Edge Banding Machines of Different Kinds,PANEL SAW

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Edge Banding Machines-Panel Saw Description

A panel saw is any type of sawing machine with a sliding table that cuts sheets into sized parts.

A sliding panel saw was invented by Wilhelm Altendorf in 1906 in Germany. Its invention set a new standard in woodworking, with dramatic differences from traditional machines. Up to that time, a conventional table saw had no mechanism for edging. Meaning that for the first and second longitudinal cut on untreated massive wood, the lumber always had to be fed manually through the saw blade. The new system accomplished the task more elegantly by allowing the work piece to be fed through the saw blade while lying on a sliding table. Thus cutting becomes faster, accurate and effortless.

Main Features of Edge Banding Machines-Panel Saw

Panel saws are used by cabinet shops to easily cut panels, profiles, solid-wood, MDF, laminates, plastic sheets and sheets into sizes or cabinet components. They are also used by sign shops to cut sheets of aluminum, plastic and wood for their sign blanks. Some higher end panel saws feature computer controls that move the blade and fence systems to preset values. Other lower end machines offer simplicity and ease of use, including full scale hobbyist level panel saws at a mere fraction of the cost. While the entry level machines are designed for light duty usage, they offer home DIYers a cheap alternative for infrequent cutting when accuracy and clean cuts are not required.

Panel saws can have one main saw blade, or a scoring along with a main saw blade. Scoring is used to create a groove, especially in double side laminate before the main saw rips the piece apart, to avoid chipping. The scoring saw rotates in an opposite direction, as the main saw to avoid chipping.

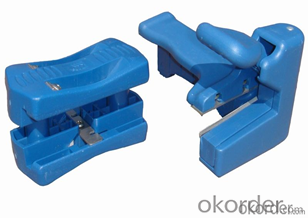

Edge Banding Machines-Panel Saw Images

Edge Banding Machine-Panel Saw Specifications

Maximum cutting length2800mm2800mm

Maximum cutting thickness80mm80mm

Main Blade sizeΦ305×Φ30mmΦ305×Φ30mm

Slot Blade sizeΦ120×Φ22mmΦ120×Φ22mm

Main saw shaft speed4000/5000rpm4000/5000rpm

Slot saw shaft speed9000r/min9000r/min

Main saw motor power5.5kw4kw

Slot saw motor power1.1kw1.1kw

Total power6.6kw5.1kw

Suction mouthΦ100×1Φ100×1

Weight800kg770kg

Box set dimensions3400×1150×1100mm3400×1100×1100mm

FAQ of Edge Banding Machines-Panel Saw

1) What can we do for you?

.We can ensure the quality of the Edge Banding Machines-Panel Saw and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q:How do you close the wallpaper?

- It doesn't have to be sealed. If you want to seal it, anything is OK and the box is ok.Of course, the nail is the best. Glue and nails are usually used.Wallpaper construction process and construction technology1. grassroots treatmentPaste before, should be on the surface of the base substrate or dirt, clean the dust, efflorescence parts with dilute acetic acid and cleaning nine percent. The base may not have flying thorn, pitting, sand and cracks, yin and yang angle should be straight. The surface is smooth and sticky.After the grassroots cleaning, in the grass-roots to play putty, dry sandpaper polished.2. brush primerPaint with an environmental varnish, solution, etc on the base surface.3. part elastic lineFirst of all, the interior is facing indoor, dead angle, according to wallpaper width row, Yang Kok should be wrapped angle, overcast corner to overlap, and according to the plan to play the vertical line, and number marked, as a sticky line.4. cut paperAccording to the wall frame size, cut the paper according to the requirements on patterned wallpaper pattern, the corresponding number two, she set aside 30---50MM volume cutting, flat.5. brush adhesiveThe table will wipe the back cut wallpaper to flat, with a flat brush or roller coating, and press the upper 1/3, lower 2/3, rubber face rubber surface after folded into a cylinder by post. (ten, wall felt back glue, in order to avoid the pollution of positive. Glue only to the wall.).6, stickyThe brush glue after the wallpaper launched folding the top part of posts on the wall, along the vertical datum line (horizontal) post wall (ceiling), with a plastic scraper or brush to scrape out, and she bubble adhesive, with a clean towel to wipe seam wallpaper, wallpaper knife to cut the number she part.

- Q:Can there be less or no addition of lead stabilizers in the PVC banding? Is there a replacement? Because China's ROHS on lead, chromium, mercury, cadmium content requirements.Is it possible to produce edge banding products that meet the requirements of ROHS? Around Beijing

- Yes, we export products that satisfy ROHSGeneral manufacturers have substitutes.

- Q:How about Yongqiang sealing machine

- To tell you the truth, it's much worse than imports. Be bold to entrap, good machine, maintenance TMD too expensive.I have a few villagers with the edge of Qingdao yongqiang. How to say, next to a wheel old plate factory to repair 2 times. Finally, replace the parts. There is nothing wrong with the others.

- Q:What's the meaning of the "environmentally friendly edible wax" seal written on the wooden floor?

- The floor is wood pulp after treatment of wax exposed edges, is moisture-proof, not afraid of water.

- Q:Do you have an edge seal for each contract?

- Yes, to prevent forgery. The edge chapter is the most difficult to counterfeit, some people can judge the seal height, according to mark depth of power, is sealed in what circumstances. In the same place stamp, different people, the effect is not the same,

- Q:How should the reinforcing rib of the reinforcing bar of the cap be arranged?

- Just like the bottom bar end housing, in cap around layout, general single two-way reinforced net

- Q:What are the specifications of the side reinforcement in the raft edge construction? With gluten or gluten? Or using smaller steel bars?

- There are three kinds of edge sealing structures on the side and side of the plate foundation plate. One is the longitudinal reinforcement edge side edge structure, the other is the U rib structure edge banding way, and the three is the edge edge of the plate without the edge sealing structure, and the two is the edge structure of the plate edge.Many lateral reinforcing bars are of diameter 14mm or 16mm. The diameter and quantity of the reinforcement in the side structure are directly related to the thickness of the raft and the two-way main reinforcement

- Q:This is the following plate, do not want to use PVC or aluminum edge, too ugly, there is no paint or putty kind of things, can maintain wood color better?Ash integrated plate edge treatment, do not scratch putty directly do varnish okay?

- Mongolian pine Oh, Hei hei do not need to deal with it

- Q:I want to know how to use the veneer to seal the edges. The bark is 0.6MM. Is it made by hand or by the machine?

- It's better in quality, but not as good in appearance as the machine. It's not that good. In fact, it is recommended to use manual.

- Q:I am a furniture factory, need a lot, it is best to paint to dry is the best, the ash inside the shop, if the dry time is too slow for local repair will be dust, it will look at the dust, affect the quality of the product.

- Just with the paint, after the repair is finished, wipe with banana water, and it will be beautiful after natural drying.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Edge Banding Machines of Different Kinds,PANEL SAW

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords