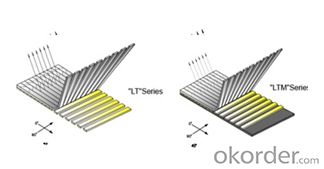

(0°/90°) series mat:

Two layers of roving(550g/㎡-1250g/㎡) are aligned at 0°/90° with or without a layer of chopped strands(0g/㎡-500g/㎡)。The product has a maximum width of 100 inches.This product can be used for manufacturing boats,cases and shell of car.

2.Product Structure

3.Product Specifications

Product No. | Overall Density | .0° Roving Density | .90° Roving Density | Chop Density | Polyester Yarn Density |

(g/m2) | (g/m2) | (g/m2) | (g/m2) | (g/m2) | |

E-LTMC1603 | 671.74 | 303.8 | 247.96 | 101.62 | 18.36 |

E-LTMC1608 | 844.76 | 303.8 | 247.96 | 274.64 | 18.36 |

E-LTMC1808 | 903.8 | 303.8 | 307 | 274.64 | 18.36 |

E-LTMC1810 | 934.31 | 303.8 | 307 | 305.15 | 18.36 |

E-LTMC1815 | 1086.89 | 303.8 | 307 | 457.73 | 18.36 |

E-LTMC2408 | 1101.04 | 405.66 | 401.46 | 274.64 | 19.28 |

E-LTMC2415 | 1284.13 | 405.66 | 401.46 | 457.73 | 19.28 |

E-LTMC3205 | 1272.69 | 607.6 | 491.86 | 152.58 | 20.65 |

E-LTMC3205-HS | 1388.43 | 607.6 | 607.6 | 152.58 | 20.65 |

E-LTMC3208 | 1394.75 | 607.6 | 491.86 | 274.64 | 20.65 |

E-LTMC3610 | 1541 | 607.6 | 607.6 | 305.15 | 20.65 |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the roll has a diameter of 275mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q:How is fiberglass fabric used in the production of thermal curtains?

- Fiberglass fabric is commonly used in the production of thermal curtains due to its unique properties and benefits. Firstly, fiberglass fabric is known for its excellent insulating properties, which makes it a perfect material for thermal curtains. The fabric acts as a barrier against heat transfer, helping to maintain a stable temperature inside a room. In the production of thermal curtains, fiberglass fabric is often used as a lining or an interlining. It is sandwiched between the decorative outer fabric and the inner lining of the curtain. This layer of fiberglass fabric adds an extra layer of insulation, preventing heat loss in the winter and heat gain in the summer. Additionally, fiberglass fabric is lightweight and flexible, making it easy to work with during the manufacturing process. It can be easily cut, sewn, and tailored to fit various curtain sizes and designs. Moreover, fiberglass fabric is durable and long-lasting, ensuring that thermal curtains made from this material will withstand frequent use and maintain their insulating properties over time. Furthermore, fiberglass fabric is fire-resistant, adding an extra layer of safety to thermal curtains. This property is crucial in preventing the spread of fire and protecting occupants in case of an emergency. Overall, fiberglass fabric is an essential component in the production of thermal curtains. Its insulating, lightweight, flexible, durable, and fire-resistant properties make it an ideal choice for creating curtains that effectively regulate temperature, conserve energy, and enhance comfort in homes and commercial spaces.

- Q:How is fiberglass fabric used in the production of aircraft interiors?

- The production of aircraft interiors heavily relies on fiberglass fabric, as it possesses numerous benefits and properties that make it an ideal material for this purpose. Panels and partitions are among the primary applications of fiberglass fabric in aircraft interiors. Fiberglass fabric is renowned for its exceptional strength-to-weight ratio, making it a perfect choice for creating panels that are both lightweight and durable. These panels are used to separate the aircraft cabin into different sections, such as the cockpit, passenger area, and lavatories. The lightweight nature of fiberglass fabric helps reduce the overall weight of the aircraft, leading to improved fuel efficiency and enhanced performance. Another significant advantage of fiberglass fabric is its fire resistance. Aircraft interiors must adhere to strict fire safety regulations, and fiberglass fabric is inherently fire-resistant, making it a preferred material for constructing wall and ceiling panels. Even in the event of a fire, fiberglass fabric will not contribute to the spread of flames, giving passengers valuable time to evacuate safely. Fiberglass fabric is also utilized in the production of aircraft seats and upholstery. Its high tensile strength makes it suitable for seat covers, ensuring durability and resistance to wear and tear. Moreover, fiberglass fabric can be treated to be water-resistant, making it easier to clean and maintain. This is particularly important in the aviation industry, where hygiene and cleanliness are of utmost importance. Furthermore, fiberglass fabric is often employed in the creation of aircraft insulation and soundproofing materials. Its excellent thermal and acoustic insulation properties help maintain a comfortable cabin temperature and reduce noise levels, ultimately enhancing the overall passenger experience. To summarize, fiberglass fabric is an integral component of aircraft interior production due to its lightweight, fire-resistant, and durable characteristics. Its versatility extends to the construction of panels, seats, upholstery, insulation, and soundproofing, all of which contribute to the safety, efficiency, and comfort of modern aircraft interiors.

- Q:How do fiberglass fabrics perform in terms of UV resistance?

- Fiberglass fabrics possess impressive properties of UV resistance. The structure of fiberglass, composed of delicate glass fibers, enables it to endure extended exposure to ultraviolet (UV) radiation without significant deterioration. Unlike numerous other fabrics, fiberglass does not easily corrode or become brittle when subjected to sunlight. The inorganic nature of the glass fibers in fiberglass fabrics confers inherent resistance to UV rays. Consequently, they lack any organic compounds that can be disintegrated or degraded by UV radiation. Consequently, fiberglass fabrics can maintain their strength and integrity even after prolonged exposure to sunlight. Furthermore, fiberglass fabrics can be further fortified by the addition of special coatings or treatments, enhancing their UV resistance. These coatings offer supplementary protection against UV rays, thereby augmenting the fabric's durability and ability to withstand outdoor conditions. In summary, fiberglass fabrics are renowned for their exceptional UV resistance. They are widely utilized in applications that involve exposure to sunlight, such as outdoor furniture, marine applications, and automotive components. Their capacity to withstand UV radiation renders them a robust and dependable choice for various industries and environments.

- Q:Can fiberglass fabrics be used for insulation in HVAC systems?

- Indeed, insulation in HVAC systems can utilize fiberglass fabrics. The preference for fiberglass as an insulation material in HVAC systems stems from its exceptional thermal characteristics. Its low thermal conductivity enables it to effectively impede heat transfer. Fiberglass fabrics are typically employed to encase air ducts, pipes, and other components in HVAC systems to prevent heat loss or gain. Aside from its thermal efficiency, fiberglass fabrics possess other advantageous properties that render them suitable for insulation purposes. They are lightweight, flexible, and simple to install, making them a convenient option for HVAC insulation. Additionally, fiberglass fabrics exhibit resistance to moisture, mold, and mildew, thus contributing to the maintenance of satisfactory indoor air quality. Moreover, fiberglass fabrics boast outstanding fire-resistant qualities. They are non-combustible and do not emit toxic gases when exposed to high temperatures. Consequently, fiberglass fabrics constitute a safe choice for insulation in HVAC systems. All in all, the utilization of fiberglass fabrics for insulation in HVAC systems proves to be highly effective due to their thermal efficiency, ease of installation, resistance to moisture, and fire safety.

- Q:Can fiberglass fabric be used as a heat shield?

- Yes, fiberglass fabric can be used as a heat shield. Fiberglass is a highly heat-resistant material commonly used in applications where thermal insulation is required. It has excellent fire resistance properties and can withstand high temperatures without melting or deforming. Fiberglass fabric is often used as a heat shield in various industries such as aerospace, automotive, and construction. It is lightweight, flexible, and can be easily molded or shaped to fit different surfaces. Additionally, fiberglass fabric is known for its low thermal conductivity, meaning it is an effective barrier for heat transfer. Overall, fiberglass fabric is a reliable choice as a heat shield due to its high heat resistance, versatility, and durability.

- Q:How does fiberglass fabric perform in moisture absorption?

- Fiberglass fabric is known for its low moisture absorption capabilities. It has a hydrophobic nature which means it does not readily absorb water. This property allows it to maintain its strength and structural integrity even when exposed to moisture or high humidity conditions. Additionally, fiberglass fabric is resistant to mold, mildew, and rotting, further enhancing its performance in moisture absorption.

- Q:Glass fiber cloth, heat conduction double sided adhesive tape and no material heat conduction double sided adhesive tape difference? Which is better?

- Fiberglass cloth thermal double-sided tape (www.glpoly ): it is made of glass fiber cloth, PET, PVC film, non-woven material, double-sided evenly coated elastomer pressure-sensitive adhesive or resin adhesive, acrylic pressure-sensitive adhesive, adhesive made in the substrate roll or sheet belt, is composed of a substrate, adhesive, isolation of paper (film) parts.

- Q:Can fiberglass fabric be used for making roller blinds?

- Yes, fiberglass fabric can be used for making roller blinds. It is a popular choice due to its durability, light weight, and resistance to heat and moisture. Additionally, fiberglass fabric offers good light filtering properties, making it suitable for roller blinds.

- Q:Can fiberglass fabric be used in low-temperature applications?

- Yes, fiberglass fabric can be used in low-temperature applications. It is known for its excellent thermal insulation properties, making it suitable for use in environments with low temperatures. Additionally, fiberglass fabric retains its strength and flexibility even in extreme cold, making it a reliable choice for various low-temperature applications such as insulation, cryogenic storage, and cold weather clothing.

- Q:Is fiberglass fabric resistant to electrical conductivity?

- Indeed, fiberglass fabric exhibits resistance to electrical conductivity. Comprised of interwoven glass fibers, fiberglass fabric consists of materials that are incapable of conducting electricity. Consequently, electrical current is unable to pass through fiberglass fabric. Due to its exceptional insulating properties and ability to shield against electrical shocks, it is frequently employed in electrical insulation applications. The non-conductive property of fiberglass fabric renders it a viable option for a wide range of electrical and electronic applications that necessitate prevention of electrical conductivity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiber Glass Stitched Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 12000 kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords