High Output CMAX Series Low Noise Crusher For All Types of Pipe/Sheet Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1.can solve the problem of width of sheet,platesand foam coil materical.

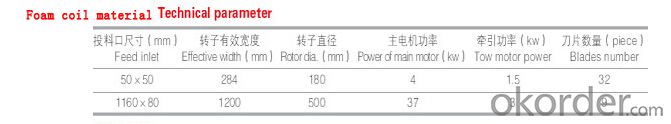

2.this serice add a set of haul-off device,two sets of press roller,air press controller.

3.the line speed can reach 30m/min

4.capacity is higher

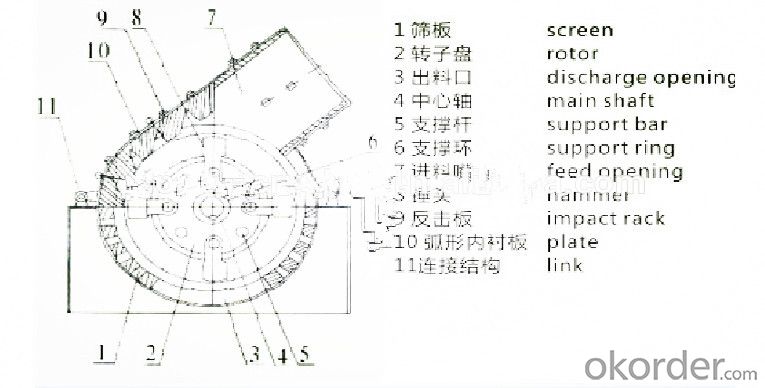

5.main axis is processed with high quality steel after verifying the balance.

6.the rotor adopts 'V''type cutting technology

7.the CMAX-FP adopts box water cooling system,which avoid sticking the blade because of the heating of materical.

8.we can provide material collection device and powder separation system according to customer's requirements

Specifications

Certification: CE SGS,ISO9001,UL,TUV

1.High capacity

2.Good quality and reasonable price

Our Services

1) Presale service: Freely provide project designing, process designing, choosing suitable equipment for you.

2) Mediumsales service: Accompany you to complete the acceptance of the equipment,draft the construction scheme and detailed process, and complete process of export

3) Aftersales service: We sent engineer to the scene to guide installation, debugging and training operators.

4) we provide engineers available to service machinery overseas

product show

technical data

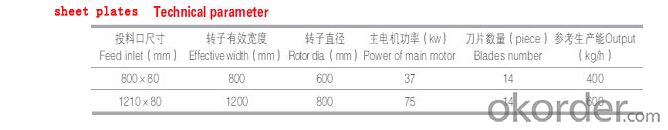

sheet plates technical

foam coil materical

FAQ:

*Q: What’s the price of this machine please?

*A: Dear customer, for each kind of our machines, we have lots of models.

Generally speaking, we design the production lines according to

different requirements of different machines from different customers.

Therefore, the prices are different. So please kindly inform us your requirements.

For example, the raw material, the output product size, capacity and etc.

The more detailed, the better. Our Engineers will design a suitable production line for you.

- Q:Plastic crusher does not eat what is the reason?

- Film, oiler, head of fast feed..... What type of crusher is used?...

- Q:How much does a small plastic crusher cost?

- I suggest that specific production look, or else can not quote, or consult the manufacturers.

- Q:Classification of equipment for plastics mills

- Plastic crusher in the injection molding industry, also known as: plastic crusher. There are three main categories:(1) hard plastic crusher, this machine is suitable for crushing all kinds of small and medium plastic sheets:1, ABS, PE, PP board and other plates crushed recovery;2. The rectangular feeding port designed for the crushing of plate materials is convenient for crushing long strip plates and improves work efficiency. The utility model can be matched with a suction fan and a storage barrel to form a plate crushing and recovering system, and the recycling efficiency can be more fully utilized;3, the use of sealed bearings, bearing rotation for a long time to maintain good; knife design is reasonable, the product even granules; knife stand heat shrinkable treatment, shape design beautiful and generous;

- Q:600 of the plastic crusher, there are 18 pieces of moving blades, 4 fixed blade, want to ask the blade and the fixed blade of the gap is how much?Look, the machine seems to have become smaller from left to right. Is that so?

- It requires the choice of the chemical composition of the blade material suitable for different requirements of the user and crushing different objects. It requires a suitable blade angle that keeps the edge of the blade sharp and allows the blade to have a certain strength instead of collapsing during use. It requires a good heat treatment process to achieve the blade's hardness and very little internal stress. The plastic shredder blade will not deform during use.

- Q:Plastic grinding machine mainly grinding PVC grinding material thickness of about 20 silk finger cover size, which kind of pulverizer is suitable for this purpose?

- Overview of plastic grinding machine compared with the same type of milling machine, under the same power output is greatly improved (increased by 20%-50%), saving about energy consumption of the dust collector is added to effectively reduce dust pollution, the discharging of the main fan reduces the labor intensity of workers and open the door cover of the host can be replaced, which is convenient for maintenance and the tool windand watercooling system reduce the working temperature inside the machine body, the grinded material uneasy degeneration

- Q:What type of crusher is good for heavy crusher?

- The machine can replace the traditional jaw crusher and counterattack crusher two stage crushing, the user can save a lot of investment in equipment, and can produce grain shape excellent products.

- Q:Which industries will buy crushers?

- Gravel factory, sand making factory. Will buy a crusher. I suggest that we buy a crusher and buy Xin Yun heavy industries. Quality assurance is king..

- Q:How much does it cost to run a disposable plastic basket factory?

- Do this line of investment is relatively large, high technology, management should also keep abreast of it. In addition, the volume of products is still large enough to make money.

- Q:What's the price of used plastic crushers?

- Like Shanghai Donglong good what. Good performance and high output. We do machine maintenance in our factory

- Q:What is the noise produced by a plastic crusher?

- Low noise, mainly used for all kinds of thick wall plastic industry waste material, recycling scrap pieces, the thick and tough, large material (large head materials, large plastic pipe fittings, large diameter thick wall PE pipe, plastic packaging barrels, large bundles of plastic film,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Output CMAX Series Low Noise Crusher For All Types of Pipe/Sheet Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords