Fiber Cement board for villas,high building-003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The fiber cement board includes two series: solid fiber cement board(S series) and hollow fiber cement board (K series)

Fiber cement board is one new type wall board which is both functional and decorative, with idea of high- tech and innovation, the products combine the traditional and modern science and technology, which provide a brand new green wall decoration material to the exterior wall field.

K series

3000 * 300* 15mm

3000* 450* 18mm

3000*600* 26mm

K series—Streak board

3000*300*18mm

3000*300*22mm

3000*600*26mm

The colors are based on customer’s choice.

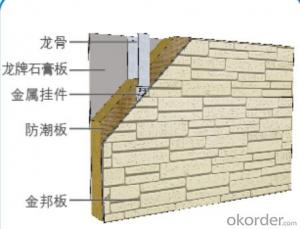

Fiber cement board: exterior wall decoration system

This system is widely used in public building and high end residential and other kinds of civil construction of exterior wall decoration. In existing buildings exterior wall decoration, the fiber cement board can be directly mounted to the exterior wall by keel, and not need to remove the original façade decoration materials. This system could give the construction quick speed, low transformation cost and good decorative effect.

Fiber cement board: exterior wall heat preservation system.

This system can meet different design requirements for energy- saving. The system has excellent heat preservation and heat insulation performance, meanwhile, the mass production and quality control of the products overcomes the crack problem occurred in other external insulation system. The system are mainly used in energy saving renovation to existing building or the external wall thermal insulation of new construction.

Fiber cement board composite wall system has good heat preservation, heat insulation and sound insulation performance, which make the system become an high and energy saving wall retaining system. The system could be applicable to the façade of steel or wood frame villa, and non bearing exterior wall for structural frame work or other frame structure.

- Q:Bathroom with cement board hanging the top, now open the hole to install the lights, so hard to open Oh ,,, which big god to help me out of ideas? Thank you!

- With the impact drill easy to break the tiles, you can go to the decorative supplies store to buy a drill bit of glass drill, very good, the effect is very good.

- Q:hi, this is my question:To prevent a cement mixer sinking into soft ground, the mixer is placed on a large flat board. Why does this prevent the mixer sinking?the answer will be one of these, which one is it?A The large area decreases the pressure on the ground.B The large area increases the pressure on the ground.C The large area decreases the weight on the ground. D The large area increases the weight on the ground.

- the flat board distributes the weight over a larger area, so the pressure per square inch is reduced.

- Q:Can cement pressure plates be used for external walls? Oblique wall, can play a waterproof role? Durable?

- Cement pressure plate is a fire board, mainly with cement and fiber by high temperature and high pressure

- Q:I am planning on doing cement around bath and shower in my home. i already have cement backer board up and wire mesh screening. what do i use to make it not crack and smooth and what material do i use

- Not very practical. How do you clean the concrete surface? That's why tile is so popular, it's washable. Say nothing for smooth stone, Corian, even fiberglass bath panels. It will be mildewed and soap scum stained within a month of use. No thanks, not in my house.

- Q:Can tiles be attached to gypsum board?

- In the cut off the plate, can play a moisture-resistant role is the fiber cement board (Eide board). It is a fiber reinforced silicate plate, the main raw material is cement, plant fiber and minerals, by the high temperature autoclaved pressure, mainly used as building materials.

- Q:How to maintain cement board

- According to the difference between the season and the temperature, the cement is fully hardened, that is, the maintenance of the general principle is 28 days, but the actual project which has a greater access, the specific maintenance period should be based on structural type, cross-sectional size, concrete label, cement varieties Temperature, humidity, evaporation, curing technology and other conditions to determine the specific, but the general summer curing of ordinary concrete 15 days is sufficient to achieve the winter sometimes, such as concrete pavement sometimes poor conditions or even two months are difficult to achieve sufficient strength, but no matter What concrete what curing conditions, the first 7 days must ensure that the cover insulation moisturizing conservation, for the harsh conditions of conservation can be used to warm water or even pressure water conservation.

- Q:Can I just paint a stone on a cemented fiberboard?

- Can be painted, and my 6 big house is used to make this kind of plate for the compartment, for the rental.

- Q:I'm ready to tile my kitchen soon. My husband and I have torn up the carpet and 2 layers of linoleum, leaving only some leftover glue from the linoleum and the wood sub floor. Do we really need to lay cement board over the wood sub floor or can we just go ahead and tile right on the wood? (FYI: it will be either ceramic or porcelain tile)

- You probably have 3/4 subfloor of plywood. You need a total of 1-1/8 of plywood or plywood and cement board base. Go with the tile but you must have a minimum of 1-1/8 subfloor. Good luck and happy flooring.

- Q:I'm laying slate tile over linoleum that was installed about 6 months ago....the linoleum is in very good condition, very smooth with no rips or lifting. I've done some research and figured I could put down cement board and then lay the tile on that. The floor under the linoleum is cement. Is there a special drill/special screw necessary to attach the cement board to the cement foundation?

- I really like Woodtick's answer, and i want to encourage you to not bother with trying to install concrete board on top of a concrete floor. Not only is it very redundant, and expensive, and timely, but you also run the risk of seeing your concrete board crack under the tile, which would cause uneven surfaces and even tile breaks after installation. Concrete board is not very flexible, and is designed to go over soft, water damage prone materials such as wooden studs and joists. It would be a more structurally sound idea, and easier, and cheaper to buy a heat gun to remove the linoleum and adhesive with a scraper and lay tile on that.

- Q:When laying down cement backer board for a slate tile installation, I laid the board a bit too far from the wall, so I pushed it until it was flush with the wall. I think by doing this I must have shifted some of the thinset underneath, because I noticed that the board has a slight dip in it, of maybe 1/16-1/8. Is this going to be a problem, or will it be taken care of when I put thinset over it to lay the tile. This is obviously my first time laying tile.On a side note, when laying slate, is it best to use thinset or medium set, I've heard conflicting opinions.

- If you use medium set, any differences in the scale you described can be corrected fairly nicely.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiber Cement board for villas,high building-003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords