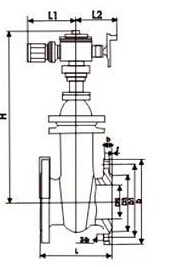

DN200 Cast steel Gate Valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Soft seal gate valve

Size:DN40mm-600mm

Design standard: DIN 3352/BS 5163/AWWA C509/JIS B2043

Test standard: DIN3230/BS 6755/AWWA C509/JIS B2003

End flange standard: DIN 2533 PN16/BS 4504 PN16/ANSI 150LB/JIS B2212 10K

Face to face standard: DIN 3202 F4/DIN 3202 F5/BS 5163/ANSI 16.10/JIS B2002

Body: Ductile iron/GGG50/A536

Wedge: Ductile iron+EPDM/Ductile iron+NBR

Stem: Brass/SS416/2Cr13

Bonnet: Ductile iron/GGG50

Handwheel: Ductile iron/GGG50

The products are widely used in water source projects, urban water supply and drainage, sewage treatment, eletric power, petroleum, petrochemical, heat supply, shipbuilding, medicine and metallurgy industries. Equipment are used for regulating or cutting off media in pipelines. Suitable media include water sewage, sea water, air, foodstuff and oil. Suitable for gear operators, electric and pneumatic control actuators.

- Q:What does gate valve do?

- Valve in the pipeline can only be fully open and fully closed off, can not be adjusted and the throttle. Gate valve is a valve used in a wide range, generally more than 50mm caliber DN block device is selected it, sometimes cut off very small aperture devices are used to gate valve, gate valve is used as cut-off media, when in full flow through the whole, when the media is running a minimal pressure loss. Gate valves are normally used in situations where they do not need to be frequently opened and closed, and the gate is fully open or fully closed. Not used as an adjustment or throttling. For high speed moving medium, the gate can cause the vibration of the gate under the condition of partial opening, and the vibration may damage the sealing surface of the gate and the valve seat, while throttling will cause the gate to suffer the erosion of medium.

- Q:About fire valve is gate valve or butterfly valve problems?

- Disease is generally in accordance with the design requirements, regardless of the butterfly or tie hair to meet the requirements, are two-way valve.

- Q:What are the structural differences between parallel and wedge valves?

- The double gate is pushed aside so that the sealing surface of the valve gate is tightly sealed with the valve body. These double gate parallel gates are mostly used on low pressure pipelines such as small pipelines. Parallel gate valves are also available with single gates, but are rare.That the sealing surface has a certain angle with the vertical center line, bearing higher medium temperature valve, angle the greater the possibility to reduce the temperature when wedged gate rice.Wedge gate valve single, double all.

- Q:Valve flange drawing n- up to what

- A bolt hole used to indicate a flangeThe value of N indicates the number of bolt holesUp to the numerical representation of bolt hole size

- Q:How to distinguish between gate valve and cut-off valve?

- Standard light valve professionals to answer for you, gate valve refers to the closure of parts (gate) along the central line of the vertical direction of moving valve. The gate valve is mainly used for cutting in the pipeline. The valve is a valve with a very wide, cutting device general caliber DN = 50mm use it, sometimes a small diameter cutting device also use valve, gate valve has the following advantages:Fluid resistance is small.Minor force needed for opening and closing.Medium flow is unrestricted.When opening fully, the sealing surface is eroded by the working medium smaller than the cut-off valve.

- Q:What is the difference between the copper gate valve and the ordinary material gate valve?!

- The copper gate valve is made of copper alloy, and the common materials are made of stainless steel, cast steel, cast iron, and so on. Now there are new types of ceramic gate valves. Different properties of the gate valve performance, processing technology, service life, applicable occasions are a certain difference. Copper gate valves should be used for fire end water outlet installations as well as other occasions with special requirements.

- Q:What are the differences between the gate valve and the cut-off valve?

- Is the gate valve opening and closing parts, RAM direction of motion perpendicular to the direction of the fluid, valve can only be fully open and fully closed, is not suitable for regulation and throttle. The gate has two sealing surfaces. The two sealing surfaces of the most commonly used wedge gate valves form a wedge. The wedge angle varies with valve parameters, usually 5o. Wedge gate valve can be made into a whole, called the rigid gate; can also be made to produce micro deformation of ram, in order to improve its process of deviation, make up the sealing surface angle in the process, the gate is called the flexible gate. Valve closed, the sealing surface can only rely on medium pressure to seal, that is to rely on medium pressure to the gate sealing surface pressure to the other side of the seat to ensure the sealing surface seal, which is self sealing. Most of the valve is forced seal, that is, when the valve closes, to rely on external force to force the gate to the seat, in order to ensure the sealing surface sealing.A stop valve is a valve that closes the valve and moves along the center line of the valve seat. According to this form of valve movement, the valve seat opening change is proportional to the valve stroke. Because of the valve stem to open or close the trip is relatively short, but very reliable cut off function, and because changes in the valve seat and the valve stroke is proportional, is very suitable for flow regulation. As a result, this type of valve is ideal for use as a shut-off or regulator and throttling

- Q:What are the meaning of the cast rigid gate valves z41h-16c?

- According to the provisions of the JB/T 308-2004 valve type programming method:Z== gate valve4== flange connection1== rigid single gateH== sealing surface material: Cr13 stainless steel16== pressure rating: 1.6MPaC== body material: carbon steel

- Q:The difference between flanged gate valve and common gate valve

- Flange gate valve and ordinary gate valve difference is that the flange gate valve of good quality, durable and easy to install, but the price is a little high, generally used for large pipelines. Common, also available, such as small caliber, easy to change places.

- Q:What is gate valve (with force transfer joint)?

- Double flange loose dowel joint is composed of telescopic joint and pipe flange, screw force transmission component, it can transfer the pressure thrust of the connecting piece (blind plate force) and error compensation line, cannot absorb axial displacement. Broad water supply, I hope to help you!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

DN200 Cast steel Gate Valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords