Corundum Bricks for Industrial Kilns and Furnaces

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Corundum Bricks for Industrial Kilns and Furnaces

Composite of Corundum Bricks

Corundum bricks use compact electro-smelted corundum and alumina powder as main raw materials, shaped under high pressure after machine-blending and fired at high temperature.

Main Features of Corundum Bricks

Low porosity

High compressive strength

Good chemical stability

Application of Corundum Bricks

Linings of high-temp industrial kilns and furnaces

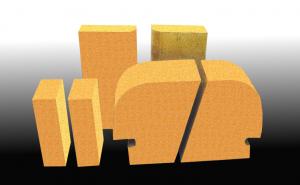

Corundum Bricks Images

Specification of Corundum Bricks

ITEM | GY-90 | GY-94 | GY-98 |

Al2O3, % | ≥90 | ≥94 | ≥98 |

Fe2O3, % | ≤1 | ≤1 | ≤0.3 |

Refractoriness, ℃ | ≥1790 | ≥1790 | ≥1790 |

Bulk Density, g/cm3 | ≥2.95 | ≥3.1 | ≥3.1 |

Apparent Porosity, % | ≤16 | ≤16 | ≤20 |

Cold Crushing Strength, Mpa | ≥80 | ≥80 | ≥60 |

Refractoriness Under Load (T0.6), ℃ | ≥1620 | ≥1650 | ≥1700 |

Permanent Lineat Change, % | 1500℃×3h,±0.2 | - | 1500℃×3h,±0.1 |

FAQ of Corundum Bricks

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories, at the same time, we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time, seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit, We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed, when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team, and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report, also we could apply other necessary certification.

Q8:How to solve the quality problems?

A:If the products are not confirmed to customer samples or have quality problems, our company will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of course, samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike. It also depends on your using condition and method.

- Q:What is the difference between corundum and high alumina?

- The main component of high purity 99 corundum brick is corundum sand,90 corundum brick is mainly composed of corundum sand and a small amount of Suzhou soil, mullite.

- Q:What refractory materials are adopted in each part of the blast furnace?

- Bosh temperature reaches 1600~1650, high alumina brick, corundum brick or silicon carbide brick. The upper hearth tuyere zone near the temperature at 1700~2000 Deg. C, the use of sillimanite brick, corundum and silicon carbide refractory filler, Shi Mozhi. Bottom temperature at 1450~1500 Deg. C, the use of graphite bricks and microporous carbon brick, now also used corundum brick, Gang Yumo brick and synthetic mullite brick.

- Q:Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- Fused zirconia corundum brick is pure alumina and zirconia containing silica 65%, about 34% of the zircon sand in electric furnace melting after internalization into moulds cooling and the formation of the white solid, the petrographic structure by zirconium corundum and plagioclase eutectoid and glass phases, from the phase is eutectoid zirconium corundum and plagioclase phase, glass phase filling between their crystallization.

- Q:How to improve the induction furnace campaign, from the promotion of refractory life start

- According to the use of atmosphere, choose the appropriate spraying materials, such as infrared radiation paint

- Q:Is liquid phosphoric acid two aluminum hydrogen flammable?

- Liquid phosphoric acid two hydrogen aluminum features: easy mixing, molding, especially suitable for field construction, so liquid phosphoric acid two hydrogen aluminum is not flammable

- Q:How much is a refractory brick?

- This question is too general, refractory bricks according to the use of the environment and industry, there are a variety of materials, a variety of specifications, prices vary greatly.

- Q:What are the refractory materials?

- Acid refractory with silicon oxide as the main component, are commonly used in brick and clay brick. Silica is silica containing more than 93% silica products, raw materials used in silica, silica and other waste, the acid resistance of slag erosion ability, high load softening temperature, volume shrinkage after repeated burning, or even a slight expansion; but it is vulnerable to the erosion of basic slag, low thermal shock resistance. The brick is mainly used for thermal equipment of glass furnace, coke oven, acid furnace etc.. Clay brick with refractory clay as the main raw material, containing 30% to 46% of alumina, weak acid refractory material, heat shock resistance, resistance to acid slag, widely used.

- Q:What does refractory consist of?

- Refractory materials can be divided into main raw materials and auxiliary raw materials according to their function in the production process of refractory materials.The main raw material is the main body of refractory. Auxiliary raw materials can be divided into binders and additives. The role of bonding agent is to make the refractory body in the production and use process has enough strength. There are commonly used lignin, phenolic resin, asphalt, cement, water glass, phosphoric acid and phosphate, sulfate, some main raw material itself has the effect of binder, such as clay; additive is to improve the production of refractory materials and construction technology, or strengthen the refractory material of some properties, such as stabilizer, water reducing agent, inhibitor, plasticizer, foaming agent, dispersing agent, bulking agent, antioxidant.

- Q:What are the main constituents of refractory bricks?

- Refractory brick composition is mainly composed of a variety of aggregate or aggregate and one or more kinds of sticky agent composed of mixed powder particles, when used, must be mixed with one or more liquids, mixing evenly, with strong liquidity. Different refractory bricks are different, such as silicon, aluminum, clay and so on:According to the composition of refractory bricks, they can be divided into five major categories, namely, silicon aluminum refractory bricks, basic series refractory bricks, carbon containing refractory bricks, zirconium containing refractory bricks and insulating refractory bricks. Any furnace is not made of only one kind of refractory brick, and it needs different fire bricks to match with each other. The following five categories of refractory bricks are described in detail.

- Q:What refractory materials are used in industrial furnaces?

- Refractory materials use high temperature function to master all kinds of refractory material function, especially high temperature use function. Selection should give full play to its advantages, and from the furnace structure, masonry and protection to overcome its shortcomings.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Corundum Bricks for Industrial Kilns and Furnaces

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords