Convenient Efficient Girder Box Formwork With Timber Beam

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

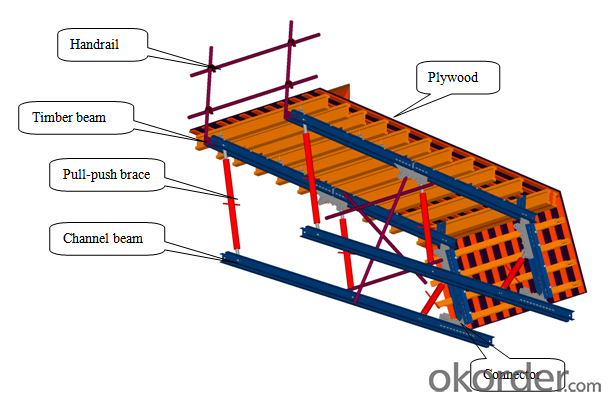

1. CMAX Girder Box Formwork System Description

GB system-A is a kind of formwork especially for the bridge floor construction.

2. Main Features of CMAX Girder Box Formwork System

- Prefabricated connection, convenient and efficient.

- Light weight but high bearing capacity.

- Timber is easy resized, so the Tim-formwork is relatively easier to change self’s size and shape. This approved formwork’s economical efficiency.

3. CMAX Girder Box Formwork System Application

4. FAQ of CMAX Girder Box Formwork System

1) What can we do for you?

- We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

- We can provide you the professional design team.

- We can provide fashionable and newest styles for you.

- We can design the artwork for you.

- Please feel free to customize.

2) What promises can be done by us?

- If interested in Timber-beam Formwork, please feel free to write us for any QUOTE.

- If printing required, please advise asap because the whole set need much more time to complete.

- Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about the package and shipping time?

- Packing: As Customer's Requirements

- Shipping: We have various shipping ways for our customers, such as express, by air/ sea etc.

- Shipping time: Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

- Q:How to control the elevation of the beam bottom and the axis position

- The design of the middle arch ratio is higher than the span of the span of 1--2 thousandths of 2. A template, according to the control point set square.

- Q:What kind of frame beam formwork

- Frame beam template, single beam, continuous beam template section, beam set beam template in the middle section.

- Q:The bottom of the board 12.24*7.44 why not *2 floor 12.24 of the two of the 7.44 also have the plate side mode *2 is * of the two or both

- Figure is too small, the eyes are looking at flowers.1, floor 12.24*7.44 is the bottom of the whole plate (including the bottom of the beam), and then subtract the column area. Board only need to calculate the bottom and side die on the line, do not use *2.

- Q:How to support 6m arc beam template how to set up?

- If you use a supporting beam of radian template, the bottom surface made of a whole block template (template block with good reinforcement, pouring backwater) after dismantling the entire arc shape template on the line; if the second half of the same radian can do a whole half arc template do the bottom die.

- Q:The calculation of formwork engineering quantity of ground beam needs to calculate the bottom of beam

- Slowing down the negative effect of uneven settlement. There are difference and ring beam (beam) foundation beam mainly links, enhance the level of rigidity, sometimes used as underfill supporting beam wall, without considering the seismic effect.

- Q:Which part of the middle beam and side beam in the T beam template? Thank you

- So there are [side span beam], [cross the middle beam], [medium span beam], [across the edge beam] four kinds of distinction. The amount of concrete, steel is a little different

- Q:More than the number of square cross-section of the beam high formwork

- According to the "dangerous method" sub project safety management of the construction quality of [2009]87, the height of more than 5m, the total construction loads greater than 10kN/m2, or the template support system concentrated line load greater than 15kN/m to prepare special construction scheme

- Q:When there is a beam plate template, the beam can not be added to the template?

- Beam template and foundation beam template to separate sets of fixed!

- Q:Beam column plate template how to calculate the need to deduct what part?

- A method is relatively simple and practicalThe calculation formula of the first column is the circumference multiplied by the height of the unit is M2

- Q:When the main beam and secondary beam connection, calculate the area of the template is good, there is no simple method

- From the main beam to break, that is, the secondary beam axis to the axis of the long axis of the main axis of the beam to reduce the length of the beam width

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Convenient Efficient Girder Box Formwork With Timber Beam

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords