CMAX Light Single Axle Shredder For PE/PP/PVC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Certification: CE,SGS,UL,TUV

1.High capacity

2.Good quality and reasonable price

Single Axle Shredder

1.Siemens PLC controlling System

2.Automatically reverse and forward Rotation

3.Overload Protect

WANROOETECH PNDS Single Axle Shredder:

Single Axle Shredder Product Description:

This model Plastic Shredder with small nibble type ripping teeth on the rotor assembly is one of the new applications being applied to the recycling industry for shredding high volume bulk materials, such as wood pallets, furniture parts, cardboard, plastic waste, garbage and many other reusable materials. Unique adjustment method for rotor and stator blades could double or even quadruple their life-span. Material is fed through the hopper in front of a hydraulically operated drawer, which pushes the material load-controlled onto the turning rotor. The material is shredded between the rotor knives and a fixed counter knife. The screen hole with different perforation diameters determines the size of shreds. Produced shreds can drop from the machine through the screen perforation directly or be removed with the optional suction device or spiral conveyor.

Single Axle Shredder Product Features:

1)Precisely processed combined frame made of extra-thick plates; Lange-angle, hexagon prism of power slewing axis; Big hopper with big caliber for feeding big material

2)PLC control system with automatic overload protection and auto reverse switch

3)Unique hydraulic pushing system accelerates the shredding speed, for light material particularly

4)Each dynamic blades has four cutting edges which enable reutilization after being abraded, by rotating 90 degree

5)Each fixed blades has two cutting edges which enable reutilization after being abraded, by rotating 180 degree

6)Quiet operation at low speed

7)Screen perforation is adjustable according to customers' requirement

8)The shredders can be adjusted according to customer specific requirements for throughput volume, material to be processed, etc.

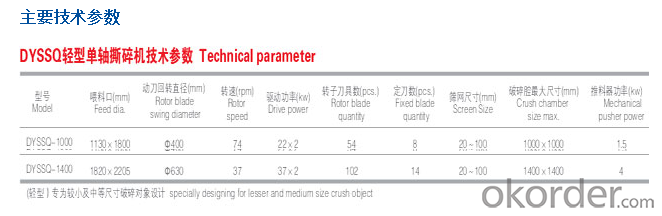

Light Single Axle Shredder Technical

To protect environment and suit for different output requirement.CNBM produce LIGHT AND HEAVY AXLE shredder.This kind of shredder is solid and wearable.It is suitable for crushing wood,different kind of plastic,plastic film and paper. Low speed rotor blade ,low noise ,high output and high save energy.

- Q:Plastic crusher is slow to eat. Why?

- The knife when the attention, it is best to wear knife, knife grinding after

- Q:How many units should be taken for processing polyethylene granules? It is better to introduce them in detail,

- That can only be used in injection molding products like plastic woven bag is used for the production of polypropylene plastic, plastic woven bag. The production of recycled plastic particles should have a certain space, used for storage and cleaning the waste plastics; the second to have a plastic crusher used for crushing waste plastic products;

- Q:Why plastic crushers are closely related to environmental protection?

- As is known to all, the decomposition of plastics is very poor. Plastic discarded, not recycled, will affect the environment. PS: we do import engineering plastics

- Q:600 of the plastic crusher, there are 18 pieces of moving blades, 4 fixed blade, want to ask the blade and the fixed blade of the gap is how much?Look, the machine seems to have become smaller from left to right. Is that so?

- Plastic crusher blades, also known as plastic machinery blades, a wide variety of high quality steel, with good sharpness and abrasion resistance. It is mainly used in plastics, rubber and other industries. As with other blades, it requires precise geometric tolerances to ensure good assembly quality.

- Q:What are the key words in plastic machinery?

- Plastic granulator, plastic granulator, plastic extruder, plastic crusher, plastic crusher, plastic granulator, foam machine, sheet material processing machine,

- Q:Maintenance essentials of 300 kW generator rental system for recycled plastics machines

- The recycled plastic crusher is the ideal plastic machinery and equipment for recycling and processing of waste plastics. The correct maintenance and maintenance is the best way to prolong the mechanical life

- Q:Is the waste plastics crusher harmful to the environment when it is produced?

- Low carbon, energy saving, low noise, tearing materials, recycling, and so on.It's the latest plastic shredder machine:

- Q:Which industries will buy crushers?

- Lime, buildings, minerals, coal, and so on, may be used more

- Q:What material should be used for the plastic crusher screen?

- The grate below the plastic crusher is made of alloy.

- Q:How to dust the plastic crushing material?

- The dust filter bag is more durable, and because of the design of negative pressure type, the fan does not touch dust, so that the utility model has the advantages of stable work, higher efficiency and longer service life. Equipped with mature fan frequency conversion device, the fan of dust removal system can automatically adjust the operating conditions according to the quantity of production equipment

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX Light Single Axle Shredder For PE/PP/PVC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products