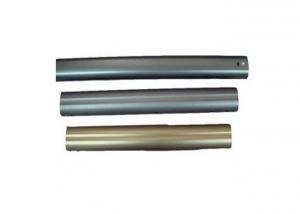

Extrusion Aluminium Parts for Luggage Case

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Pieces pc

- Supply Capability:

- 1000 Pieces per Day pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

Extrusion aluminium parts

1,Material:Aluminium alloy

2,Size:Do as your design

3,Usage:Luggage case

4,Finish:Color anodized

Extrusion aluminium parts for luggage case

Specification:

1,100% inspecification before shippment

2,Usage of luggage case

3,color anodized

4,extrusion

Advantage

1. Competitive price with good quality

2. Low MOQ (100pcs is even acceptable in some special conditions)

3. Short lead time (7-30days according to order qty)

4. Customized size and spec /OEM available

- Q:Know how to draw Broaches for involute internal spline parameters

- Are you going to pull the spline or external spline spline parameters is of course laane internal spline broach to do;There are many factors in designing broaches, such as machine tool chucks, maximum broaching length, dimension and so on;General to broach company can do, they know how to do, need what parameters will call you to provide

- Q:Hope to find a complex tool to do good enterprises, especially broaches do good, quality and Harbin first tool factory and other veteran manufacturers almost or almost no, but the price is relatively cheap, a lot of, thank you

- The tools of the Han River are made of broaches. What tool do you want, you can ask me.

- Q:CNC Lathe Feed base surface is floating, there is no good way to solve?

- With raw claws, or with two machine tools processing, a car base level, one to do the accuracy, try

- Q:5.6 small caliber gun rifling production line with much manual broach

- Hello landlord. The general value of deep rifling line diameter of the gun bore 2%. That is, 5.72 or 5.75 broaches, if conditional chromium plating. Just choose 5.8 broach. But the rifling twist wrapped angle is more complex, so please treat specific conditions. Please adopt

- Q:Ask, what does broach mean?

- Each department has its own general skills, general skills of broach is gold system, can increase the damage of broach,

- Q:Is this a standard part, or is it only required to buy the finished products from other factories, or do you want to design and size it yourself?

- Standard parts can be purchased. It is better to bring the old parts with them or to provide the corresponding machine tools

- Q:Why is the tooth shape of broach oblique?

- Because the broaching method of broach is done by layer by layer, the required inner spline shape is eventually machined out. Therefore, the blade of the broach is tilted from front to back

- Q:Pull the rifling when rotating or broach tube rotation or both rotation??

- The pipe is fixed and the cutter head can be taken into consideration with the percussion drill at the top of the drill bit, not knowing what exactly. Only know that grinding, and pull a tube, do not rub, do not change the knife!

- Q:Microcrystalline stone tile for broach can open it

- The microcrystal surface will collapse

- Q:I am currently in a lathe machinery factory, factory of broaching machine really curious.It is a hole with the kind of cylindrical broach broaching machine, after a day's work is down to a special knife Seurat with special machine tool grinding.Would you please tell me that the diameter of the broach is not smaller since he repaired it? Wouldn't it be possible to process the required size?

- Repair is the front edge of the broach, the blade has a wide blade. After grinding, only the edges become narrower and have nothing to do with the outer circle. Unless the grinding too much, will affect the outer diameter of the cutter tooth. However, the last 4-5 teeth of the broach are the correcting teeth for correcting the outer circle, so the sharpening broach has no influence on the final processing size.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong,China |

| Year Established | 2012 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | North America South America Eastern Europe Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shenzhen,shenzhen shekou |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | Below 1,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Extrusion Aluminium Parts for Luggage Case

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Pieces pc

- Supply Capability:

- 1000 Pieces per Day pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords