High Output CMAX Series PB&YPS-FP Sheet,Plates,Foam Coil Material Crusher extruder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

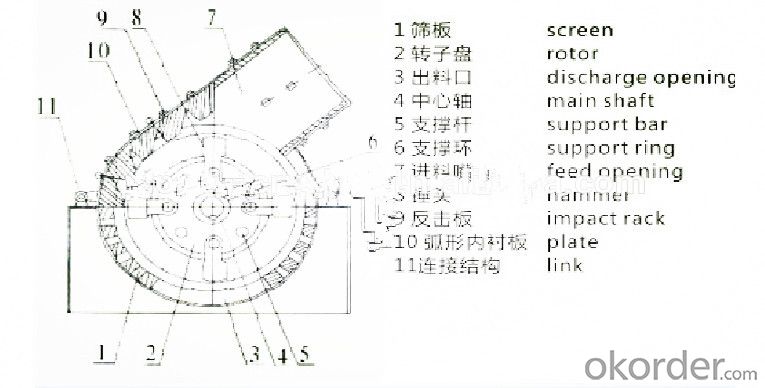

Product Description

1.can solve the problem of width of sheet,platesand foam coil materical.

2.this serice add a set of haul-off device,two sets of press roller,air press controller.

3.the line speed can reach 30m/min

4.capacity is higher

5.main axis is processed with high quality steel after verifying the balance.

6.the rotor adopts 'V''type cutting technology

7.the CMAX-FP adopts box water cooling system,which avoid sticking the blade because of the heating of materical.

8.we can provide material collection device and powder separation system according to customer's requirements

Specifications

Certification: CE SGS,ISO9001,UL,TUV

1.High capacity

2.Good quality and reasonable price

Our Services

1) Presale service: Freely provide project designing, process designing, choosing suitable equipment for you.

2) Mediumsales service: Accompany you to complete the acceptance of the equipment,draft the construction scheme and detailed process, and complete process of export

3) Aftersales service: We sent engineer to the scene to guide installation, debugging and training operators.

4) we provide engineers available to service machinery overseas

product show

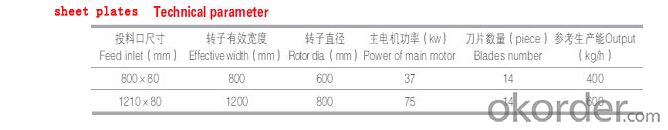

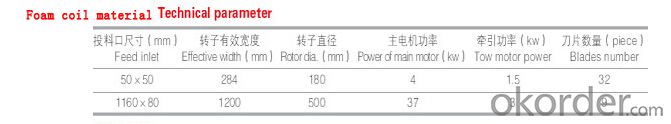

technical data

sheet plates technical

foam coil materical

FAQ:

*Q: What’s the price of this machine please?

*A: Dear customer, for each kind of our machines, we have lots of models.

Generally speaking, we design the production lines according to

different requirements of different machines from different customers.

Therefore, the prices are different. So please kindly inform us your requirements.

For example, the raw material, the output product size, capacity and etc.

The more detailed, the better. Our Engineers will design a suitable production line for you.

- Q:Hello everyone! I am engaged in waste plastics crushing a small factory repelleting, I have a crusher is crushing all kinds of waste plastic bottles, plastic blocks and pipes, with cleaning one broken, can put the screen into big hole, and then smash PP and PE agricultural waste sacks film can be used? You have experienced elder brother to help, thank you little brother

- Aimed at crushing PP waste woven pockets and PE agricultural film to be accurate crusher, and the quality of the tool is better. The structure of the woven sack crusher must be more dense, and it must be prevented from winding. The size of the screen hole determines the grain size.

- Q:PVC how much is a plastic crusher?

- Recommend direct consultation with manufacturers, and more contrast.

- Q:What kind of heating machine is better for the recycled plastics factory? How long does the crusher sink need to be cleaned?

- Your shaft is broken. Is it too deep at the bottom of the bar to eat too much? The exhaust is empty and the material is normal

- Q:What are the key words in plastic machinery?

- Plastic cleaning machine, plastic conveyor, plastic feeding machine, plastic processing machine, plastic recycling machine, plastic processing machine, waste plastics granulator,Waste plastic granule machine, waste plastics extruder, waste plastics processing machine, waste plastics recycling machine, waste plastics machinery, waste plastics equipment, plastic machinery,Plastic equipment, foam granulator, foam granule machine, foam processing machine, foam recovery machine, foam recycling machine, regeneration foam machine, waste foam machine

- Q:What type of crusher is good for heavy crusher?

- The utility model has the advantages of large crushing ratio, no material blocking, simple structure, high yield, low investment, good grain shape and difficult to be crushed. In the processing of medium and hard materials

- Q:Maintenance essentials of 300 kW generator rental system for recycled plastics machines

- Maintenance method: 1, plastic crushing machine should be installed ventilation position, to ensure that the work of heat distribution, and extend its life. 2, should be regularly filled with lubricating oil bearings, to ensure the lubrication between bearings. 3, regular inspection tool screw, new recycled plastic crusher after 1 hours of use, with the fastening tool knife, knife set screws, strengthen fixed blade and tool.

- Q:In hard rock foundation construction, can not be carried out burst, crusher does not move. Is there any good way?

- Cutting machine cutting width; or hammer drilling; then using hydrochloric acid into the reaction -- let

- Q:What material should be used for the plastic crusher screen?

- Screen mesh is generally made of wear-resistant steel, should be better point.

- Q:How to dust the plastic crushing material?

- The dust filter bag is more durable, and because of the design of negative pressure type, the fan does not touch dust, so that the utility model has the advantages of stable work, higher efficiency and longer service life. Equipped with mature fan frequency conversion device, the fan of dust removal system can automatically adjust the operating conditions according to the quantity of production equipment

- Q:How many categories are there in the cutter type of plastic crushers?

- 1 、 all steel welded frame, durable2, easy disassembly design, easy cleaning and maintenance3 、 imported steel cutting tools, sharp blade, easy to change, durable4, grinding all kinds of soft and hard plastic, easy and easy5. It is equipped with motor winding and interlock protection system to ensure safe use6. The minicomputer is equipped with pulleys for easy movement. The large machine has a water cooling system for easy time operation7, you can choose different tools and different hole through the screenClaw knife plastic crusher is suitable for all kinds of plastic pieces of recycle, especially for all kinds of rigid plastic (such as material, shoe material) better.Flat knife plastic crusher

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Output CMAX Series PB&YPS-FP Sheet,Plates,Foam Coil Material Crusher extruder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products