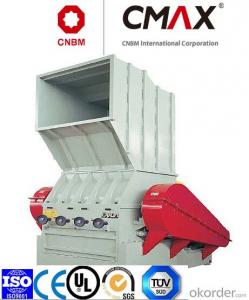

plastic shredder plastic crusher plastic crushing machine for sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Fully airtight silent designed noise below 80db without 1m away from the machine,

avoids powder contamination;

2. Elegant designed with options available;

3. Installed with heat transmitting system, expel heat generated from the electric motor,

protection and safety without any problem for long hour's operation;

4. Stainless steel material storage tank easy for cleaning and remove, stainless steel

suction spout available upon require;

5. Installed with safety protection system and CE authenticated electrical appliances

meeting the European safety standard;

6. Installed with electrical phase controller and power isolator, safety operation and

simple maintenance;

7. Installed with power isolator, safety operation and simple maintenance;

8. Movable stainless steel multi-positional tray feed and closed for complete soundproof

operation.

- Q:How many units should be taken for processing polyethylene granules? It is better to introduce them in detail,

- Third to have a drainage exhaust plastic extruder, used to contain water, exhaust, old plastic heating plasticization, melt extrusion plastics; the fourth to have a simple plastic extruder, after first extrusion of molten plastic after two extruded into the thin; fifth to the cooling water tank and a cutter the filament, cooled and cut into particles. The technological process is as follows:Selection, classification and cleaning of waste plastics: extrusion, plasticization, cooling, cutting and packingIf a set of extrusion granulation equipment has 20~30 square meters, the workshop is enough, but the outside of the site requires a little bigger, and at least one hundred square meters

- Q:Classification of equipment for plastics mills

- (two) powerful plastic crusher:1. The blade structure is between the claw knife and the flat knife. It is suitable for crushing the ordinary sheet, pipe, profile, plate and packing materials and other plastic products;2, universal plastic crusher, using sealed bearings, so that the rotation of the bearings for a long time to maintain good;3, design a reasonable knife, using steel blade, knife product granulating uniform, thermal processing, and through strict balance test, elegant appearance design;

- Q:Why plastic crushers are closely related to environmental protection?

- Plastic recycling has developed, and that has important implications for environmental protection

- Q:How do you melt plastics?I would like to waste plastic (such as: pots, shells), melting and forming, as a useful equipment shell (such as: sound shell). But plastic is non crystal, how to melt like a crystal, please advise!

- It can be heated by plastic injection molding machine. The molten plastic is injected into the corresponding mold at higher pressure. After cooling and shaping, the product is removed

- Q:What are the key words in plastic machinery?

- Plastic granulator, plastic granulator, plastic extruder, plastic crusher, plastic crusher, plastic granulator, foam machine, sheet material processing machine,

- Q:Is the waste plastics crusher harmful to the environment when it is produced?

- Bittersweet! Properly handled, it is good for the environment.What do I say?

- Q:What material should be used for the plastic crusher screen?

- A plastic crusher is a high speed rotating cutting and crushing plastic, which is different from a rock crusher with a hammer head.

- Q:What does the crusher crush add to the weight of the crushing material?

- In fact, glass fiber reinforced plastic can also be regarded as a kind of plastic, although it is better than ordinary plastic strength, to be resistant, after all, it contains a lot of resin. If you want to break to about a centimeter, you can use Reed's single shaft crusher, lower production, but less investment. If you want to break to more than two centimeters, and the output is large, it is recommended to use Sred powerful biaxial crusher. The two machines are free of dust and low noise.

- Q:How to dust the plastic crushing material?

- The dust removal system always operates in the most energy-efficient condition. The system comes with explosion-proof and explosive discharge devices, so that the use of more secure. The structure of this system is modular composite structure, each component has been strictly chemical derusting, degreasing, phosphating, paint, paint, aesthetic texture, corrosion resistance. Basic parameters: handling air flow: 2500m3/h--100000m3/h. running resistance: lower than 1000pa. emission index: lower than 80ml/m3., core components imported, 3 years free maintenance

- Q:What's the difference between a domestic crusher and another crusher?

- According to the different manufacturing process, it can be divided into crawler mobile crushing station and tire mobile crushing station.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

plastic shredder plastic crusher plastic crushing machine for sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords