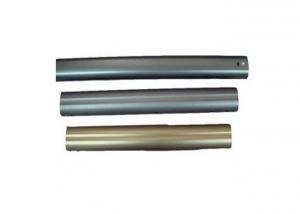

Custom Aluminium Shaft Products Manufacturer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Piece pc

- Supply Capability:

- 5000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1)Japanese standard

2)Max. precision 0.005mm

3)Mainly export to Japan

4)aluminium shaft

5)Custom service

Material available |

|

Carbon Steel | Stainless Steel 304/314/316 etc |

Tool Steel | Aluminum 2024/5052/6061/7075 |

Brass/Copper/Bronze | POM/Acrylic/Plastic/Nylon |

|

|

Machining Service |

|

CNC machining | Lathe Machining |

Milling | Stamping and bending |

Precision Welding | Wire Cutting |

Fixtures and jigs |

|

|

|

Finish Available |

|

Polishing | Zinc/Nickel/Chrome Plating |

clear/black/blue anodizing, sandblast | black oxide |

powder coating | painting |

|

|

Features |

|

Strict QC and reliable quality | on-time delivery |

small order acceptable | custom service by drawing or sample |

|

|

Main Clients |

|

CANON, DENSO,OMRON,RICOH,MISUMI etc |

|

|

|

- Q:Know how to draw Broaches for involute internal spline parameters

- To pull or spline spline, spline parameter is of course laane for internal spline broach;There are many factors in designing broaches, such as machine tool chucks, maximum broaching length, dimension and so on;General to broach company can do, they know how to do, need what parameter will provide.The spline joint is composed of inner spline and outer spline. The internal and external splines are all multi tooth parts, the splines on the inner cylinder surface are internal splines, and the splines on the outer cylinder surface are external splines. Obviously, the spline connection is the development of the number of flat key connections. Splines are standard structures.

- Q:Hope to find a complex tool to do good enterprises, especially broaches do good, quality and Harbin first tool factory and other veteran manufacturers almost or almost no, but the price is relatively cheap, a lot of, thank you

- If the broach requires high accuracy. Find a good factory. If you are producing or looking for cheap private companies, you can use the same price difference.

- Q:CNC Lathe Feed base surface is floating, there is no good way to solve?

- With raw claws, or with two machine tools processing, a car base level, one to do the accuracy, try

- Q:Why don't carbon tools steel be used to make Broaches and gear cutters?

- Because of its hardness is too high, easy to crack, and if you do gear cutters and broaches, not only a few times will collapse.Therefore, Broaches and gear cutters must be cemented carbide.The carbon content of carbon tool steel is high, between 0.65-1.35%, and belongs to sub eutectoid, eutectoid or eutectoid steel. The carbon tool steel can get higher hardness and wear resistance after heat treatment, and the core has good toughness. The annealing hardness is low (not more than HB207), and the processing performance is good. However, when the working temperature reached 250 DEG C, the hardness and wear resistance of steel decreased rapidly, the hardness decreased to below HRC60, and the hardenability of this kind of steel was low. Larger tools can not be quenched (water quenched by 15mm), and when water is quenched, the hardness of the surface hardened layer differs greatly from that of the central part. Cause the tool to deform easily when it is quenched. In addition, the range of the quenching temperature is narrow and the temperature should be strictly controlled during quenching. Prevent overheating, decarburization and deformation.

- Q:Is there an expert who knows the broach?!

- A machine tool spindle broach mechanism, a spindle is in threaded inside a broach broach rod is connected with a rod, claw clamping device for clamping or loosening cutter, broach rod sleeve is provided with a force pushing device, force pushing device comprises a pushing rod and a wedge block, wedge block with double the inclined plane respectively a wedge-shaped groove and a push rod and inclined broach rod are wedged, to pull the rod with tight broach, forcing a push device component section shape is round, can keep dynamic balance and achieve good purpose of high-speed operation.

- Q:How to solve tooth strain of involute spline broach?

- Sharpening the front corner of the broach requires a re opening of the backlash if it is a new cutter

- Q:Is this a standard part, or is it only required to buy the finished products from other factories, or do you want to design and size it yourself?

- General milling machine seems to be a root screw, if the NC milling machine is pneumatic or hydraulic broach device. CNC accessories sold, the package should also have, but very expensive. Not interchangeable by different manufacturers. Structurally simple steel ball with broach claws.

- Q:Why is the tooth shape of broach oblique?

- The tooth is made oblique in order to make the broaching cutter tooth is smooth, continuous in withdrawing from participation in the cutting, does not appear at the same time the whole circle cutter tooth cut, and the exit, so as to avoid broaching in appeared in the process of broaching flickering phenomenon, so as to obtain good cutting surface, too to improve the service life of the broach broach. But make oblique to the high cost.

- Q:Microcrystalline stone tile for broach can open it

- The microcrystal surface will collapse

- Q:Machining center spindle broach can not reach the designated position, how to adjust?

- The spring mattress on the pull rod in the spindle is broken, so replace it all

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong,China |

| Year Established | 2012 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | North America South America Eastern Europe Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shenzhen,shenzhen shekou |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | Below 1,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Custom Aluminium Shaft Products Manufacturer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Piece pc

- Supply Capability:

- 5000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords