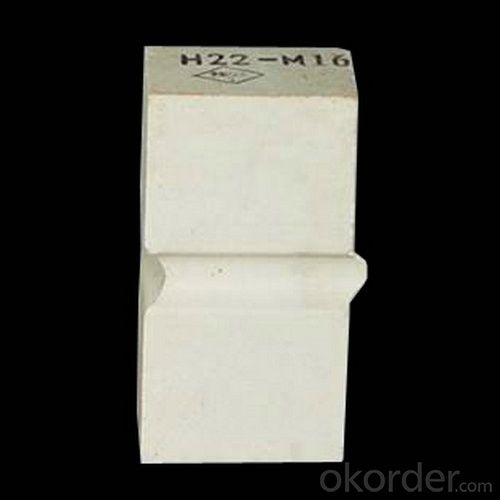

Fireproof Refractory Fire Brick Corundum Brick for High Temperature Ladle Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

What is the details of our fire brick corundum?

1.Corundum Brick contain more than 90% of aluminum oxide,which is manufactured using high quality synthetic electro-fused corundum and sintered corundum and finely grained highly aluminous raw materials with ceramic and chemical bonding.

2.Corundum brick is shipped under high pressure and fire with high temperature with scientifically and reasonably gradating and adding good performance of additives.

What is the Technique Data of our fire brick corundum?

Item | Corundum Brick 99 | Corundum Brick 90 | Corundum-mullite Brick |

Al2O3 % | ≥99 | ≥90 | ≥94 |

SiO2 % | ≤0.2 | ≤8 | ≤4 |

Fe2O3 % | ≤0.2 | ≤0.2 | ≤0.2 |

Bulk Density g/cm3 | ≥3.2 | ≥3 | ≥3.2 |

Apparent porosity % | ≤19 | ≤18 | ≤13 |

Cold compressive strength MPa | ≥100 | ≥100 | ≥100 |

(0.2Mpa,0.6%)Load softening began to temperature °C | ≥1700 | ≥1700 | ≥1700 |

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

- Q:What refractory materials are adopted in each part of the blast furnace?

- The lower part of the shaft due to high temperature and dust by scouring and alkali metal vapor erosion, so the requirements for the slag resistance, alkali resistance and high temperature resistance, wear resistance of high quality clay brick, high alumina brick, carborundum brick or corundum brick. Belly temperature reaches 1400~1600, and slag, steam erosion, erosion and corrosion is strong, therefore, the silicon carbide reaction bonded silicon carbide brick.

- Q:How to improve the induction furnace campaign, from the promotion of refractory life start

- Select suitable insulation materials, such as polycrystalline facing blocks and ceramic fiber modules, depending on the service temperature

- Q:What is the main component of corundum?

- Corundum is the main component of Al2O3, often containing trace impurities such as Cr, Ti, Fe, V and so on.

- Q:Which is good, glazed brick and whole cast glazed brick?

- The main advantages of all glazed glazed tiles are that they can be very rich and beautiful in texture and pattern, and they are suitable for family decoration, and can choose patterns according to their own family decoration style. Compared to the glazed tile, it has better pollutant discharge performance, and many pollutants are difficult to penetrate into it.

- Q:What kind of refractory material will be used in the glass kiln?

- The content of ZrO2 in the brick is about 66%, and the bulk density is 3.7g/cm3, which has better thermal stability and anti stripping property. The use of erosion serious investment outlet area and after the parapet wall in the powder melting furnace, observation hole brick and pathway of flame space and roof parapet wall brick, brick burner. But there are also AZS burner brick with mullite brick for brick kiln and transition two side clearance brick etc..

- Q:Can the PE sintering plate dust collector be suitable for dust removal in the coking plant?

- Do not know where the coking plant do dust treatment, processing conditions are different, the dust collector is not the same

- Q:High temperature refractory material?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, the refractory material used for special occasions.

- Q:What equipment is used for producing diamond blanks? How much is the investment?

- You'll have to invest about about one million if you want an electric furnace. A power distribution room is easiest to approach one hundred thousand. Electric furnaces, power distribution cabinets and transformers must be around one hundred and ten thousand.

- Q:What can zirconium sponge do for those industries?

- Uses: aerospace, military, nuclear reactions, atomic energy, and metal superhard materials, the manufacture of bulletproof alloy steel, can also be used in the reactor uranium fuel coating alloy; zirconium at high temperatures easy to launch electronicProduct characteristics: zirconium metal has very strong corrosion resistance, ultra high hardness and strength

- Q:What refractory materials are used in industrial furnaces?

- Economically, it is necessary to do technical and economic analysis when selecting materials reasonably. Under the premise that the technical indexes agree with the working conditions of the furnace, the refractory materials with low quoted price should be used as much as possible, without high-grade finished products. To think about whether to make self (such as irrigation, refractory concrete) as far as possible to repair old.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fireproof Refractory Fire Brick Corundum Brick for High Temperature Ladle Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords