Environmental friendly halogen-free TPU compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TPU raw materials:

1. various kinds

2. competitive price

3. 30 years of experience

4. stable quality

TPU raw materials:

1. Applications and cable specifications of TPU raw materials:

Used for water-resistant power cables, data cables, and spring wire.

2. Description of TPU raw materials:

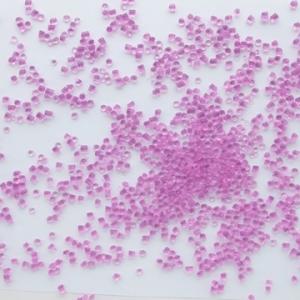

Environmental friendly halogen-free TPU cable compound, based on TPU elastomer resin, is made into granules by mixing, plastification and granulation with adding special modifier and other special additives. It has well performance of tenacity, scratch-resistant, flexibility, Stretch Resistance, and temperature resistance, owning exquisite appearance and smooth surface. It does not contain halogens and heavy metal, in line with the environmental directives of RoHS, REACH. Different hardness can be customized according to customers’ requirements.

3. Processing of TPU raw materials:

The compound can be processed with conventional extruders. It is recommended that the screw L/D should be greater than 25 and compression ratio should be 1:2.5.

The following temperature(°C) profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Neck | Head | Die |

temperature °C | 150 | 170 | 155 | 175 | 178 | 178 | 175 |

Note:Compound should be dried at 80-90°C before use, which has stayed in storage more than one month.

4. Storage and transport of TPU raw materials:

Packaging:25kg/bag,Aluminum foil and PE film bag inside, and PP compound bag outside.

Storage and transport: Avoiding in direct sunlight and weathering. The storage should be clean, cool, dry, and ventilated.

5. Properties of TPU raw materials:

Item | Unit | E7385 | E8385 | E8685 | E8685F | ||||

Standard | Typical | Standard | Typical | Standard | Typical | Standard | Typical | ||

Density | g/cm3 | -- | 1.19 | -- | 1.21 | -- | 1.28 | -- | 1.27 |

Hardness | Shore A | -- | 85 | -- | 85 | -- | 85 | -- | 85 |

Tensile Strength | ≥MPa | 18 | 22 | 22 | 28 | 20 | 25 | 20 | 24 |

Elongation at Break | ≥ % | 550 | 700 | 500 | 650 | 500 | 650 | 450 | 600 |

Thermal aging | °C*h | 136°C*168h | 136°C*168h | 121°C*168h | 121°C*168h | ||||

TS retention | ≥ % | 75 | 103 | 75 | 105 | 75 | 104 | 75 | 102 |

EB retention | ≥ % | 75 | 81 | 75 | 84 | 65 | 89 | 65 | 86 |

Hot deformation | 150°C*4h | 150°C*4h | 150°C*4h | 150°C*4h | |||||

Variation on thermal deformation | ≤ % | 50 | 12 | 50 | 7 | 50 | 6 | 50 | 6 |

pH value of gases released | ≥ | 4.3 | 56. | 4.3 | 5.3 | ||||

Conductivity of Gases released | ≤μm/mm | 10 | 1.2 | 10 | 1.3 | ||||

Impact Brittleness Temperature | ≤ °C | -60 | Pass | -55 | Pass | -50 | Pass | -50 | Pass |

Volume Resistivity, at 20°C | ≥Ω*m | 1.0×1012 | 2.1×1013 | 1.0×1013 | 5.2×1014 | 1.0×1013 | 3.4×1014 | 1.0×1013 | 1.8×1014 |

Flame retardant grade | UL94 2mm | V0 | pass | V0 | pass | ||||

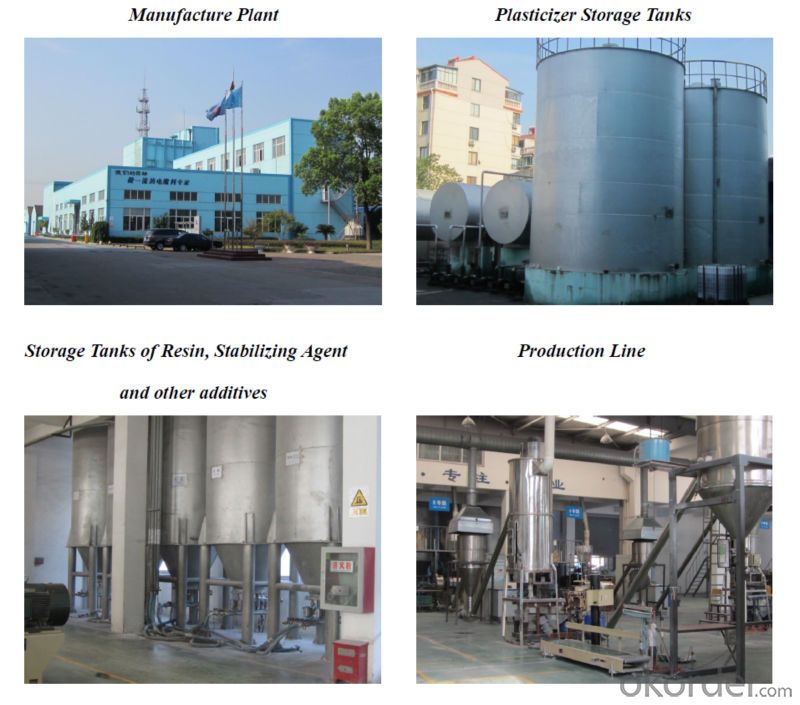

6. Company

- Q:What's the difference between recycled plastic bucket and plastic bucket made of raw material?

- What's the difference between recycled material and plastic bucket? Some plastic barrels are more white, and some plastic barrels feel transparent color, darker color. They say it's made of raw materials.

- Q:What is the concept of plastic raw materials for turnover containers?

- Plastic turnover box, other features: 1) plastic turnover box outer dimension refers to the maximum size of the logistics box cover. 2) the plastic turnover box has no standard inner concave, and the case size is 18mm. 3) the carrying capacity of a plastic turnover box means that the load is uniformly placed within the range of the environmental temperature. 4) the effective working temperature of the plastic turnover box is -25 DEG C - 40 DEG C. 5) plastic turnover boxes can be stacked for storage, saving space.

- Q:Do you have plastic materials that are low in price instead of ABS?

- The hardness is the same as that of ABS. H series PP contains nucleating agent. The hardness of PP after crystallization is 30% higher than that of ordinary PP, 110R is 109R, and the hardness of ABS is

- Q:Dissolve in 0.3 of the LDPE plastic raw materials what?

- Low density polyethylene (Low density polyethylene, referred to as LDPE) is usually based on ethylene monomer in high pressure 98 ~ 294MPa, with oxygen or organic peroxide as initiator, the polymerization of the polymer, the density of 0.910 ~ 0. 9259/cm3. medium density polyethylene (MDPE) density is 0.926 ~ 0.9409/cm3; very low density polyethylene (VLDPE) density below 0.910g/cm3.

- Q:What kind of raw material is plastic hollow board made of?

- Plastic hollow board is non-toxic, tasteless, moisture proof, corrosion resistance, light weight, beautiful appearance, rich color, pure, and has anti bending, anti ageing, anti tensile, compression and tear strength of higher performance, according to user needs, the production of plastic hollow plate thickness is 2-7mm, the width is less than or equal to 2.3m, no length limit. Ordinary hollow plate, hollow plate, anti-static and flame retardant conductive hollow plate hollow plate.

- Q:What kind of plastic material is used for medical instruments?

- You need to add various additives in plastics processing or modification process, such as in the PVC medical products in the amount of the plasticizer is as high as 30 - 60%, so as far as possible the use of non-toxic additives, long-term use to prevent or reduce the additive precipitation, so as not to affect the product performance and the therapeutic effect;

- Q:Main ingredients and formulations of PPR tubes

- PPR pipe has energy saving, environmental protection, high strength, corrosion resistance, with smooth inner wall has the advantages of scale, construction and easy maintenance, long service life, widely used in building water supply and drainage, urban drainage, city gas, electric power and cable sheath, industrial fluid transportation, agricultural irrigation, industrial and municipal construction industry and the field of agriculture. The PP-R pipe is made of random copolymerized polypropylene and is extruded into tubes to be molded into tubes.

- Q:What can be added to the PP plastic material to prevent light transmission?

- PP material suppliers to remind you, PP plastic raw materials to add sunscreen, adding black masterbatch or impact PP raw materials on the line

- Q:What is the raw material for producing high temperature polyethylene plastic bags?

- In the process, 2% montmorillonite can be added, which can significantly improve the thermal stability and tensile properties. For specific methods, please refer to the relevant literature.

- Q:Pollution in the production of plastic raw materials from petroleum production

- Oil separates compounds of different components by distillation. Through this process, liquefied gases (alkanes, olefins, etc.), diesel, gasoline, bitumen, etc. (from gas to solids) can be separated. In addition, plastic monomers can be prepared from naphtha or natural gas in synthetic plastics

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Environmental friendly halogen-free TPU compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords