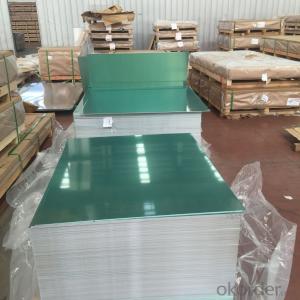

coated aluminium coil AA3003-H16, 0.62mm thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Aluminum coils color coated are of a wide range of colors, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

Aluminum coils color coated have been widely used in the fields of construction and decoration, electronic applications, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

2.Main Features of the Aluminum Coils Colored Coated

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

4.Aluminum Coils Colored Coated Specification

Width 30mm-1700mm

Coating PE,PVDF,Epoxy

Painting Thickness Standard 16-25 Mic, max 40 Mic

Color According to RAL colors or customers' samples

Standard GB/T 17748-1999

- Q:What is the flexural modulus of aluminum sheets?

- The measure of the stiffness or rigidity of aluminum sheets when subjected to bending or flexural stress is referred to as the flexural modulus. This mechanical property quantifies the aluminum sheet's resistance to deformation under applied force. Typically ranging between 69 GPa to 79 GPa, the flexural modulus of aluminum sheets depends on the specific alloy and temper. However, it is crucial to note that factors such as thickness, heat treatment, and manufacturing processes can cause slight variations in the flexural modulus. Aluminum is widely recognized for its exceptional strength-to-weight ratio, making it a favored choice for applications that require lightweight and durable materials. Due to its relatively high flexural modulus, aluminum sheets can maintain their shape and resist bending or flexing, making them suitable for uses in aircraft structures, automotive components, and building construction. It is important to highlight that the flexural modulus of aluminum can be improved through alloying elements or heat treatment processes. For instance, certain aluminum alloys like 7075 or 2024 may exhibit higher flexural modulus values due to their enhanced strength and stiffness properties. To summarize, the flexural modulus of aluminum sheets is a crucial mechanical property that determines their ability to withstand bending or flexural stress. This property provides valuable insights into the material's rigidity and assists engineers and designers in selecting the appropriate aluminum alloy and thickness for various applications.

- Q:What are the different types of aluminum sheets?

- The different types of aluminum sheets include plain aluminum sheets, embossed aluminum sheets, perforated aluminum sheets, painted aluminum sheets, and brushed aluminum sheets.

- Q:I am doing some exam review and do not know how to do these...Calculate the number of Nitrate ions in 3.99 g or aluminum nitrate.

- OK - first you need the ENTIRE mass of the aluminum nitrate (gram formula mass). You need the correct formula for aluminum nitrate, then add up the atomic masses from the periodic chart. Then, you need to convert 3.99 g of aluminum nitrate to moles of aluminum nitrate. (grams/formula mass = moles) Then, you need to take into account how many moles of nitrate ions are in a mole (look at the correct formula for aluminum nitrate). Then multiply by the number of moles you calculated (moles of ions per molecule x #moles). This would be moles of ions. You need individual ions you would the multiply by 6.02 x 10^23 ions/mole. SO: grams of sample divided by formula mass x #nitrate ions per molecule x (6.023 x 10^23 ions per mole) = # ions

- Q:Are aluminum sheets suitable for pharmaceutical applications?

- Aluminum sheets are well-suited for pharmaceutical use, as they possess a range of advantageous properties. Firstly, their lightweight nature and exceptional resistance to corrosion make them an ideal choice for packaging pharmaceutical products. By shielding the contents from external factors like moisture, light, and oxygen, which could potentially compromise the medication's quality, aluminum sheets offer excellent protection. Additionally, aluminum sheets are highly malleable and can easily be molded into different shapes and sizes, allowing for customized packaging designs. Moreover, their availability in various thicknesses provides options for different types of pharmaceutical products, including tablets, capsules, and liquid medications. Furthermore, aluminum sheets boast a remarkable barrier property that effectively prevents the transfer of odors, flavors, and contaminants. This barrier ensures the integrity and safety of the medication throughout its entire shelf life. Furthermore, aluminum is a non-toxic material, guaranteeing that it does not react with drugs or alter their composition. This quality makes it an optimal choice for pharmaceutical applications, where maintaining the purity and stability of the medication is of utmost importance. In conclusion, aluminum sheets are highly suitable for pharmaceutical applications, thanks to their lightweight nature, corrosion resistance, barrier properties, and non-toxic composition. By efficiently safeguarding and preserving pharmaceutical products, they ensure the quality and safety of these crucial medications.

- Q:How do you calculate the weight of an aluminum sheet?

- To calculate the weight of an aluminum sheet, you need to consider its dimensions (length, width, and thickness) and the density of aluminum. First, measure the length, width, and thickness of the aluminum sheet in inches or millimeters. Make sure to use the same unit of measurement throughout the calculation. Next, convert the dimensions to feet or meters if necessary. For example, if the dimensions are in inches, divide each value by 12 to convert it to feet. Multiply the length, width, and thickness together to find the volume of the aluminum sheet. If the dimensions are in different units, convert them to the same unit before multiplying. Then, look up the density of aluminum. The density of aluminum is approximately 2.7 grams per cubic centimeter or 2700 kilograms per cubic meter. Convert the volume of the aluminum sheet to the same unit as the density. For example, if the density is in kilograms per cubic meter and the volume is in cubic feet, convert the volume to cubic meters by multiplying it by 0.0283. Finally, multiply the volume of the aluminum sheet by the density of aluminum to get the weight of the sheet. The result will be in grams or kilograms if the density was in grams per cubic centimeter, or in kilograms or metric tons if the density was in kilograms per cubic meter. It's important to note that this calculation assumes a uniform thickness throughout the aluminum sheet. If the sheet has varying thicknesses, you would need to calculate the weight of each section separately and then sum them up to find the total weight.

- Q:Are aluminum sheets suitable for laser cutting?

- Yes, aluminum sheets are suitable for laser cutting.

- Q:Are aluminum sheets resistant to staining?

- Yes, aluminum sheets are resistant to staining. Aluminum has a natural oxide layer that forms on its surface when exposed to air. This oxide layer acts as a protective barrier, preventing staining and corrosion. However, it is important to note that prolonged exposure to certain chemicals or acidic substances can still cause discoloration or staining on aluminum sheets. Regular cleaning and maintenance are recommended to preserve the appearance and longevity of aluminum sheets.

- Q:Are aluminum sheets suitable for aerospace structural components?

- Yes, aluminum sheets are suitable for aerospace structural components. Aluminum is a lightweight and durable material that has been widely used in the aerospace industry for many years. It possesses excellent strength-to-weight ratio, making it highly desirable for various applications in aircraft manufacturing. Aluminum sheets offer several advantages for aerospace structural components. Firstly, they are lightweight, which helps reduce the overall weight of the aircraft. This is crucial for improving fuel efficiency, increasing payload capacity, and enhancing the performance of the aircraft. Additionally, the lightweight nature of aluminum sheets allows for easier handling and assembly during the manufacturing process. Secondly, aluminum has excellent corrosion resistance properties. This is crucial for aerospace applications as the components are exposed to various environmental conditions, such as high humidity, extreme temperatures, and exposure to chemicals. The corrosion resistance of aluminum ensures the longevity and durability of the structural components, reducing the need for frequent maintenance and replacement. Furthermore, aluminum is a highly malleable material, allowing for easy shaping and forming into complex structures. It can be easily bent, cut, and fabricated to meet specific design requirements, making it versatile for various aerospace applications. The ability to form complex shapes with aluminum sheets enables engineers to design efficient and streamlined structures, optimizing aerodynamics and minimizing drag. Another advantage of aluminum sheets is their excellent thermal conductivity. This property allows for efficient heat dissipation, which is crucial in aerospace applications where components may be exposed to high temperatures generated during flight or engine operation. The thermal conductivity of aluminum helps prevent overheating and ensures the structural integrity of the components. In conclusion, aluminum sheets are highly suitable for aerospace structural components due to their lightweight, corrosion resistance, malleability, and thermal conductivity properties. These characteristics make aluminum an ideal material for various applications in the aerospace industry, contributing to the overall performance, efficiency, and safety of aircraft.

- Q:Are aluminum sheets suitable for chemical reactors?

- Depending on the specific application and conditions, aluminum sheets can be suitable for chemical reactors. Aluminum is known for its excellent corrosion resistance, particularly when exposed to air or water, thanks to the formation of a protective oxide layer. This quality makes it appropriate for many chemical reactions involving non-aggressive substances. However, it's important to note that aluminum may not be suitable for reactors that handle highly acidic or alkaline solutions. Such solutions can corrode the oxide layer and cause the metal to degrade. Furthermore, aluminum may react with certain chemicals like strong oxidizers, halogens, or strong bases, which can compromise the integrity of the reactor. In situations where aluminum is used in chemical reactors, it is common to apply protective coatings or linings to enhance its resistance to corrosion and chemical reactions. These coatings serve as an additional barrier between the aluminum and the reactants, ensuring safe and effective operation. Ultimately, the appropriateness of using aluminum sheets for chemical reactors depends on the specific chemical reactions, operating conditions, and the required level of corrosion resistance. It is always advisable to consult with experts and consider material compatibility before selecting aluminum for such applications.

- Q:Are aluminum sheets suitable for signage?

- Yes, aluminum sheets are suitable for signage. They are lightweight, durable, and weather-resistant, making them a popular choice for outdoor and indoor signage applications. Additionally, aluminum sheets can be easily customized, printed, and mounted, allowing for versatile and long-lasting signage solutions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

coated aluminium coil AA3003-H16, 0.62mm thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords