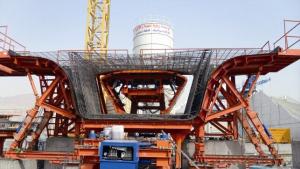

Construction Climb Mold Steel Formwork with high quality and competitive price

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 watt

- Supply Capability:

- 5000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM Climb Mold Steel Formwork

Product Introduction:

With the rapid development of urban rail transit project, the climb mold formwork is widely used in construction project. It have the advantages of noise-reduction good effect, low building height, high space utilization and good appearance.

With the progress of technology, construction method changes from cast-in-place to precast hoisting.

Specification:

Precast U-Beam formwork structure: outer side formwork, inner formwork, bottom formwork, support lead screw, JACK, work platform, Vibrator, crawling ladder, blanking plate etc.

Main products covers:

U-shaped beam

Segmental beam

Climb mold

Integrated pipe gallery

Automatic Prefabrication culvert

Shaped pier

T-beam

Alien template

Applied formwork Project:

Our products capacity:

More than 3 state grade certificates

More than 40 patents

More than 10 series main products

More than 10 government and project awards

WORKSHOP & EQUIPMENT:

Technology

We offer on site consultation and safety advice to help our customers work safely and improve productivity in each project.

CNBM combines its staff experience with advanced CAD systems and self-developed software to do this job to better meet the market requirements.

FAQ:

1. What we need for formwork design and make proposal?

Please offer the project drawing, CAD drawing for making design accurately.

2. How fast can the order be delivered?

Please kindly state your desired Delivery date for the order. The order and the desired delivery date will be checked after your order got sent. Of course, we will try our best to meet the specified delivery date.

3. What's the material of the products?

Steel Q235B or Q345B.

- Q:Why is Changshi beam, but also computing to the side or side column beam?How to deduct the overlap area between beam and plate, column and wall, wall and wall

- The connection between the column and the beam and the place where the beam is connected with the beam does not need to be deducted from the area.

- Q:The calculation formula of the beam column for the construction of the concrete and the use of the template area of the detailed point of the best thank you

- Refer to JGJ 162-2008 construction formwork safety technical specifications

- Q:What is a large volume template? How much is the cross section of the beam, belonging to the large volume template?

- For the height of more than 8m, the total load is greater than 15kN/m2, or the central line load greater than 20kN/m of the template support system needs to organize expert demonstration".

- Q:What are the main composition of the beam template

- D> suspended beam formwork support composite structure A> roof formwork support composite structure consists of main beam (main dragon's back), auxiliary beam (vice dragon), support rod, cross bar composed of B> shear wall formwork supporting structure.

- Q:Is there a beam plate template that is used to calculate the engineering quantity of the beam formwork or the engineering quantity of the beam and the plate? Urgent thank you

- If you read the instructions in the quota, it will be fruitful

- Q:First of all, what are the construction of the structure of the template, such as walls, columns, beams and ladders, which is the structure of the first installation of the template after the installation of steel? Ten

- Who told you that?. Shear wall, column is the first binding steel, and then close the template, if the two sides of the shear wall formwork and the death of the death of the column template, but also how to bind and connect steel

- Q:How to do the foundation beam template

- Construction sequence: the structure of the column to tie the tendons to the skin of the number of poles to wall masonry before the first floor on the ground has been played by the large axis of the wall body axis and the line. The surface of the base should be clean and wet. When you start the masonry, the brick should be placed and the seam width should be discharged. In the walls before the first vertical skin pole pole, skin should be marked with each skin brick and mortar joint thickness, lintel ring, position, number of rod should be set up in the skin of the building end corner, wall aspect junction and interior wall. Masonry should be up and down the wrong seam, inside and outside the lap, gray seam straight full, the level of gray seam thickness and vertical ash seam width should be controlled at around 1-1.1cm

- Q:For example, the 0.14 long girder thick 400x600 26 how to calculate the amount of engineering template

- According to the calculation of the expansion area, the height of support according to the bottom elevation

- Q:When there is a beam plate template, the beam can not be added to the template?

- Beam template and foundation beam template to separate sets of fixed!

- Q:There are times when the beam is not to deduct the secondary beam on the main part of the beam?

- The bottom of the beam is provided with two side edges, and the side edges are counted to the bottom of the plate

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Construction Climb Mold Steel Formwork with high quality and competitive price

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 watt

- Supply Capability:

- 5000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords