Exposed Suspension Ceiling Tee Grid /Bar System

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Flat Suspension Grids) Description

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

2,Main Features of the (Flat Suspension Grids)

Shape:Plane,groove

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized steel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic cold roll forming and punching machineries guarantee the high precision.

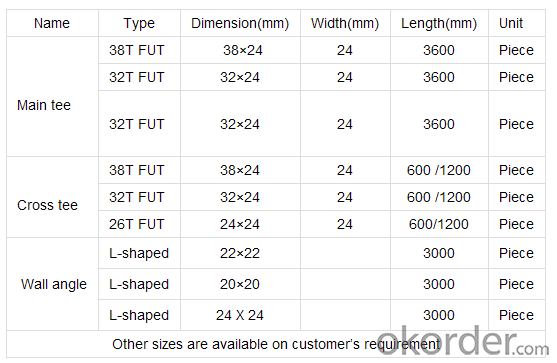

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

3,(Flat Suspension Grids) Images

4,(Flat Suspension Grids) Specification

5,FAQ of (Flat Suspension Grids)

1. Convenience in installation, it shortens working time and labor fees.

2. Neither air nor environment pollution while installing. With good effect for space dividing and beautifying.

3. Using fire proof material to assure living safety.

4. Can be installed according to practical demands.

5. The physical coefficient of all kinds Suspension

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

- Q:What are the meanings of the letters in the CB, DB CS, DF DM of the light steel keel? Seeking different people to explain ah

- CS: C-type superior keel, should refer to the ceiling 60 bearing keel: 60 * 27 * 1.2, DF: ceiling cover keel or ceiling vice keel or ceiling to pay keel anyway are covered keel, DM is the main keel (main) The ceiling carries the keel

- Q:What are the types of light steel keel skeleton?

- The main dragon has 38.50.60 what model can be scheduled

- Q:the kind meant for office and school ceilings that fit in a ceiling grid(4, t8 tubes), i was thinking of using 4, 8 inch jack chains and securing it with s hooks and eye hooks. is this alright or will i have to find another way? I'm using #10 eye hooks and 1 s hooks.

- Yes, you can suspend them with jack chain and eye hooks. I installed literally thousands of those lights (we called them troffers when I was a commercial electrician. In fact, in most cases even if we were dropping them in the grid for main support we also had to suspend two or four ceiling tie wires or jack chain supports to each fixture for earthquake security.

- Q:T-type light steel keel tb24 * 38 what does it mean

- T-type is not on the person, the width of 24mm, height 38mm is the T-type main keel

- Q:Double-sided 200 light steel keel gypsum board wall how much money a square

- Use 150 light steel keel, double-sided double-layer 12mm gypsum board, do paint, you can reach 200mm specifications.

- Q:1 square light steel keel ceiling keel consumption coefficient how to count it

- A square light steel keel ceiling generally need the main keel: 1 meter, vice keel: 2.5-3 meters.

- Q:Light steel keel and wood keel ceiling which is better?

- Light steel keel ceiling 1, the selection of light steel keel should meet the design requirements to ensure quality. 2, all in the ceiling of spare parts, keel should be galvanized pieces. 3, keel, boom, connectors should be the right position, the material formation, straight, connected firmly, no loosening. 4, where the suspension of the bearing parts must increase the horizontal keel. 5, the boom from the main keel end shall not exceed 300mm. 6, the quality of the standard deviation can refer to the wooden ceiling. Aluminum alloy keel ceiling decoration quality how to check, can also refer to light steel keel ceiling

- Q:Light steel keel performance and use

- Most used in the ceiling! Light steel keel, the surface after the heat crossing zinc treatment

- Q:Is it nice to use a light steel keel or a wooden keel?

- Light steel keel is good, wood keel will be hair enzyme, but the price is cheaper than the former

- Q:Known floor building elevation, ceiling elevation, light steel keel gypsum board ceiling boom length how to calculate?

- Depends on the height of the room and the spacing of the boom

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Exposed Suspension Ceiling Tee Grid /Bar System

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords